Motor lead for new energy pure electric vehicle

A technology for pure electric vehicles and electric motors, applied in circuits, electrical components, insulated cables, etc., can solve the problems of low reliability, short service life, and low softness, and achieve excellent oil resistance, good adaptability, and softness good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to enable the public to fully understand the technical essence and beneficial effects of the present invention, the applicant will describe in detail the specific implementation of the present invention below in conjunction with the accompanying drawings, but the applicant's description of the embodiments is not a limitation to the technical solution. Changes in the form of the inventive concept rather than in substance should be regarded as the protection scope of the present invention.

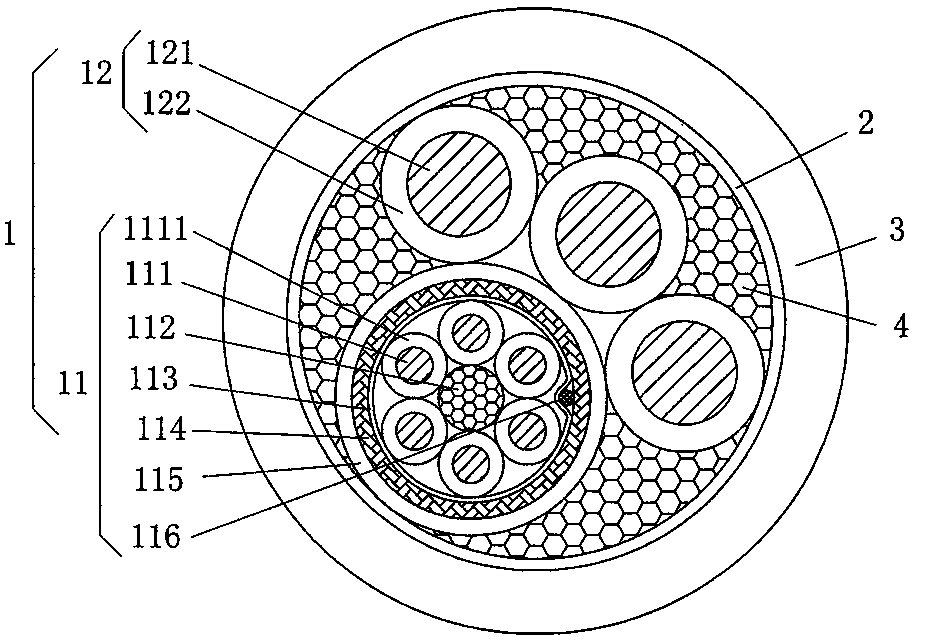

[0019] see figure 1 , a motor lead wire for a new energy pure electric vehicle, comprising a cable core 1, a release paper 2 extruded outside the cable core 1, and an outer sheath 3 outside the release paper 2. The cable core 1 is formed by twisting a signal cable core 11 and a set of power wires 12 . The signal cable core 11 includes a set of signal cores 111 each extruded with a coating layer 1111 , a filler strip 112 , a wrapping layer 113 , a braiding layer 114 , an ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com