Multi-pulse digital control type electrospark deposition surfacing power supply

A technology of electric spark deposition and digital control, which is applied in the direction of arc welding equipment, manufacturing tools, welding equipment, etc., and can solve the problems of surfacing welding power source deposition efficiency and quality cannot be guaranteed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the drawings.

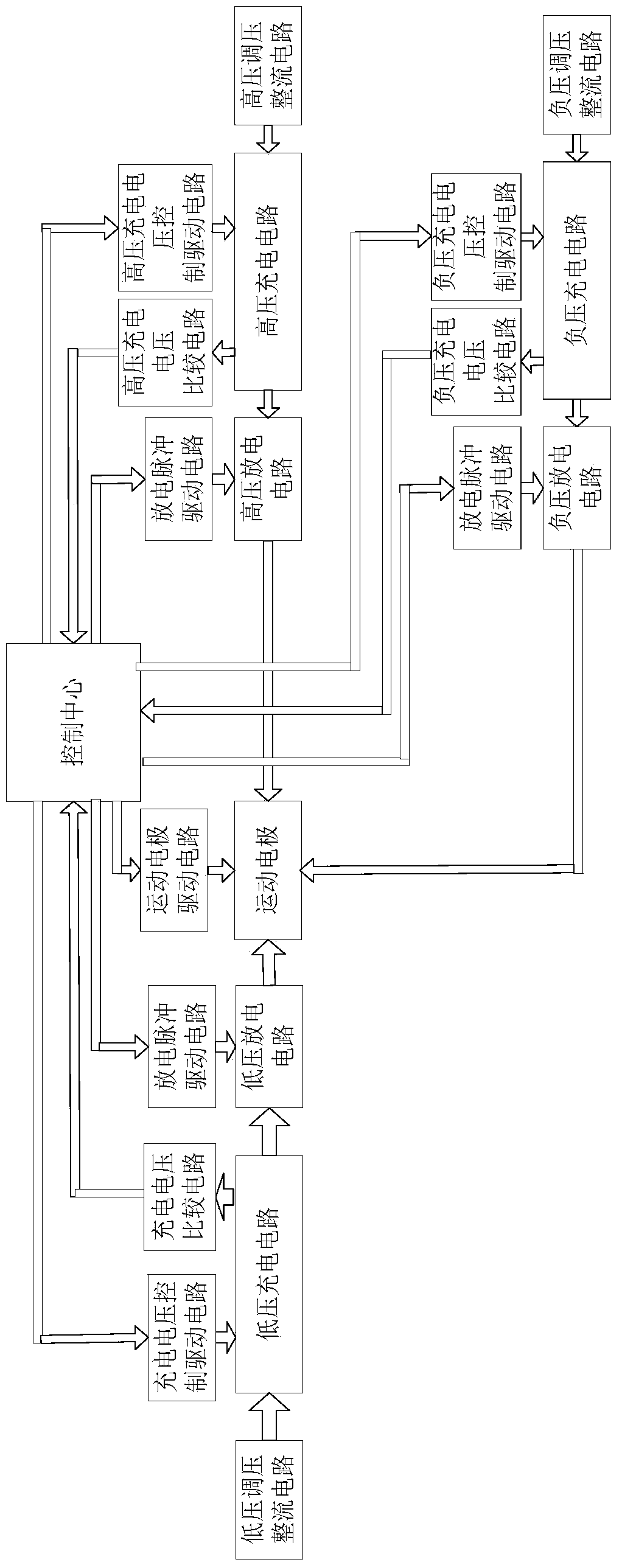

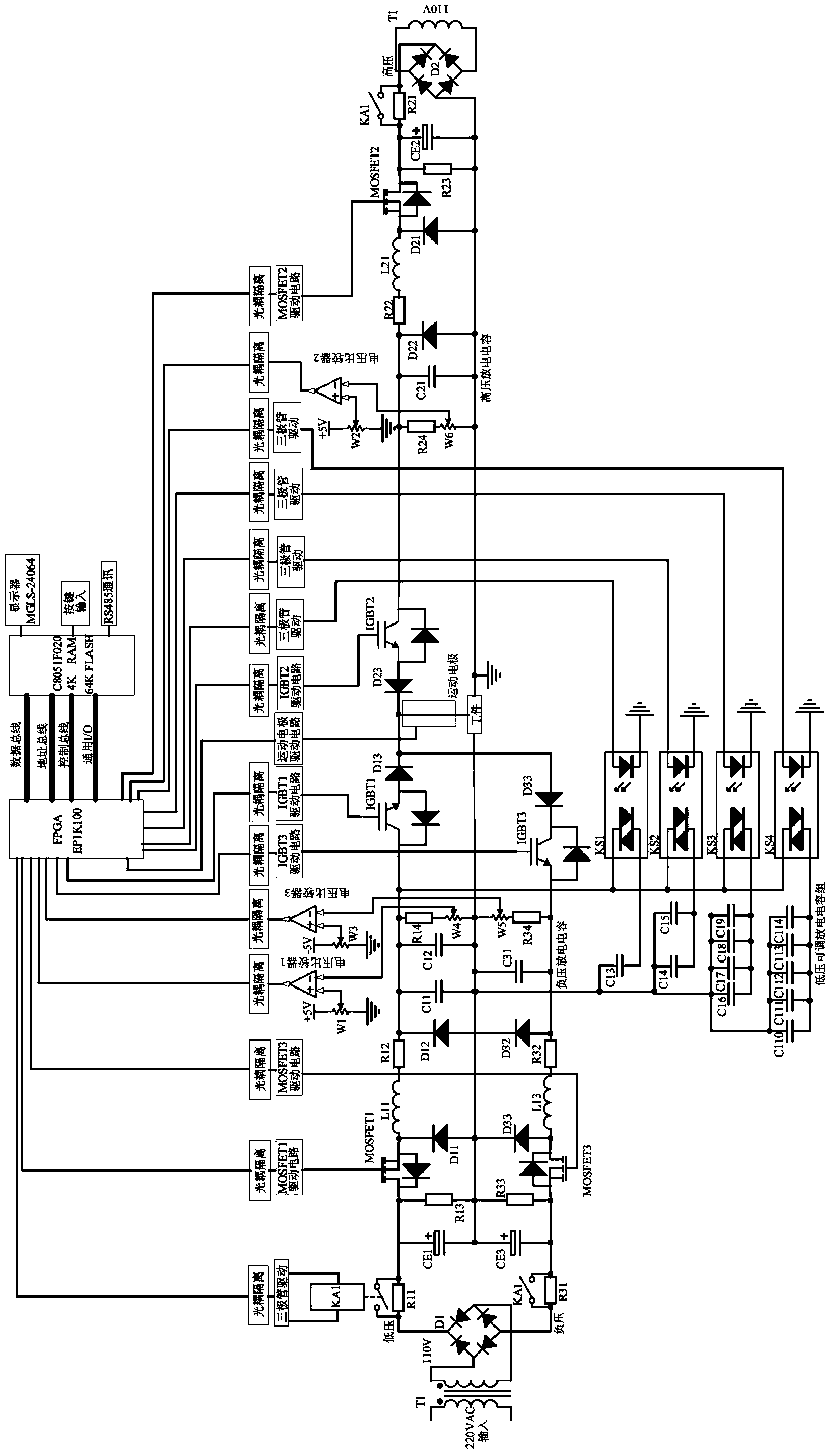

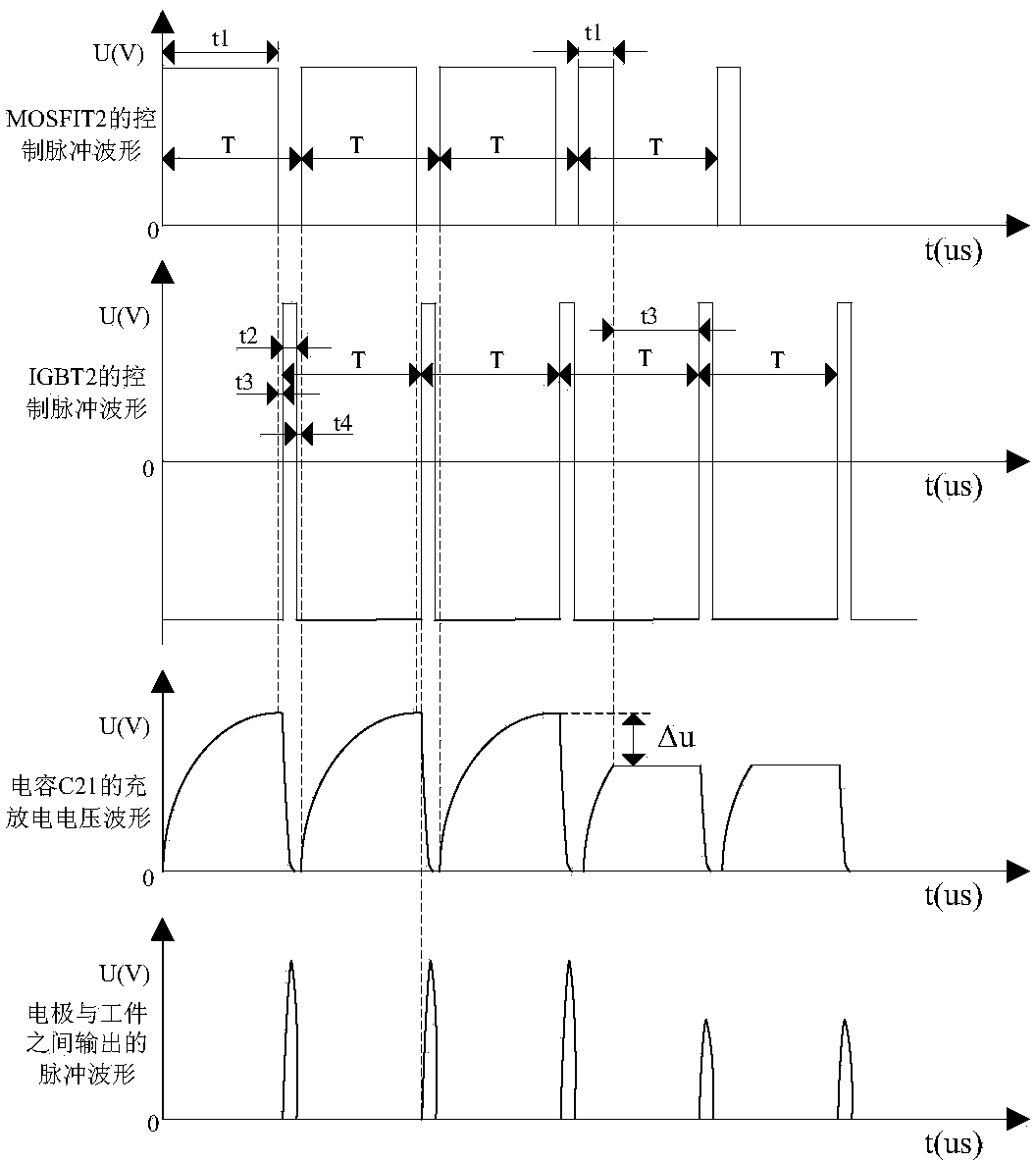

[0026] The multi-pulse digital control type electric spark deposition surfacing welding power supply of the present invention includes a first positive voltage pulse circuit, a second positive voltage pulse circuit and a negative voltage pulse circuit, the first positive voltage pulse circuit, the second positive voltage The output terminals of the pulse circuit and the negative pressure pulse circuit are connected in parallel for connecting the moving electrode and the workpiece.

[0027] The present invention adopts at least two positive voltage pulse circuits and at least one negative voltage pulse circuit. The circuit topology of the specific pulse circuit can adopt various implementation modes, such as the circuit form disclosed in Chinese Patent 201110098113.6 or Chinese Patent 201310292053.0.

[0028] The following embodiments are mainly based on the circuit topology of C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com