Preparation method of thermoelectric compound

A compound and thermoelectric technology, applied in tin compounds, chemical instruments and methods, lead sulfide, etc., can solve the problems of heavy resource and environmental burden, high power consumption, etc., and achieve the effect of low price, short material cycle, and rapid synthesis of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In this embodiment, the preparation method of the thermoelectric compound of the present invention is described in detail by taking the preparation process of PbS as an example.

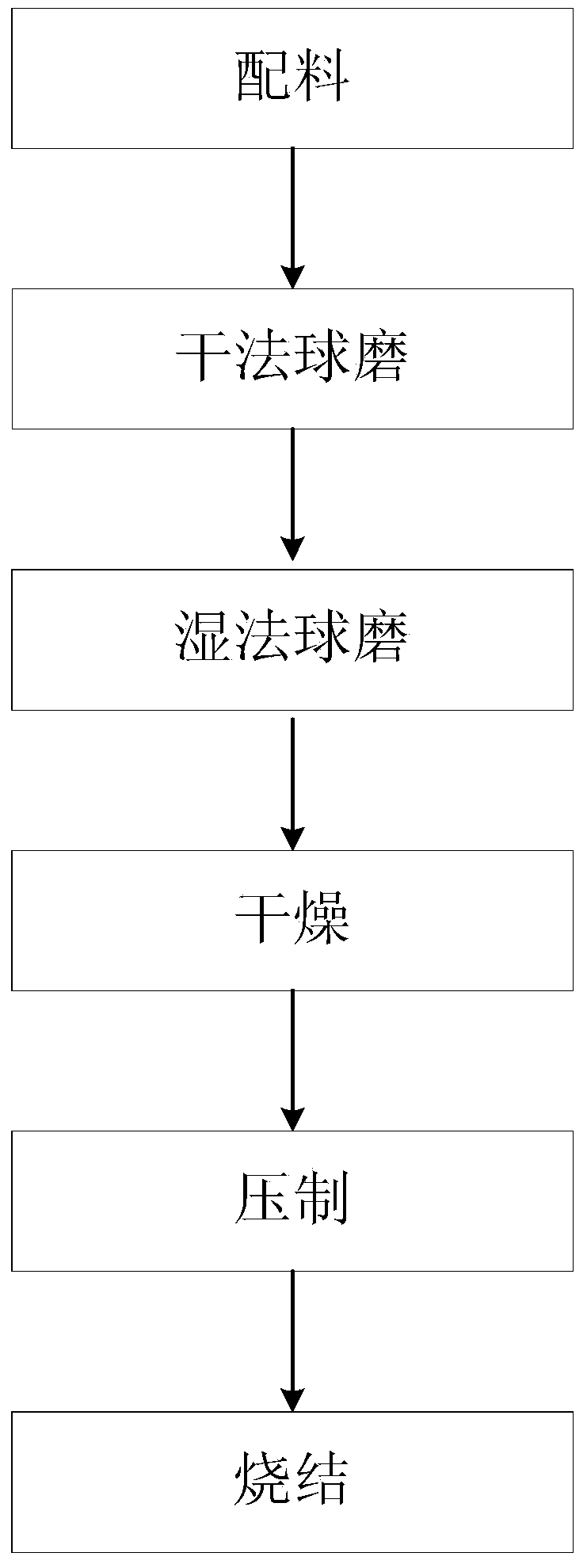

[0029] Such as figure 1 As shown, the method includes the following steps: 1) batching step; 2) dry ball milling step; 3) wet ball milling step; 4) drying step; 5) pressing step; 6) sintering step.

[0030] The above six steps will be described in detail below.

[0031] 1) Ingredients step

[0032] Lead (Pb) powder and sulfur (S) powder are used as the main raw materials, mixed with Pb powder and S powder in a certain molar ratio, and placed in a stainless steel ball mill tank. Preferably, the molar ratio of Pb powder to S powder is 0.8:1.2 to 1.2:0.8, more preferably 1:1. In actual operation, considering the loss of S powder, the molar ratio of Pb powder and S powder can be set to 1:1.03.

[0033] Preferably, high-purity Pb powder (99.9% purity) and S powder (99.99% purity) are used as ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap