Antifouling device of coating machine

A spraying machine and anti-fouling technology, which is applied to the device and coating of the surface coating liquid, can solve the problems of ingenious structural design of the induction device, shorten the service life of the induction device, and cannot guarantee the spraying effect, etc., to achieve Anti-fouling effect, favorable for widespread application, and ingenious structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

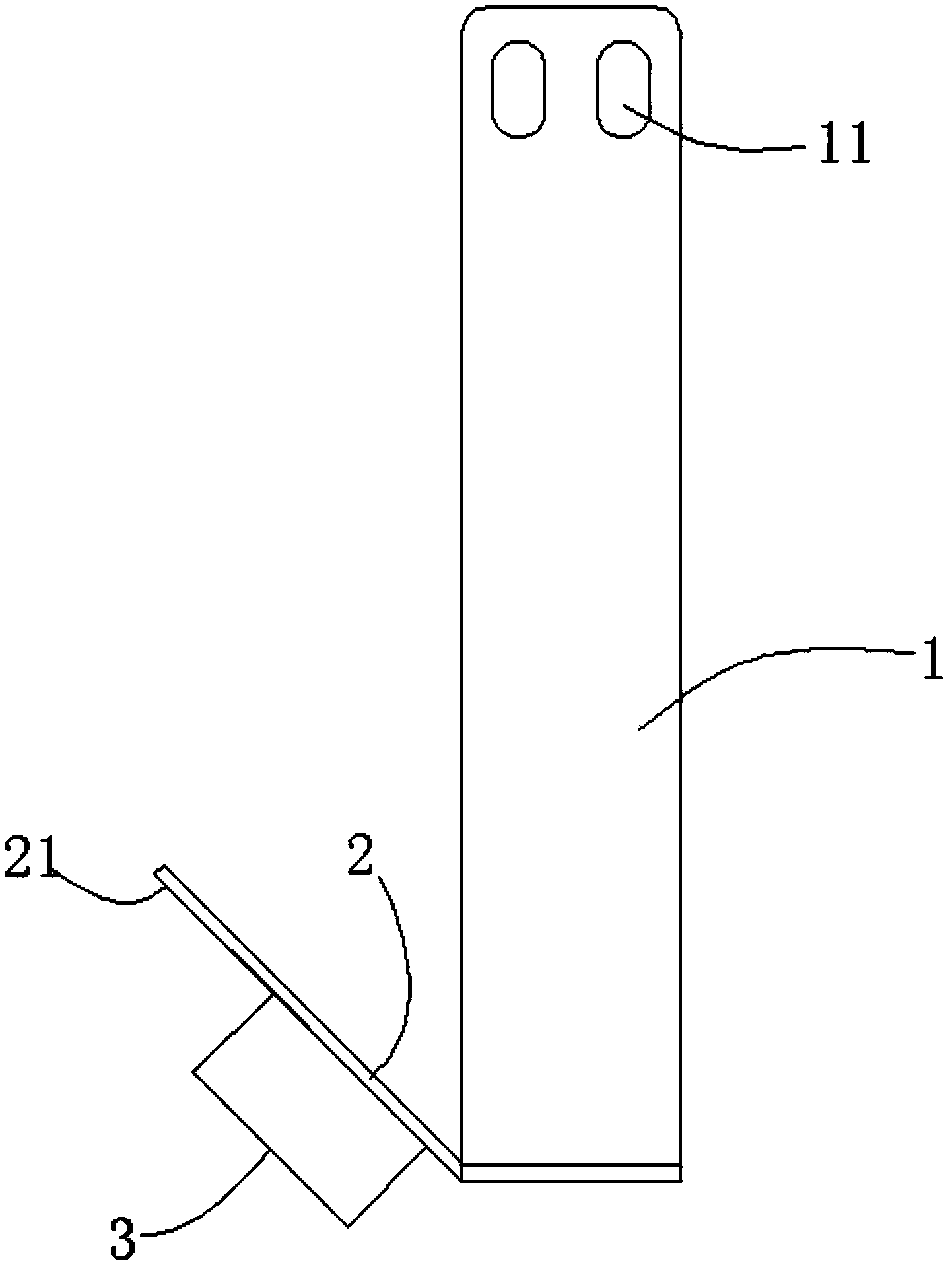

[0012] Examples, see figure 1 , an antifouling device for a spraying machine provided in this embodiment, which includes a mounting base 1, an inclined baffle 2 and a photoelectric sensor 3, the photoelectric sensor 3 is arranged in the middle of the inclined baffle 2, and the inclined baffle The tail end of 2 is arranged on the bottom of the mounting bracket 1, and the top is inclined to the side of the photoelectric sensor 3, and extends until the photoelectric sensor 3 can slightly protrude in the vertical direction to form a dirt-repelling portion 21.

[0013] In this embodiment, the installation support 1 and the inclined baffle plate 2 are formed by integral stamping and bending of a metal plate. The process is simple and easy to implement. In other embodiments, the installation support 1 and the inclined baffle 2 can be formed in a split structure according to the requirements of the production process.

[0014] At least one installation hole 11 is provided on the top...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com