Magnesium alloy melt purification method

A melt purification, magnesium alloy technology, applied in the direction of improving process efficiency, etc., can solve the problems of high-efficiency impurity removal, which cannot be achieved at the same time, and achieve the effects of promoting homogenization, reducing production costs, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

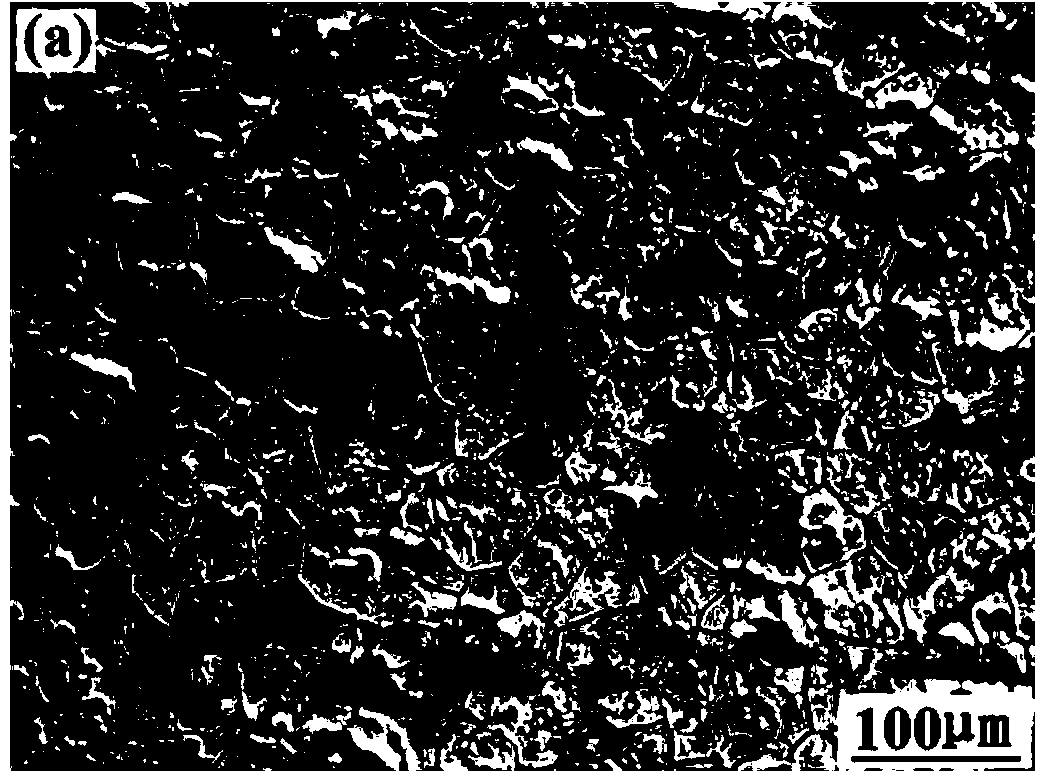

[0031] This embodiment relates to a method for purifying a rare earth magnesium alloy Mg-3Nd-0.2Zn-0.5Zr by gas rotary blowing combined with ceramic foam filtration, which specifically includes the following steps: 6 / CO 2 or SO 2 / CO 2 or CO 2 / Ar or difluoromethane HFC-32 or HFC134a (ie C 2 h 2 f 4 ) Under the protection of gas, melt the Mg-3Nd-0.2Zn-0.5Zr magnesium alloy and heat it up to 720 ° C. Put the conventional blowing device with rotating blades into the magnesium alloy melt to start rotating and pass in argon or nitrogen to blow The hole diameter of the head is 0.1mm, the rotation speed of the rotating blowing rotor is 150 rpm, the blowing flow rate is 2 liters per minute, and the blowing time is 20 minutes; after the blowing is finished, let it stand for 20 minutes, then cool down to 720°C, remove The scum on the surface of the alloy liquid is poured into the sand mold, and a foam ceramic filter is placed at the sprue of the sand mold. The material of the fo...

Embodiment 2

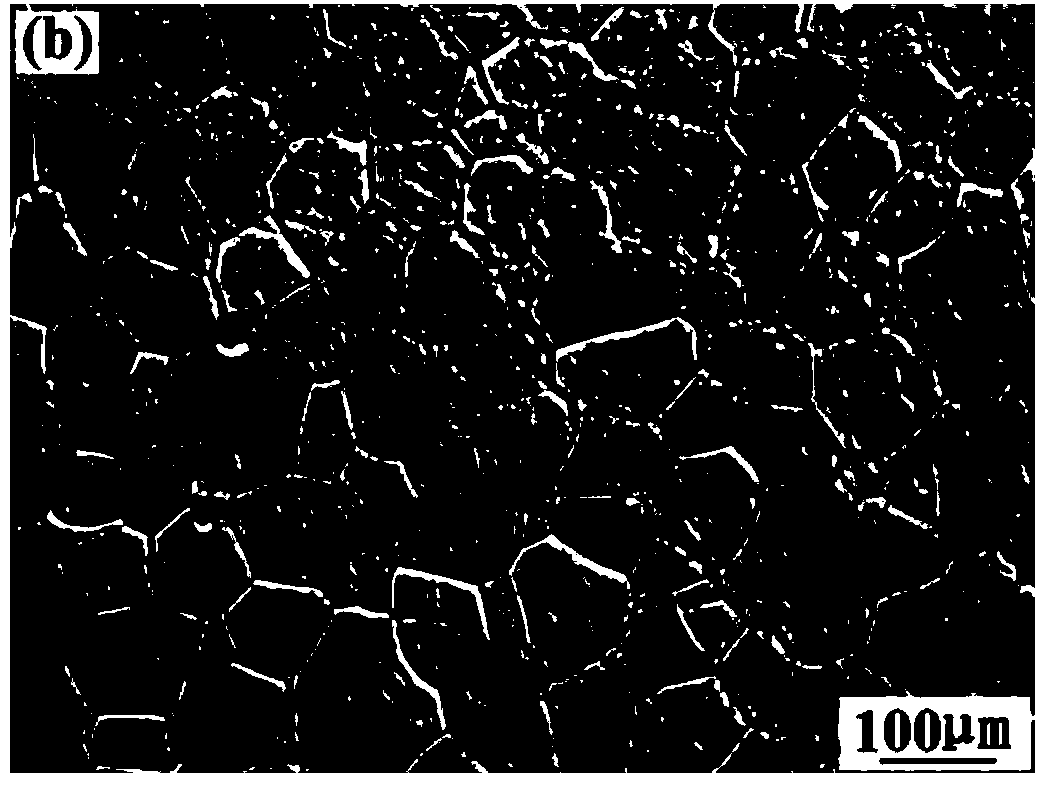

[0035] This embodiment relates to a high-strength heat-resistant rare-earth magnesium alloy Mg-10Gd-3Y-0.5Zr gas rotary injection combined with foam ceramics filtration purification method, which specifically includes the following steps: 6 / CO 2 or SO 2 / CO 2 or CO 2 / Ar or difluoromethane HFC-32 or HFC134a (ie C 2 h 2 f 4 ) Under the protection of gas, melt the Mg-10Gd-3Y-0.5Zr magnesium alloy and heat it up to 740 ° C. Put the conventional blowing device with rotating blades into the magnesium alloy melt and start to rotate and pass in argon or nitrogen. The hole diameter is 0.2mm, the rotational speed of the rotating blowing rotor is 100 rpm, the blowing flow rate is 1 liter / min, and the blowing time is 20 minutes; after the blowing is finished, let it stand for 20 minutes, then cool down to 720°C, and remove the alloy The scum on the surface of the liquid is poured into the sand mold, and the foam ceramic filter is placed at the gate of the sand mold sprue. The mate...

Embodiment 3

[0039] This embodiment relates to a traditional commercial magnesium alloy ZK60 gas rotary injection combined with foam ceramics filtration and purification method, which specifically includes the following steps: 6 / CO 2 or SO 2 / CO 2 or CO 2 / Ar or difluoromethane HFC-32 or HFC134a (ie C 2 h 2 f 4 ) Under the protection of gas, melt the ZK60 magnesium alloy and heat it up to 720°C. Put the conventional blowing device with rotating blades into the magnesium alloy melt and start to rotate and feed argon or nitrogen gas. The hole diameter of the blowing head is 0.2mm. The rotor speed is 200 rpm, the air blowing flow rate is 2.5 liters / min, and the gas injection time is 10 minutes; after the injection is completed, let it stand for 20 minutes and keep it warm for 20 minutes, then cool down to 700°C, remove the scum on the surface of the alloy liquid, and then cast In the sand mold, a ceramic foam filter is placed at the gate of the sand mold sprue. The material of the cera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com