Circular erosion test device for closed pipelines and using method of circular erosion test device

A test device and pipeline device technology, applied in the direction of measuring devices, testing wear resistance, weather resistance/light resistance/corrosion resistance, etc., can solve problems such as pressure, temperature, flow rate simulation, etc., to achieve the effect of ensuring accuracy and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the drawings and embodiments.

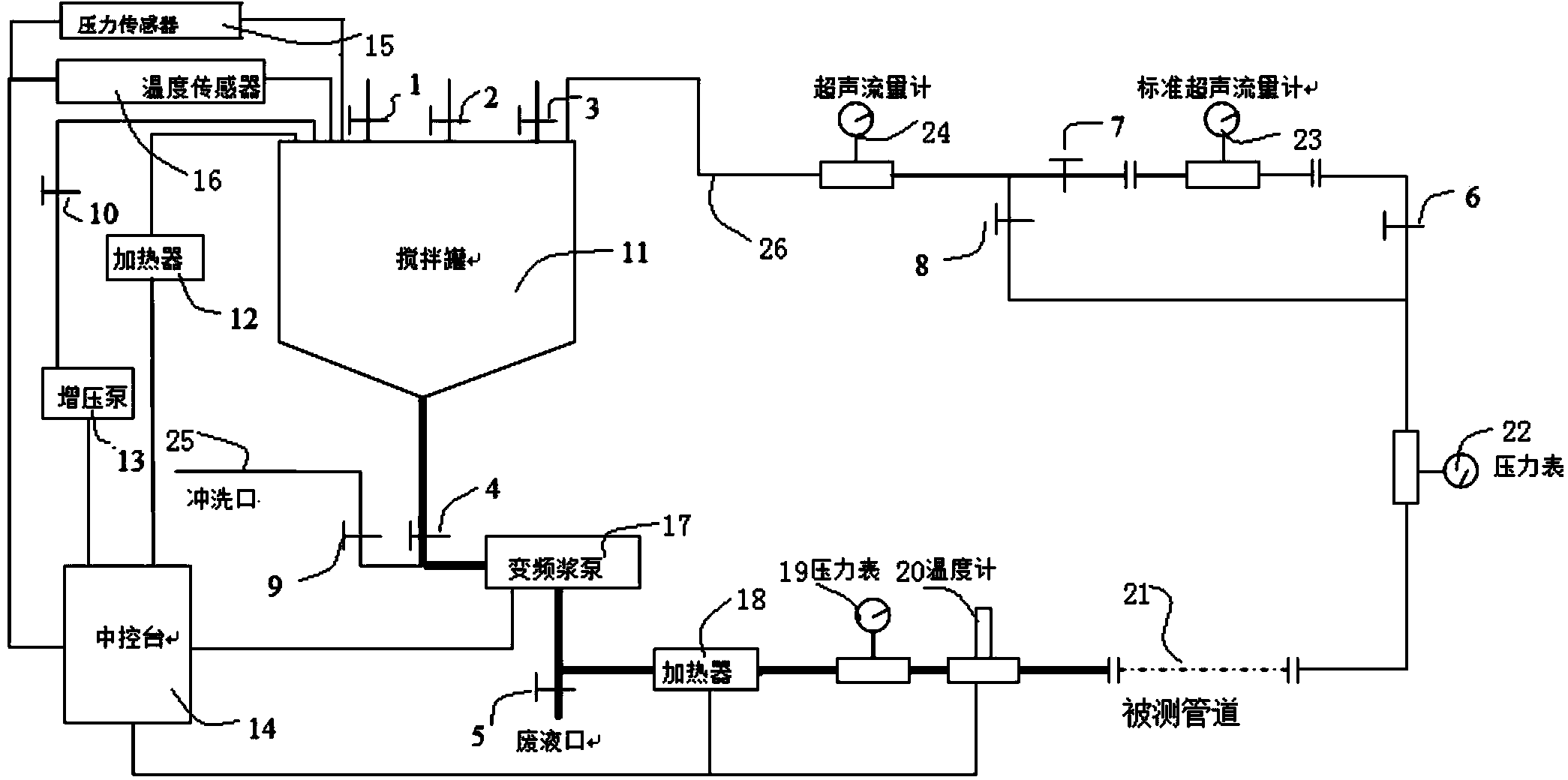

[0031] Such as figure 1 As shown, a closed pipeline cyclic erosion test device includes a stirring device, a measuring device, a control device, a calibration device, and a pipeline device. The medium is stirred in the stirring device, and then measured through the pipeline device to the measuring device. The device is connected with the control device, the control device collects data and adjusts the results measured by the measuring device, and the calibration device is connected with the measuring device and performs calibration;

[0032] The pipeline device includes a stainless steel pipeline 26 and a tested pipeline 21, and the tested pipeline 21 is a replaceable pipeline;

[0033] The control device is a center console 14, which includes a data acquisition module, a temperature control module, and a pressure control module;

[0034] The stirring device includes a sti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com