Magnet building block structure

A technology of building blocks and magnetic attraction, which is applied in the field of splicing building blocks, can solve the problems of unfavorable mass production, complicated procedures, and difficult mold development.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

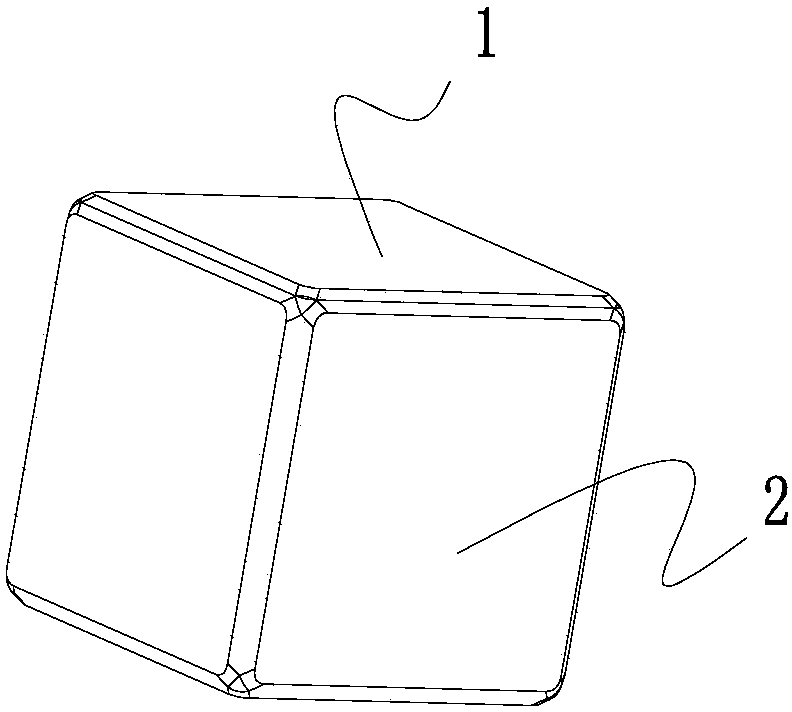

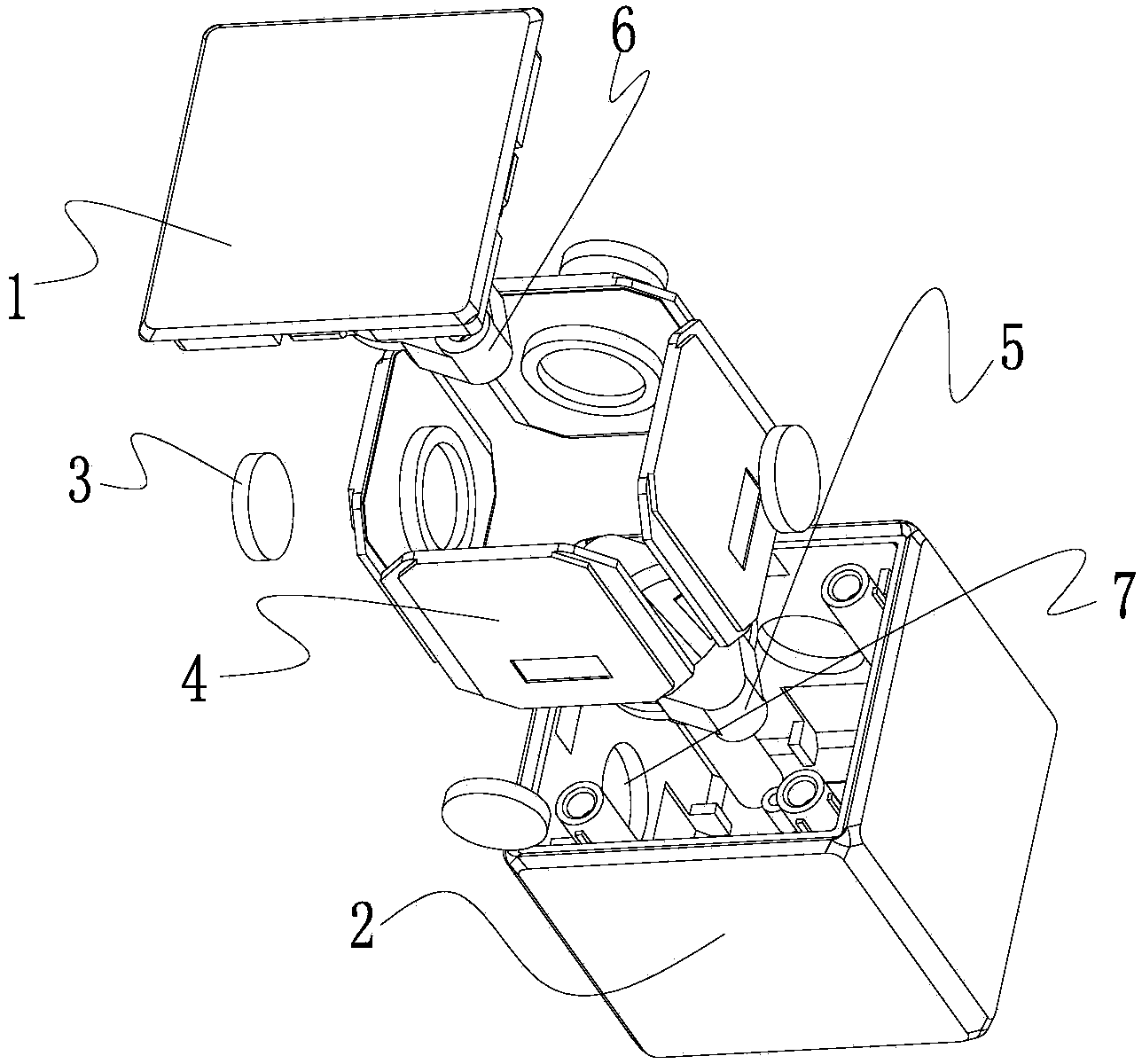

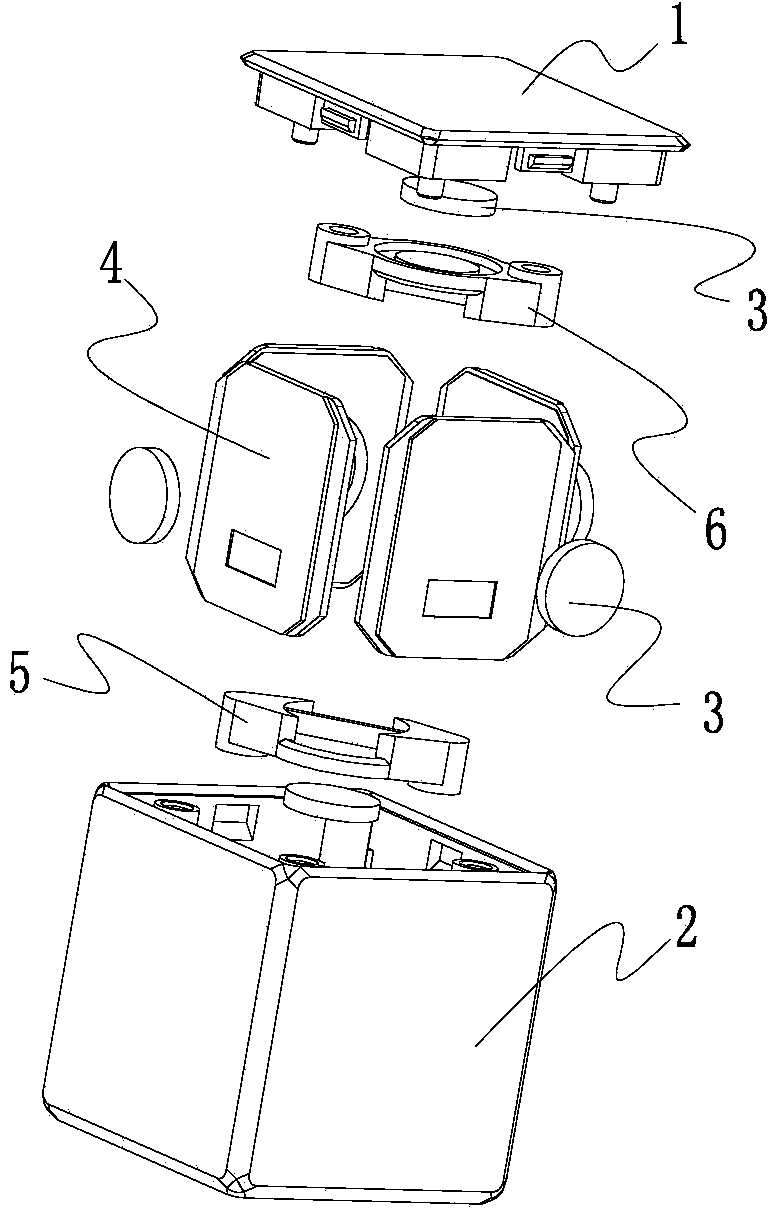

[0035] A kind of magnetic attraction building block structure that the present invention relates to, its described building block is a polyhedron, such as figure 1 , 6 , 8, 10, 12, 14, 16, 18, 20 shown, it can be a cube, it can also be a sector, it can also be a trapezoid or the like. Radial magnetization magnets 3 are built-in on all or part of the shell surfaces of the building blocks. After the magnets are radially magnetized, the magnetism on the surface is S-N relationship. N-S poles, the magnets are in mutual repulsion relationship. At this time, the radial magnetization magnet 3 will rotate in the inner cavity and adjust itself to the position where the magnetic poles attract each other. Any two building blocks can pass through the radial magnetization magnets. 3-phase adsorption splicing (this is mainly achieved by the adsorption between the shell surfaces with built-in magnetized magnets 3). In a preferred embodiment, the radially magnetized magnet can be a circular...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com