Vibration generating apparatus

A technology of vibration power generation and induction current, applied in the direction of electromechanical devices, electrical components, etc., can solve the problems of complex structure, difficult implementation, unsatisfactory effect, etc., and achieve the effect of no power generation cost, simple structure, convenient conversion and networking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

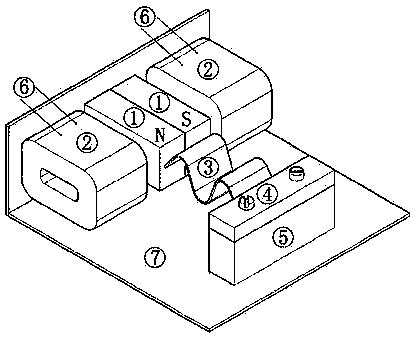

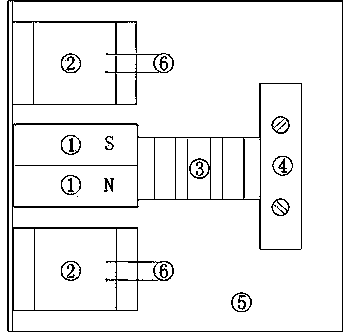

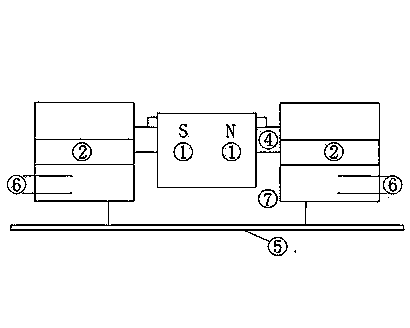

[0013] exist figure 1 In the shown embodiment, the generator coil (2) and bracket (7) are installed on the base (5), the permanent magnet (1) is fixed on the front end of the corrugated spring plate (3), and the corrugated spring plate (3) The rear end of the motor is fixed on the bracket (7) through the fixed pressure plate (4). The permanent magnet (1) relies on its own weight inertia to perform amplified or decelerated oscillations under the vibration of the vibration source, and the permanent magnet (1) performs oscillating motion. At the same time, the generator coils located at both ends of the magnetic poles are continuously cut through the magnetic field lines of the north and south stages, so that the generator coils induce alternating positive and negative alternating voltage currents, and the voltage currents are output through the generator coil lead wires (6);

[0014] exist figure 2 In the front sectional view shown, the two generator coils (2) fixed on the bas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com