Rotary variable capacitive generator

A variable capacitance and rotary technology, applied in induction generators and other directions, can solve the problems of small power/weight ratio, low conversion efficiency, and large heat generation, achieving high power/weight ratio, less use, and less heat generation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

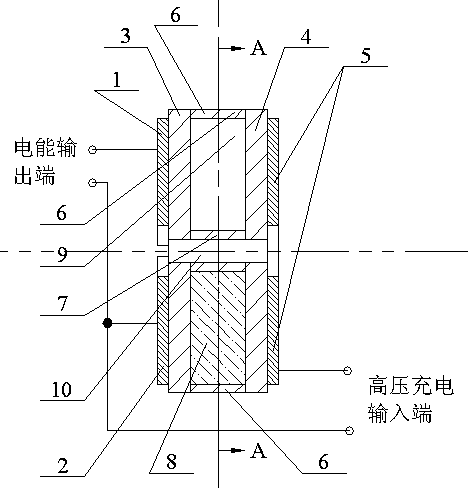

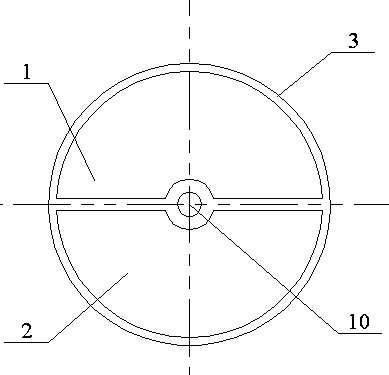

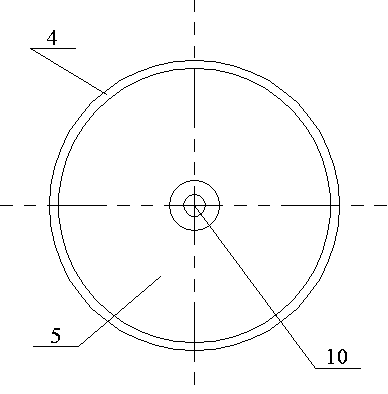

[0008] Specific embodiment one: combination figure 1 , figure 2 , image 3 , Figure 4 To describe this embodiment, this embodiment consists of a first semicircular conductive metal sheet 1, a second semicircular conductive metal sheet 2, a first dielectric disc 3, a second dielectric disc 4, a conductive metal disc 5, a large sealing ring 6, Small sealing ring 7, conductive liquid 8, inert gas 9;

[0009] One end surface of the first semicircular conductive metal sheet 1 and one end surface of the second semicircular conductive metal sheet 2 are both connected to one end surface of the first dielectric disc 3, and the first semicircular conductive metal sheet 1 is opposite to the second semicircular conductive metal sheet 2 A complete circle is formed and insulated from each other; one end face of the conductive metal disc 5 is connected to one end face of the second dielectric disc 4; the other end face of the first dielectric disc 3 passes through the large seal ring 6 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com