Servo welding slide table mechanism

A sliding table mechanism and servo motor technology, which is applied in welding equipment, welding accessories, arc welding equipment, etc., can solve the problems that the position of the joint table cannot be fixed accurately, cannot be used for robot welding, and the joint table cannot be flexible, etc., so as to shorten the development cycle , reduce the import cost, flexible, convenient and fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

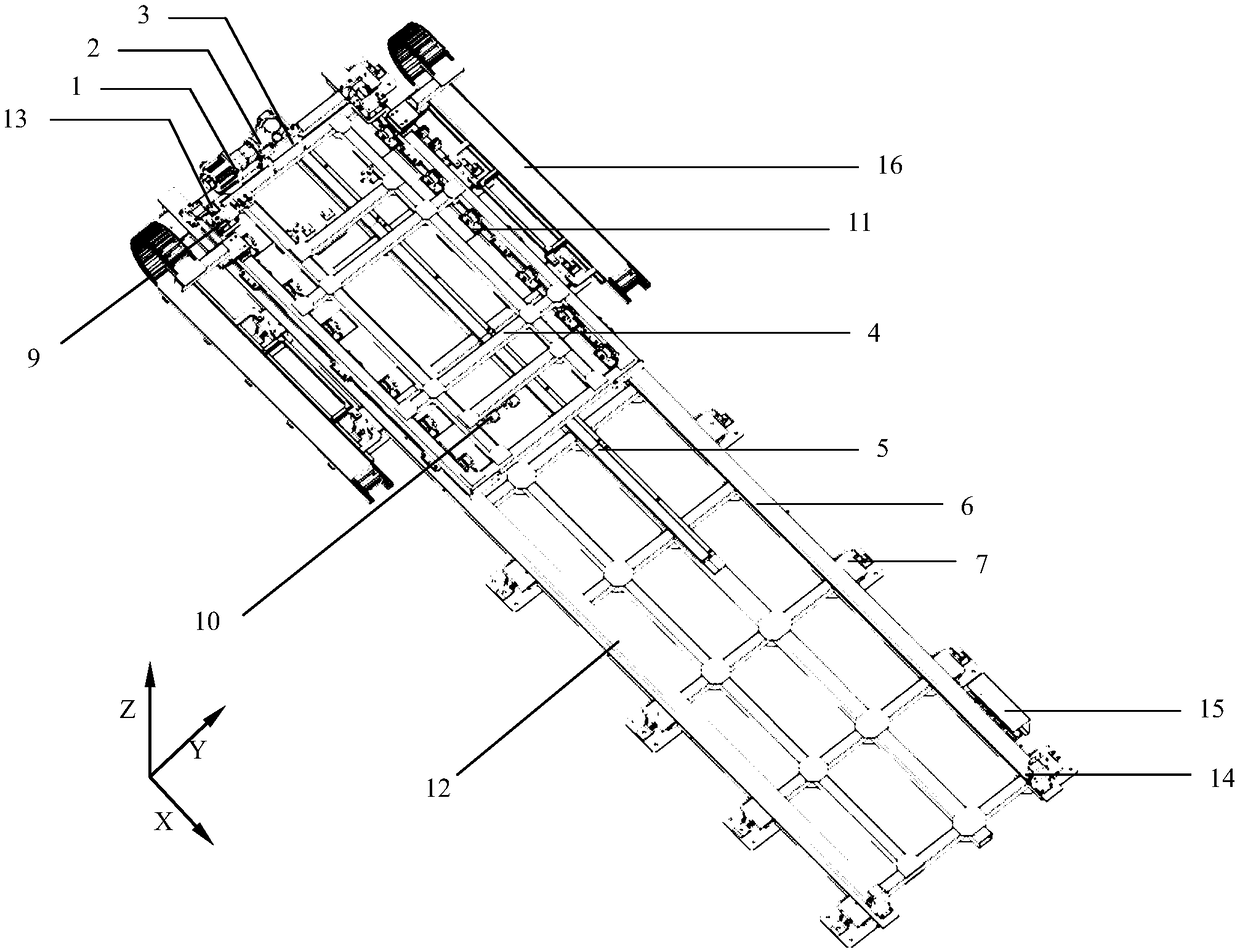

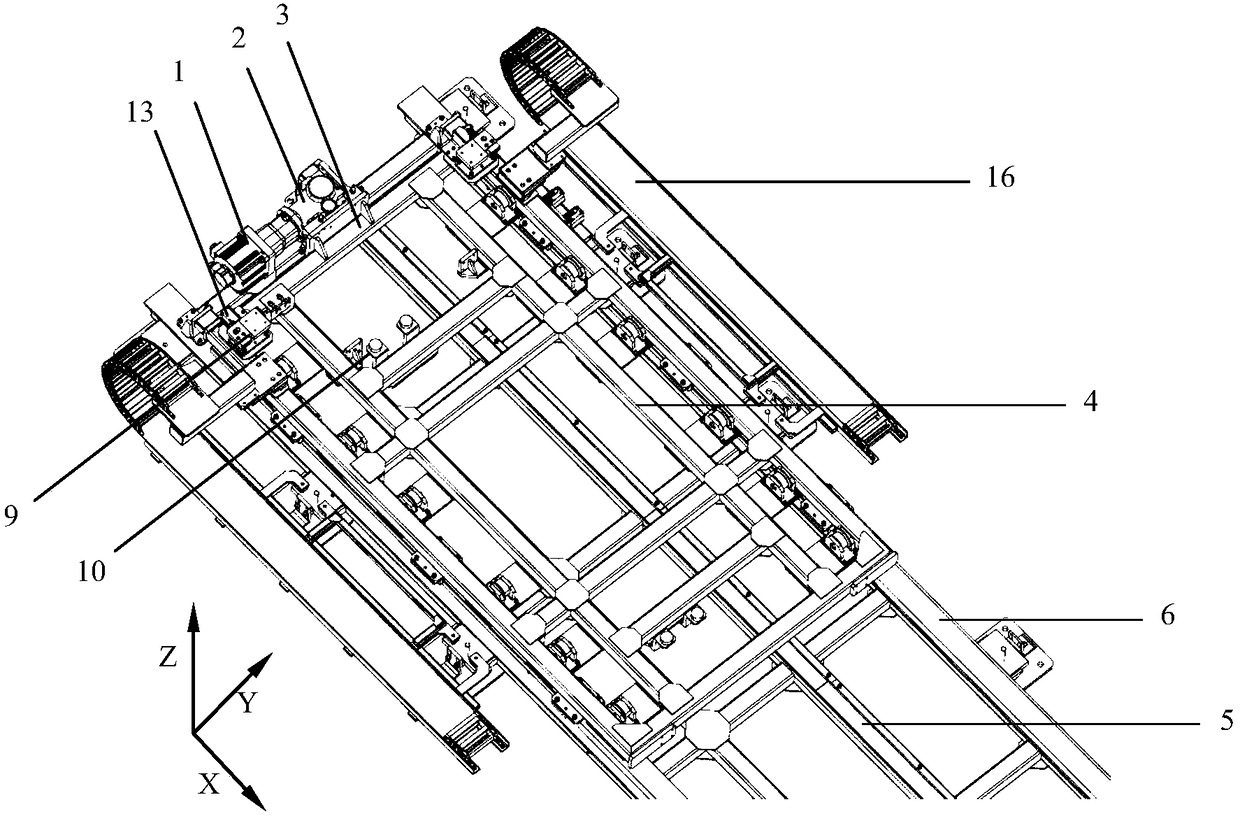

[0036] Such as Figure 1-7 10 shows a servo welding sliding table mechanism, including a sliding table control terminal, a servo motor 1, a servo motor gearbox 2, a gearbox output gear 3, a sliding table transplanting trolley 4, a sliding table rack 5, a sliding table Table slide rail 6, slide table fixed base 7, slide clamp 8 and slide clamp positioning pin 9.

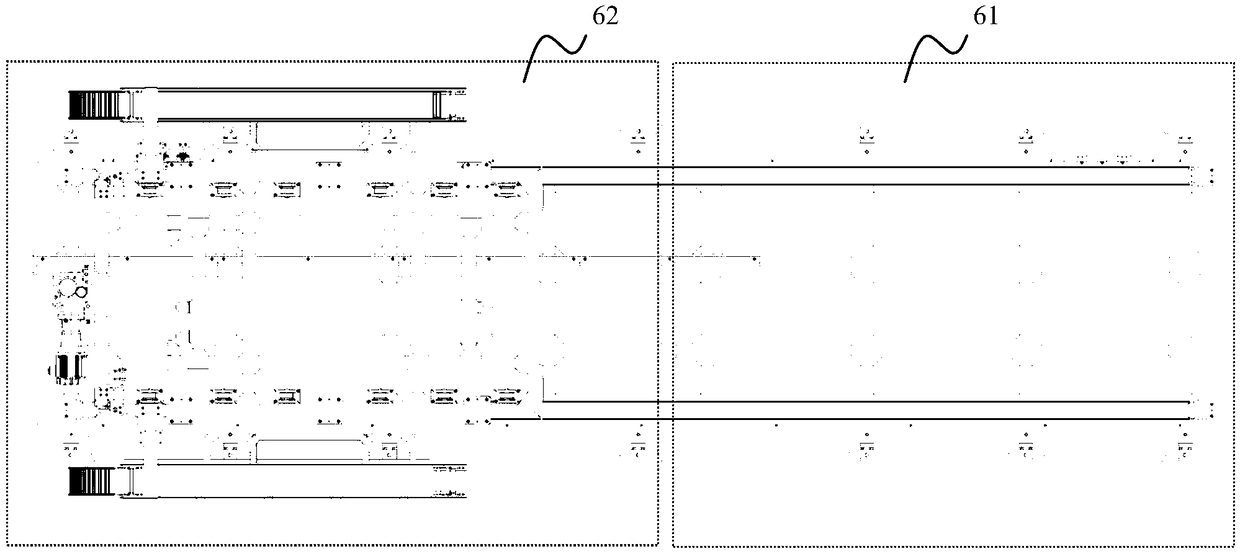

[0037] Among them, the sliding table rack 5 and the sliding table sliding rail 6 are all arranged on the sliding table fixed base 7 and laid along the X direction, the sliding table transplanting trolley 4 is arranged on the sliding table sliding rail 6, and the sliding table sliding rail 6 Equipped with a mounting position 61 and a welding position 62 ( image 3 ).

[0038] When working, the control terminal of the slide table outputs a signal to the servo motor 1, the servo motor 1 rotates, and the rotation is transmitted to the gearbox output gear 3 through the servo motor gearbox 2, and the gearbox output gear 3...

Embodiment 2

[0055] On the basis of Embodiment 1, this embodiment adopts the production mode of two servo welding slide mechanisms of the present invention and one station, that is, two servo welding slide mechanisms are set up side by side along the X direction, and one servo welding slide mechanism When the sliding table transplanting trolley of the sliding table mechanism moves to the loading position for operation, the other sliding table transplanting trolley of the servo welding sliding table mechanism moves to the welding position for operation. The loading and welding are both correct, which is very suitable High-tac production.

[0056] This embodiment has been successfully applied to the Baojun Frame 1, Frame 2, Frame 3 and Dongche flexible line projects, such as Figure 8-9 shown.

[0057] This embodiment solves the problems of difficulty in switching flexible production of multiple models, production line site and personnel utilization, ergonomics, safety hazards, etc., and is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com