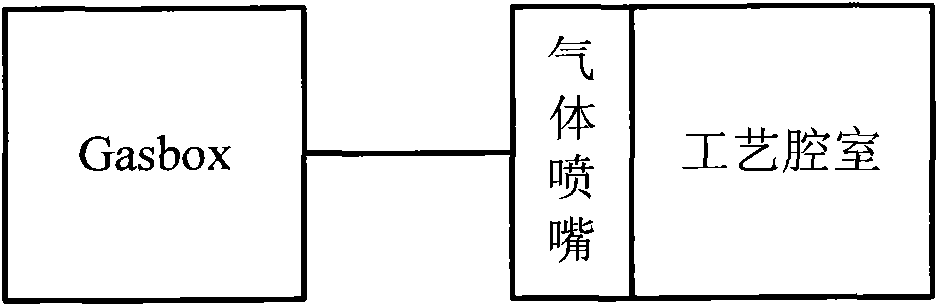

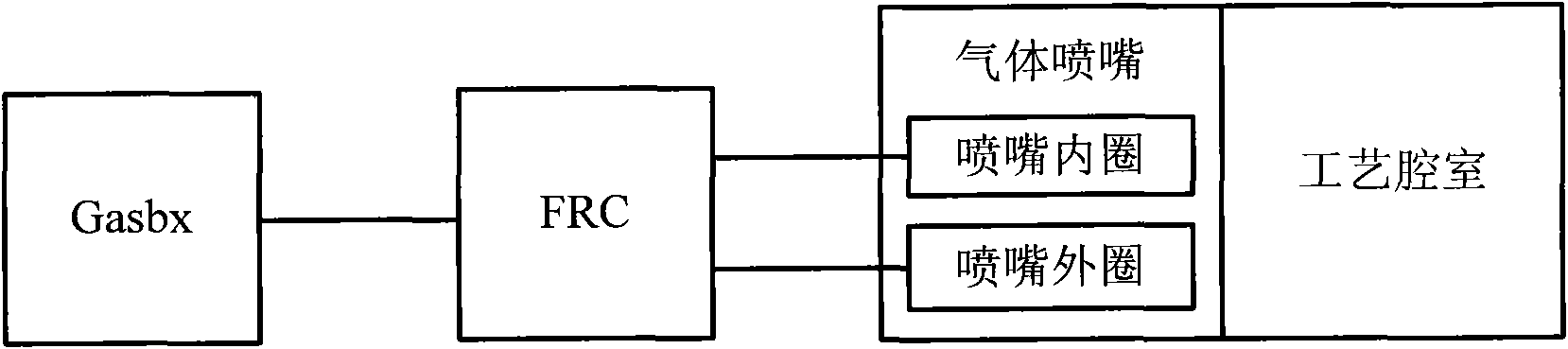

On-line calibrating method for FRC (Flow Ratio Controller), system and plasma treatment equipment

A proportional controller and calibration method technology, applied in the field of microelectronics, can solve problems affecting process stability and uniformity, reduce product quality, FRC calibration, etc., to avoid process stability decline, reduce time spent, and eliminate equipment failures Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

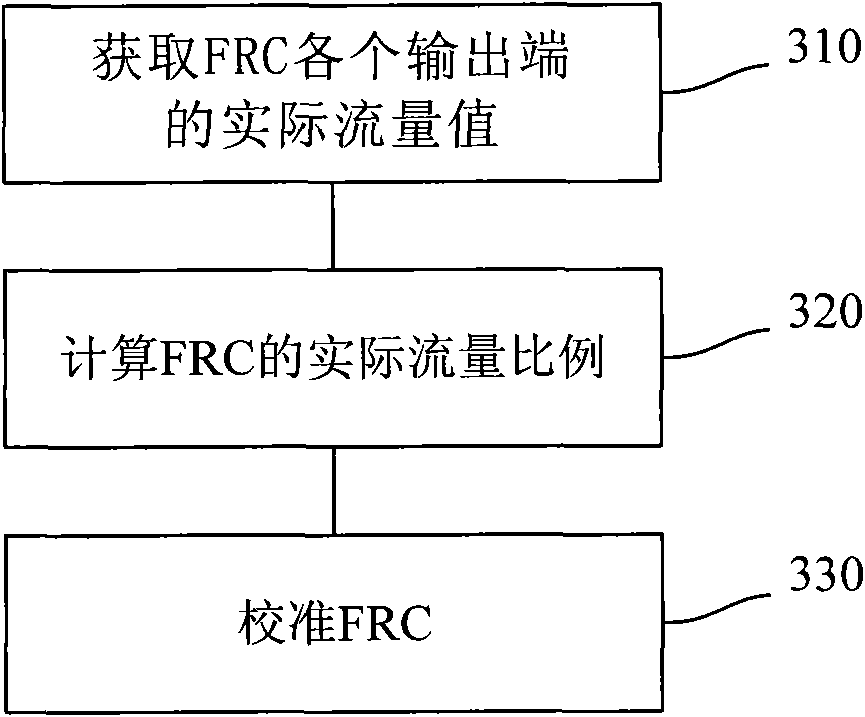

[0038] In order for those skilled in the art to better understand the technical solution of the present invention, the FRC online calibration method, system and plasma processing equipment provided by the present invention will be described in detail below with reference to the accompanying drawings.

[0039] The FRC online calibration method provided by the present invention is used to calibrate the actual output ratio of each output terminal of the FRC. The FRC has an input terminal and multiple (at least two) output terminals, and its function is to distribute the gas from its input terminal to each output terminal according to a preset ratio. see image 3 , the method comprises the following steps: 1) obtaining the actual flow value of each output end of the FRC; 2) calculating the actual output ratio of the FRC according to the actual flow value of each output end; 3) performing the FRC according to the preset ratio and the actual output ratio calibration.

[0040] Wher...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com