Nuclear power station transformer gas relay seismic test method

An anti-seismic test and relay technology, applied in the field of power transformers, can solve problems affecting the availability of transformers, misoperation of gas relays, tripping of transformers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Tested object: German TU DR80, double cylinder float type, dry reed contact

[0021] Its heavy gas action principle is to connect the oil flow in the pipe to the connection baffle of the heavy gas float, the connection baffle drives the heavy gas float down, and the dry reed contact in the float closes to connect the heavy gas protection circuit.

[0022] Test Results:

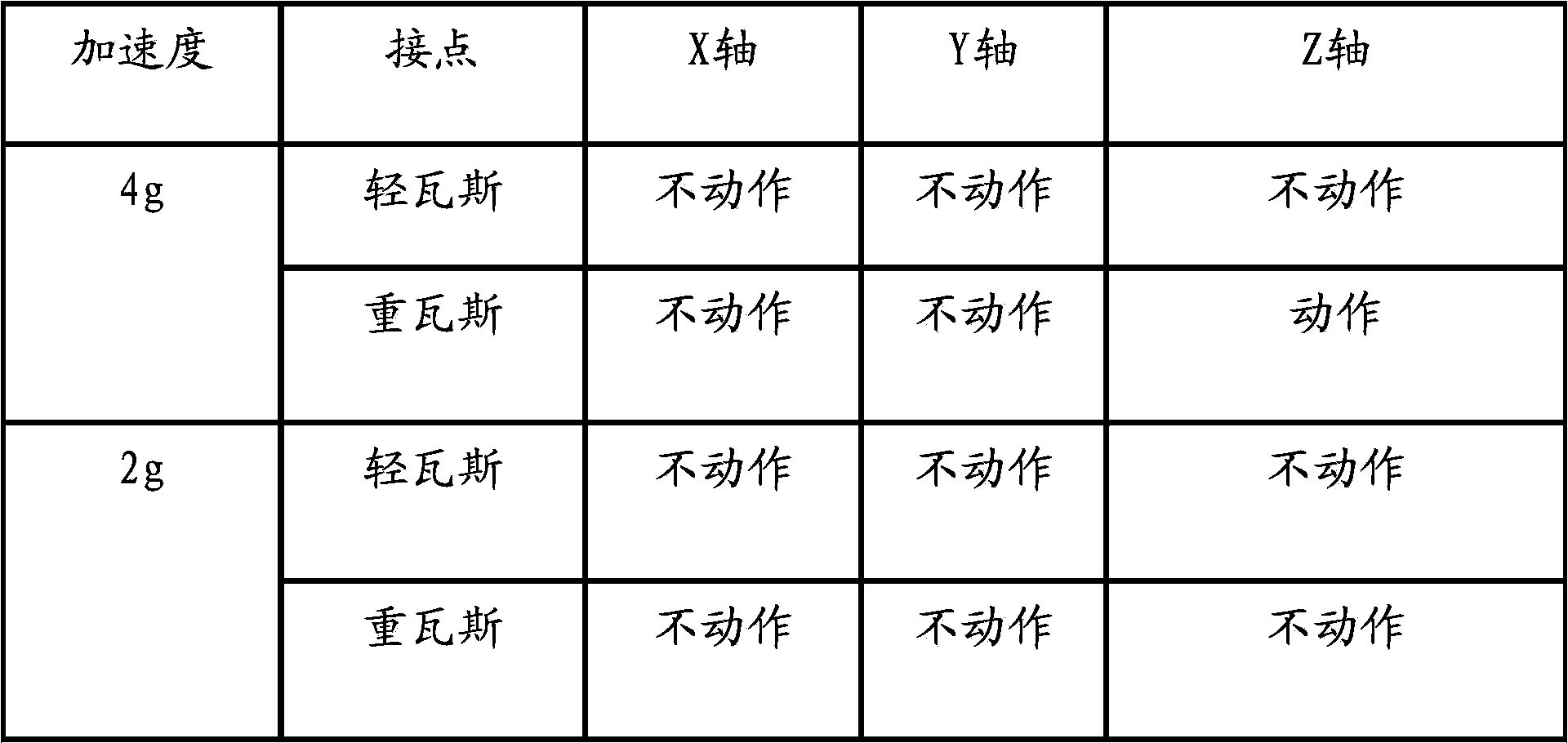

[0023] Frequency sweep test:

[0024]

[0025] Fixed frequency test: pass

Embodiment 2

[0027] Test object: UK P & B Weir 3DE / HF2, double float type, mercury contact

[0028] The principle of its heavy gas action is that the oil flow hits the baffle on the floating block, and the baffle drives the mercury contact in the floating block to connect the heavy gas tripping circuit.

[0029] Test Results:

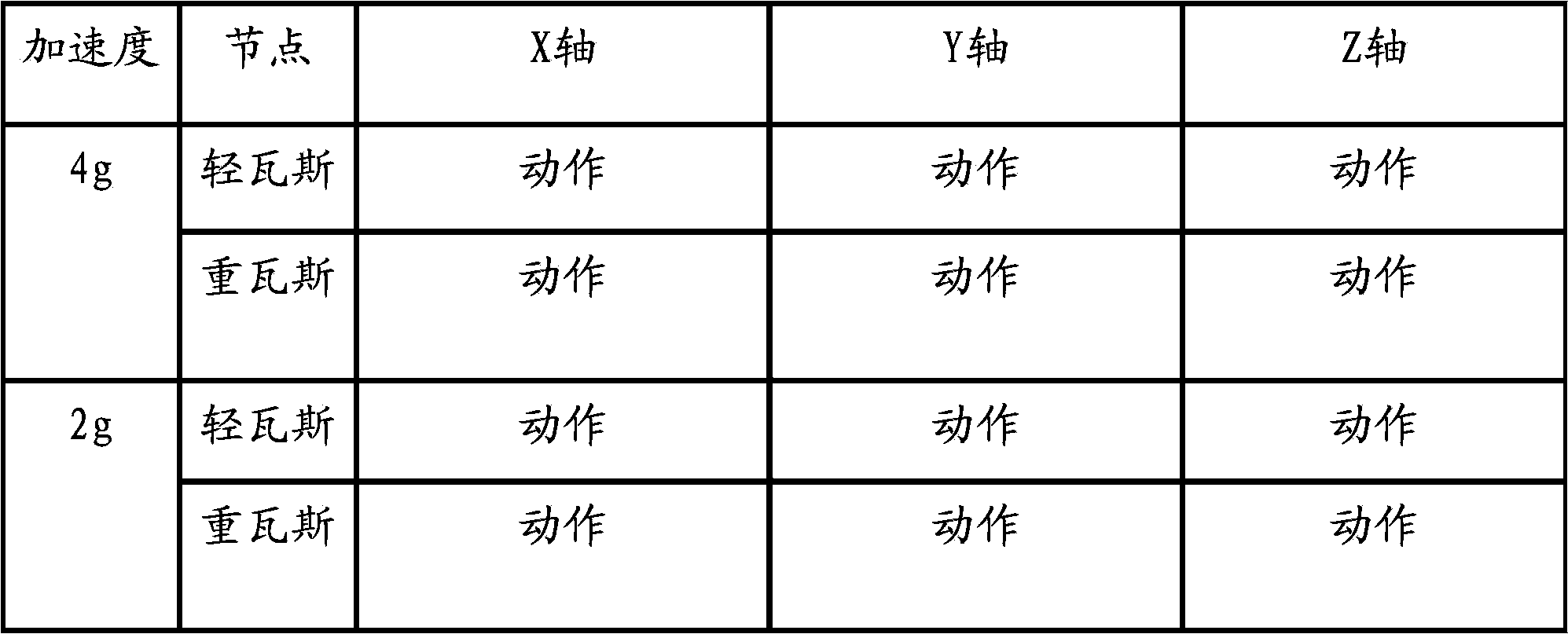

[0030] Frequency sweep test:

[0031]

[0032] Fixed frequency test: pass

Embodiment 3

[0034] Test object: domestic QJ-80, spring baffle type, dry reed contact

[0035] The principle of its heavy gas action is that the oil flow impacts the baffle, and the baffle drives the inner contact of the reed switch to attract with the magnet to connect the heavy gas tripping circuit.

[0036] Test Results:

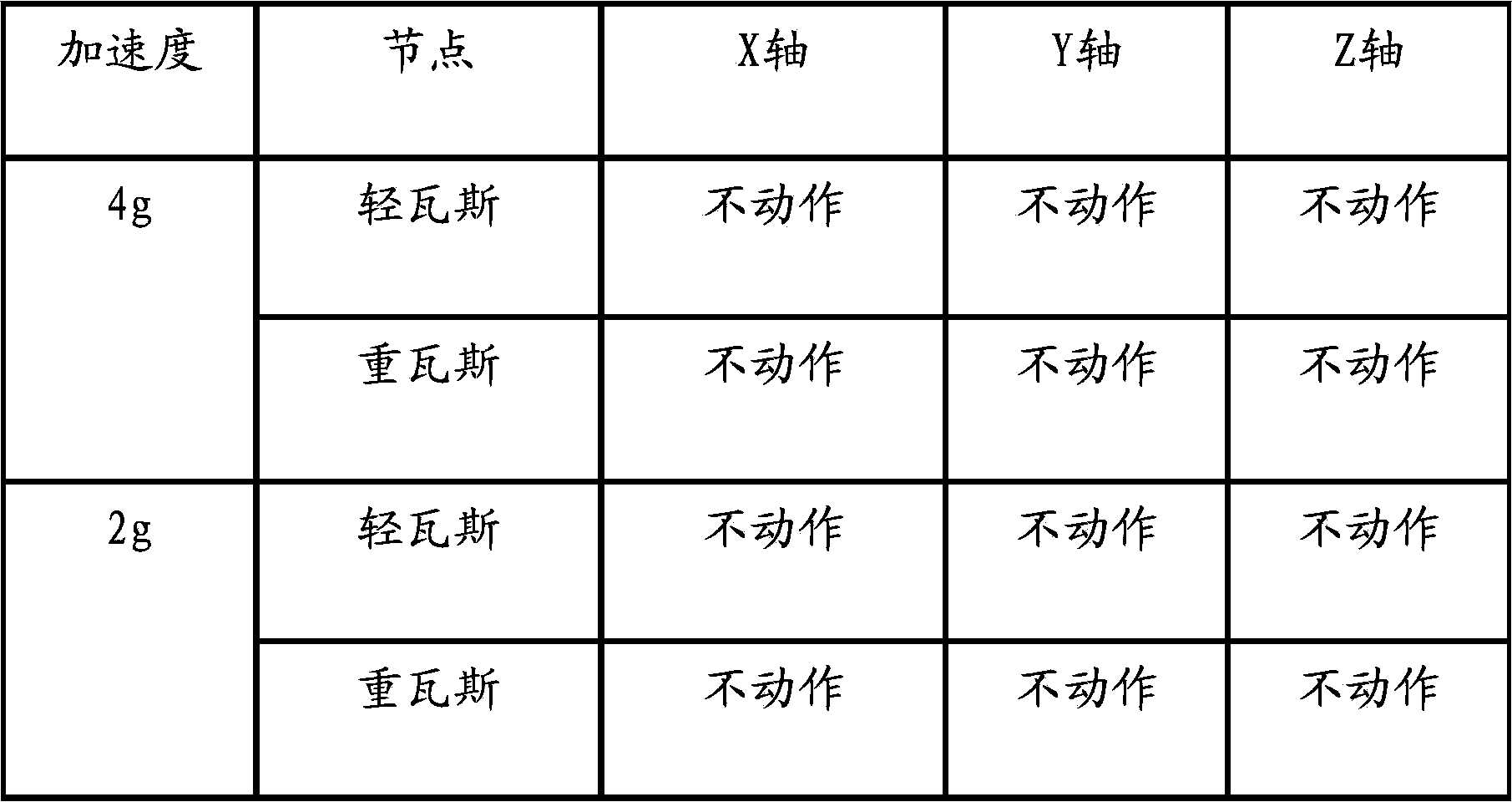

[0037] Frequency sweep test:

[0038]

[0039] Fixed frequency test:

[0040] Due to the different structures of gas relays, there is no uniform standard for shock resistance of gas relays in the world, and the vibration standards provided by various gas relay manufacturers are different:

[0041] Domestic gas relay (only applicable to QJ series gas relay with magnet baffle type and reed contact structure): comply with the national standard: 4~20Hz, acceleration 4g;

[0042] Germany EMB (double floating ball type, reed contact): 2~200Hz, the acceleration is 2g;

[0043] German TU (double cylinder float type, reed contact): 5 ~ 15Hz, the acceleration is 2g;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com