Method for assembling gearbox components

A technology for connecting components and motor vehicle transmissions, applied to components with teeth, belts/chains/gears, mechanical equipment, etc., can solve the problems of reducing vibration and insufficient, and achieve the effect of high shifting force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

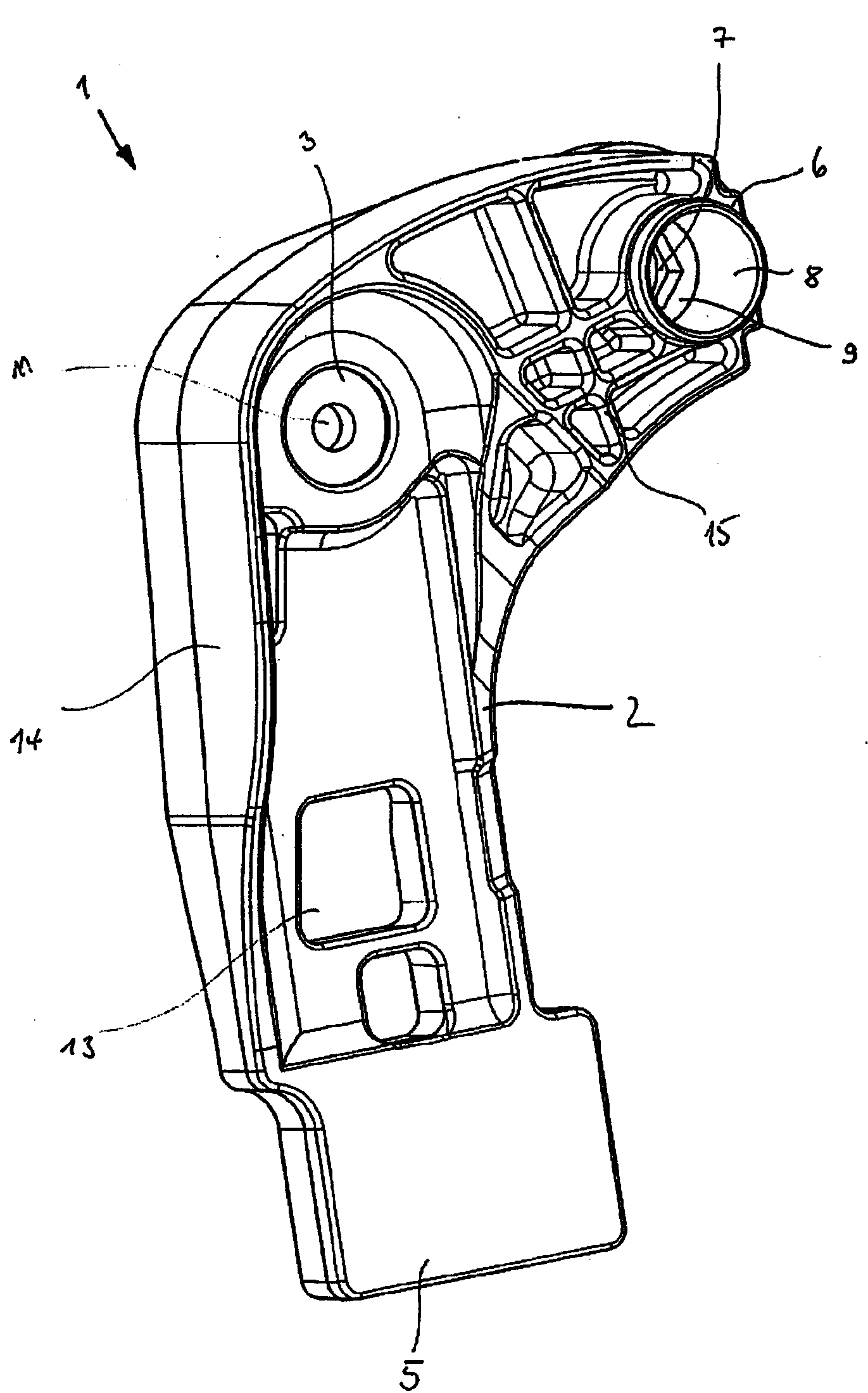

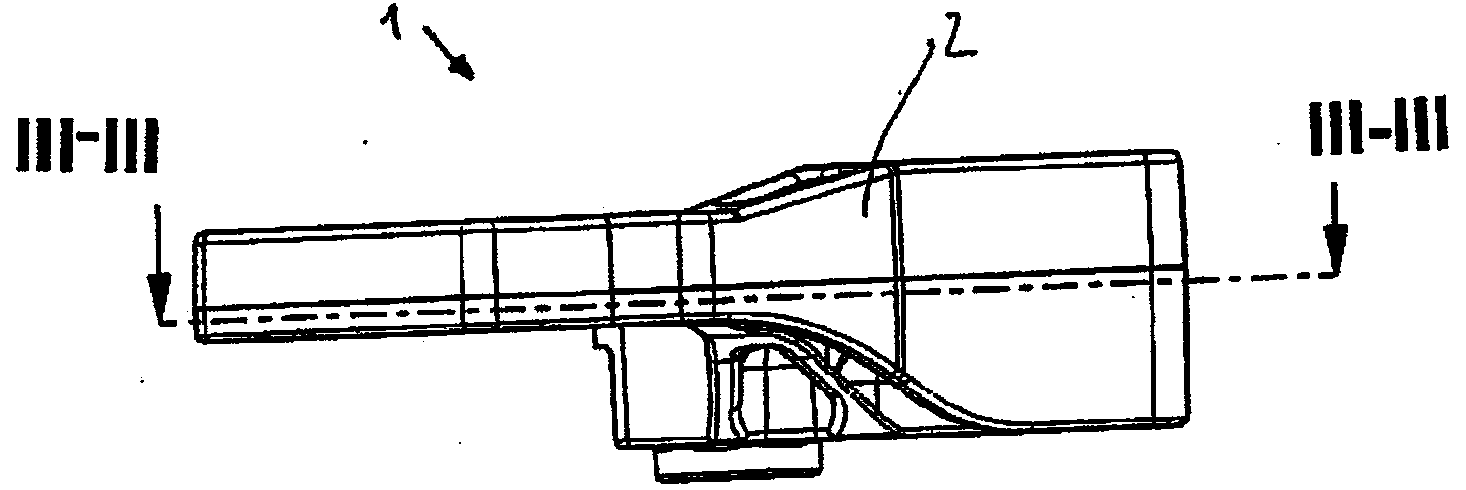

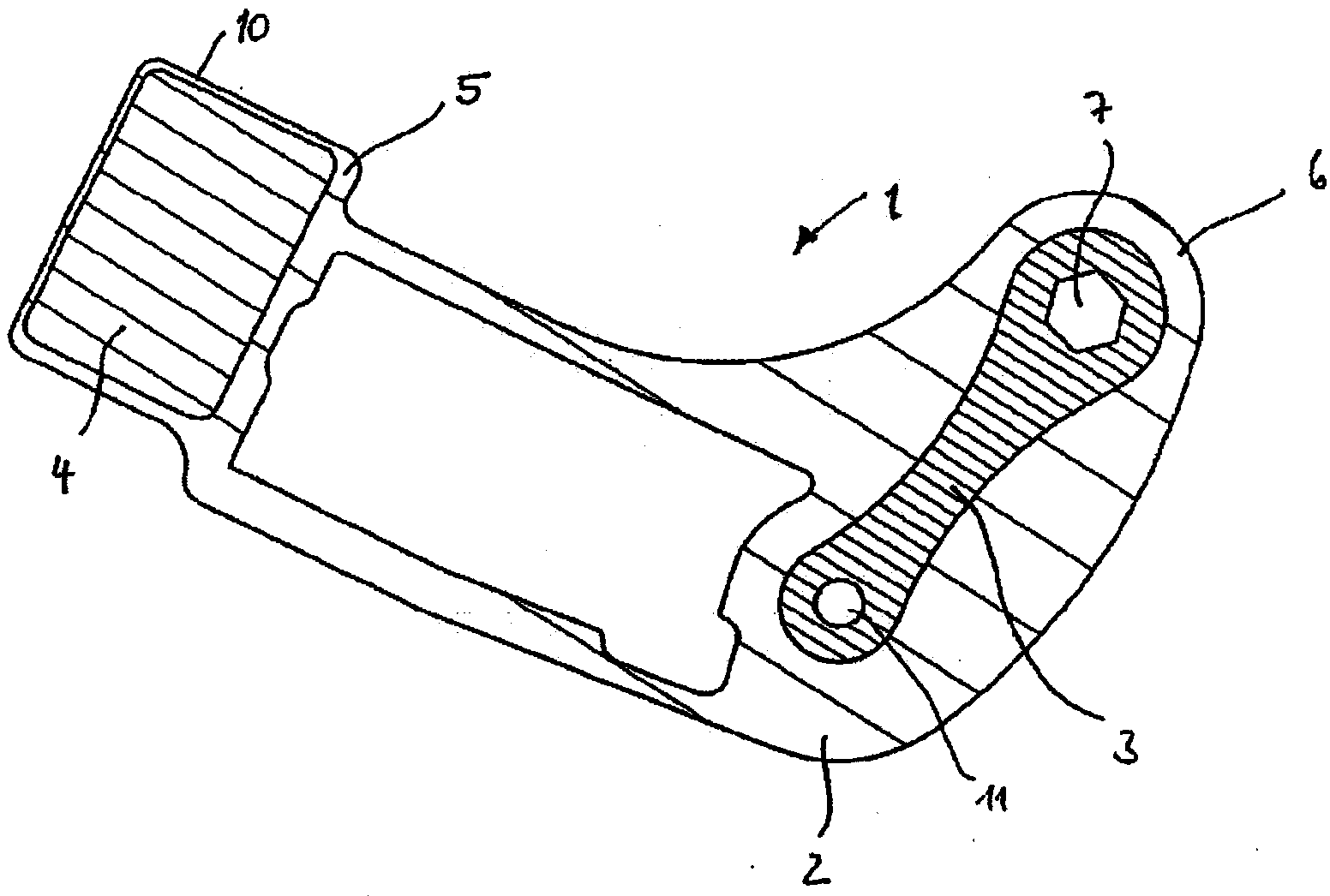

[0031] Figures 1 to 3 A rotating mass 1 for a shift shaft (not shown) of a motor vehicle gear transmission is shown. as from image 3 It can be seen that the rotating mass 1 consists of three individual parts which are fixedly connected to one another: the rotating mass has a boom 2 , a connecting part 3 and a shifting mass 4 , wherein the individual parts 2 , 3 , 4 each consist of different materials.

[0032] The revolving mass 1 has an angular basic shape with two legs, on one leg end 5 of which a shifting mass 4 is arranged and on the other leg end 6 of which a coupling Affiliated institutions7. The coupling mechanism 7 is formed by a generally hexagonal shaped cutout in the connecting piece 3 ( Figure 4). For better guidance of the shifting shaft, the part of the connecting part 3 surrounding the cutout forms a cylindrical head as base 9 and the sleeve 8 connected thereto. Due to the non-circular recess, the pivoting mass 1 can be positioned in a form-fitting and r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com