Optical semiconductor element, its control method and its manufacturing method

A technology of optical semiconductor components and control methods, applied in optical components, light guides, optics, etc., can solve problems such as difficulty in achieving stable control, compromise between wavelength bandwidth and modulation efficiency, and narrowing of wavelength bandwidth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach )

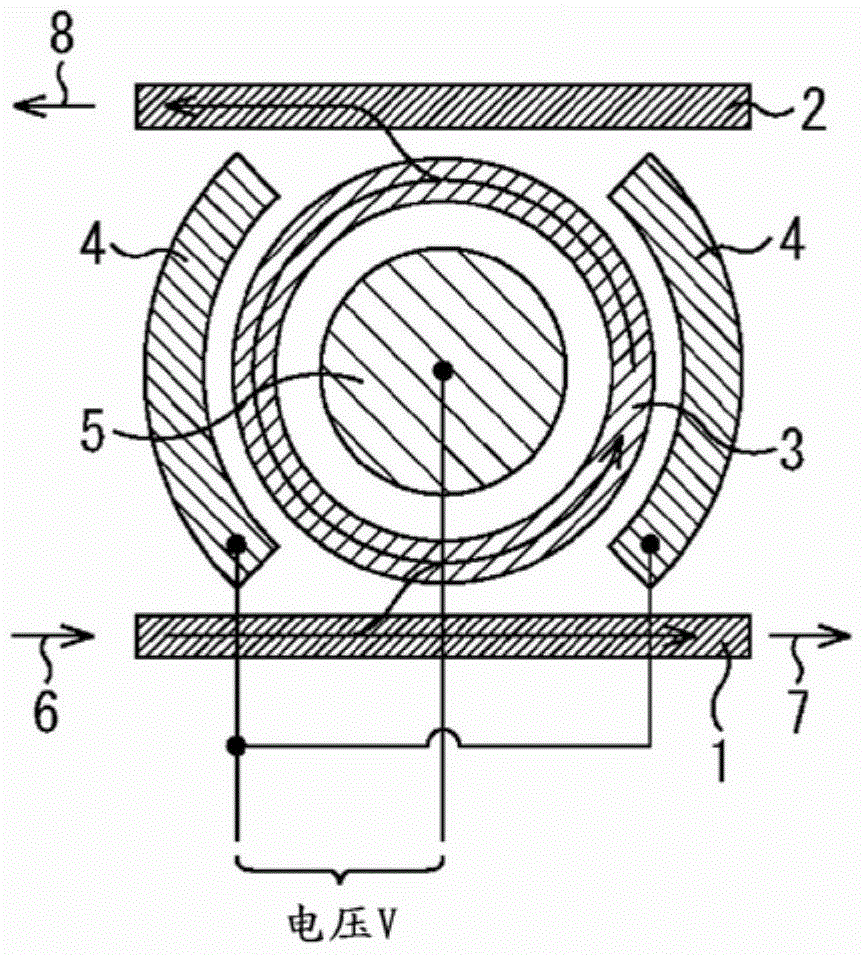

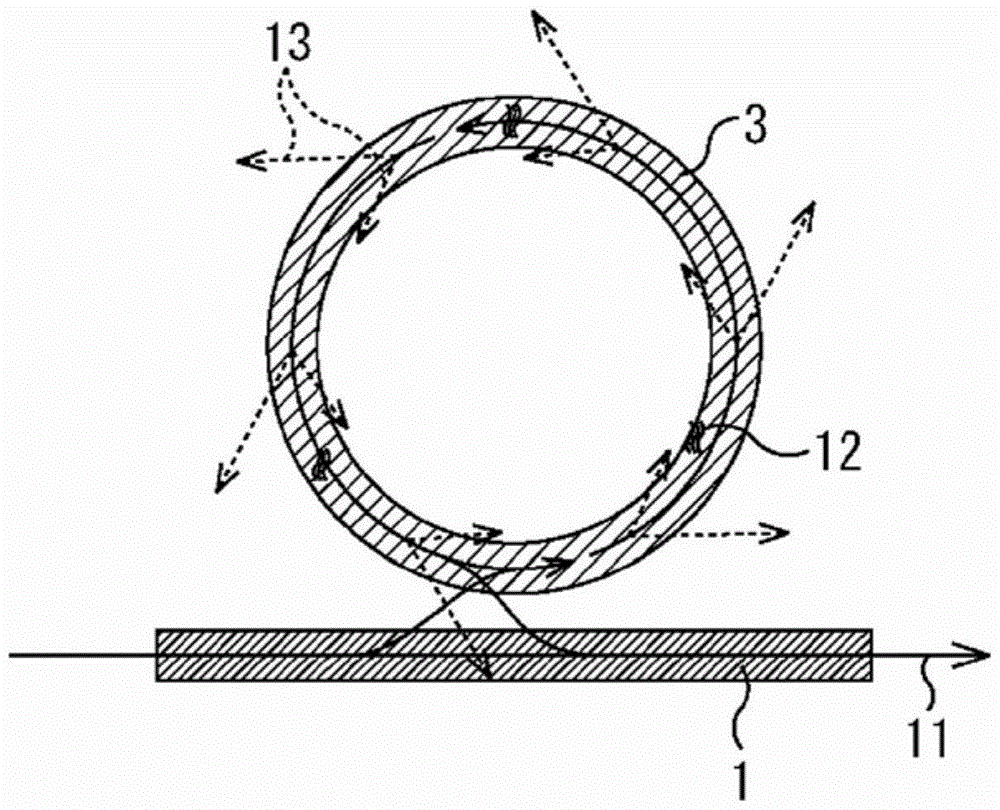

[0063] First, the first embodiment will be described. Figure 1A is a diagram showing an example of a ring modulator. This ring modulator includes two linear waveguides 1 and 2 and a ring waveguide 3 provided therebetween. In addition, the modulation electrode 4 is provided outside the ring waveguide 3 , and the modulation electrode 5 is provided inside the ring waveguide 3 .

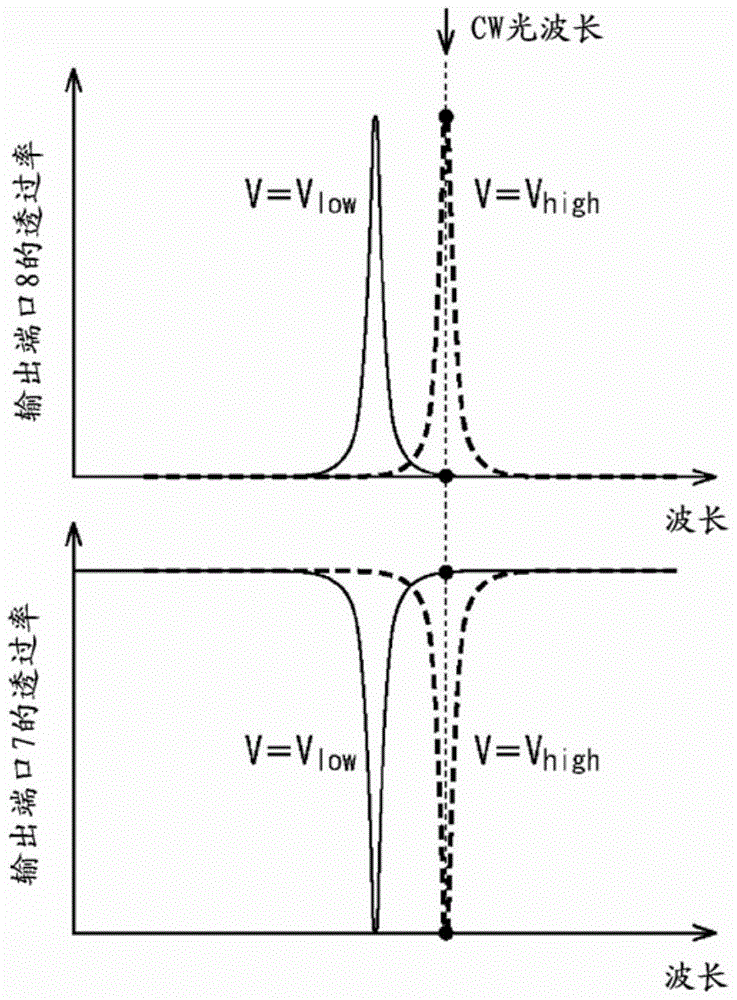

[0064] Furthermore, when the CW light incident on the input port 6 of the waveguide 1 coincides with the wavelength of the CW light at the ring resonance wavelength (an integer fraction of the optical path length of the circular waveguide 3) determined by the optical path length of the optical revolution of the ring waveguide 3, is introduced into the output port 8 of the waveguide 2 . On the other hand, when the ring resonance wavelength does not match the wavelength of the CW light, it is introduced into the output port 7 of the waveguide 1 . In addition, when the modulation voltage V applied to the...

no. 2 Embodiment approach )

[0075] Next, a second embodiment will be described. Figure 10A is a diagram showing the layout of the optical semiconductor element according to the second embodiment, Figure 10B is along Figure 10A A cross-sectional view of the line I-II, Figure 10C is along Figure 10A Sectional view of line III-II.

[0076] In the second embodiment, if Figure 10B as well as Figure 10C As shown, SiO is formed on the Si substrate 101 2 Film 102. And, if Figure 10A ~ Figure 10C shown in SiO 2 On membrane 102, the annular n + layer 105n, n - layer 104n, p - Layer 104p and p + The layers 105p are arranged in this order from the inner side and formed. in n + layer 105n, n - layer 104n,p - Layer 104p and p + The layer 105p uses, for example, Si doped with impurities. Additionally, covering n + layer 105n, n - layer 104n, p - Layer 104p and p + SiO of layer 105p 2 film 106 formed on SiO 2 film 102, the SiO 2 film 106 and n - layer 104n and p - A ring-shaped heater 10...

no. 3 Embodiment approach )

[0084] Next, a third embodiment will be described. Figure 11A is a diagram showing the layout of the optical semiconductor element according to the third embodiment, Figure 11B is along Figure 11A A cross-sectional view of the line I-II, Figure 11C is along Figure 11A Sectional view of line III-II.

[0085] In the third embodiment, if Figure 11A ~ Figure 11C shown, in n + The inner side of the layer 105n is provided with a ring-shaped light absorbing material 114b, and the inner side is also provided with a groove 115. Other configurations are the same as those of the second embodiment.

[0086] In such a third embodiment, absorption of light 131 and heat generation 132 also occur in the light-absorbing material 114b. Therefore, heat can be used more efficiently than in the second embodiment.

[0087] In addition, if the light-absorbing material 114b is provided, the light-absorbing material 114a may not be provided.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com