Dust settling and blocking preventing pipe wet concrete stirrer for underground coal mine

An anti-blocking pipe and concrete technology, which is applied in cement mixing devices, clay preparation devices, chemical instruments and methods, etc., can solve problems such as blocking pipes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

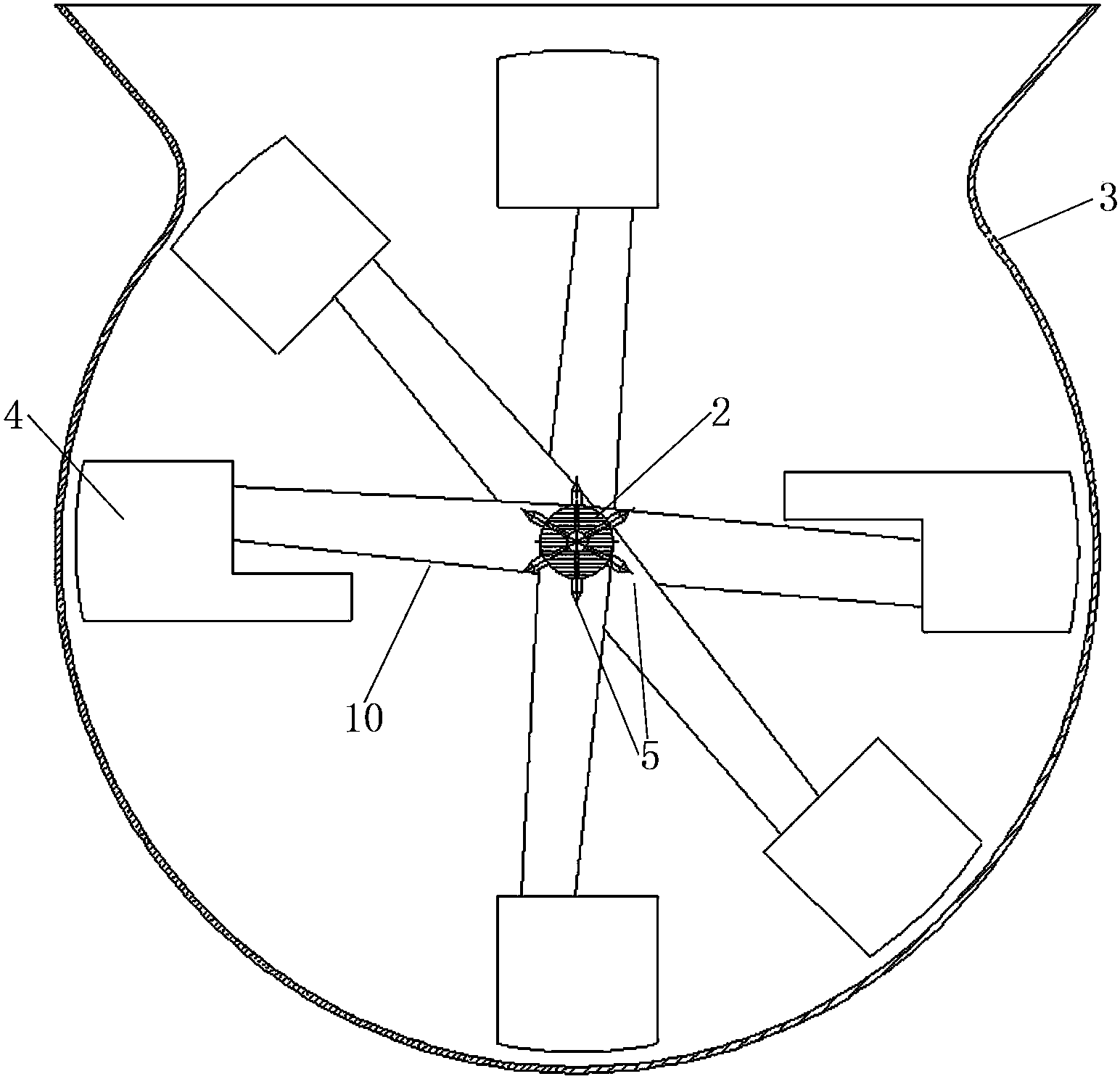

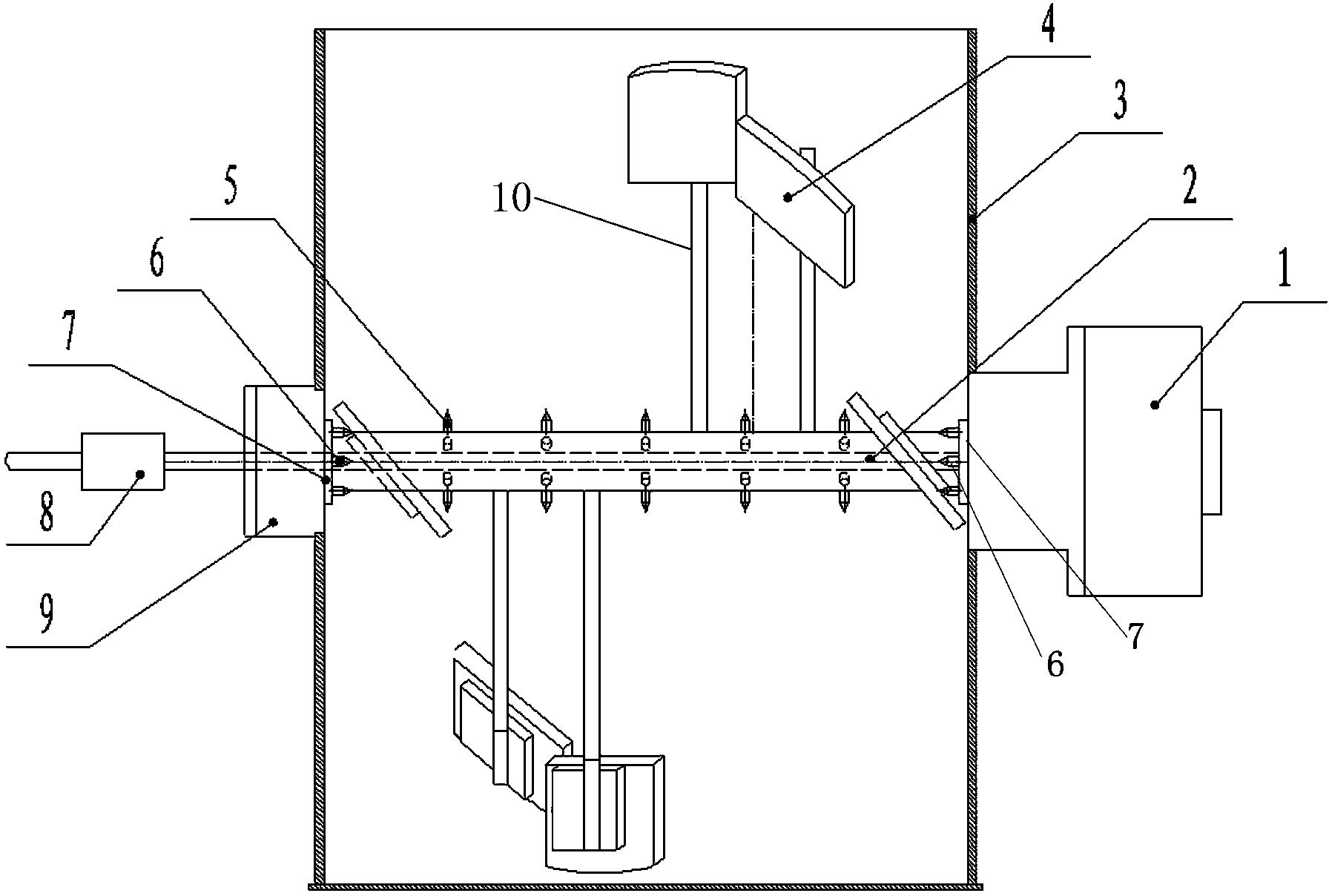

[0014] A wet-type concrete mixer for dust suppression and anti-clogging pipes used in coal mines, including a mixing drum 3 with an upper opening. There is a stirring shaft 2 horizontally supported between the 9; one end of the stirring shaft 2 passes through the shaft end 9, and the part of the stirring shaft 2 located in the mixing drum 3 is fixed with a plurality of stirring blades 4 through a connecting rod 10 perpendicular to the stirring shaft 2 ; The stirring shaft 2 has a hollow structure and an opening is provided at one end passing through the shaft end 9; the position connected to the non-connecting rod 10 on the stirring shaft 2 is provided with multiple groups of dust-reducing nozzle groups in sequence, and each group of dust-reducing nozzle groups includes a plurality of The dust suppression nozzle 5 arranged around the stirring shaft 2 communicates with the inside of the stirring shaft 2 and is perpendicular to the stirring shaft 2 . The opening of the stirri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com