Drawing die for efficient heat dissipation copper tube

A heat-dissipating copper tube and mold technology, applied in manufacturing tools, forming tools, metal processing equipment, etc., can solve the problems of limited increase in heat exchange area, affecting heat dissipation performance, inability to make efficient heat-dissipating copper tubes, etc., to increase the internal and external surface area. , the effect of improving the heat dissipation capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

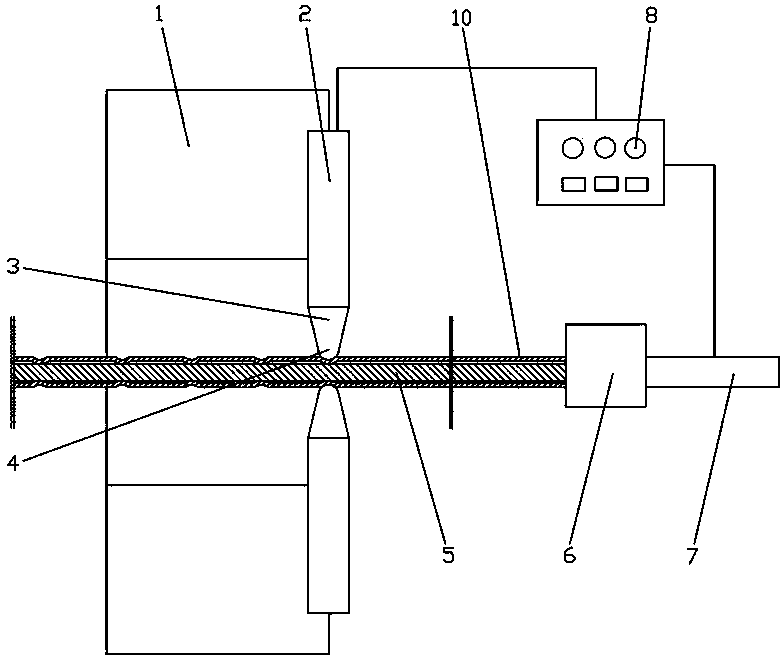

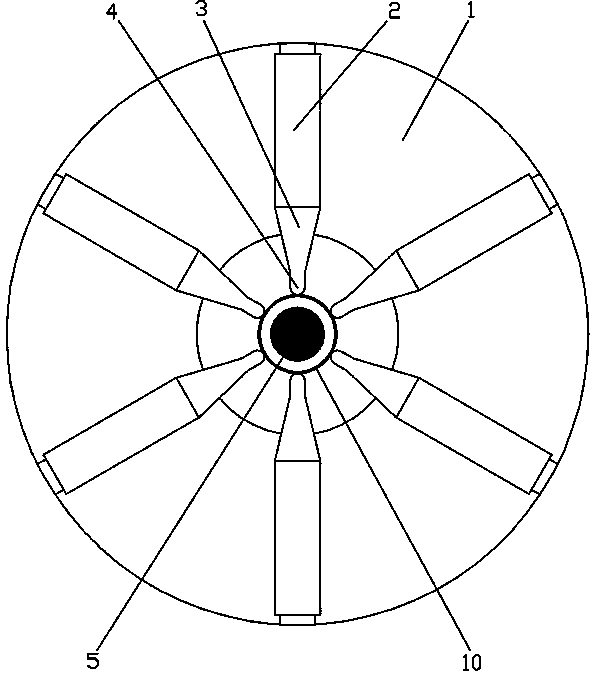

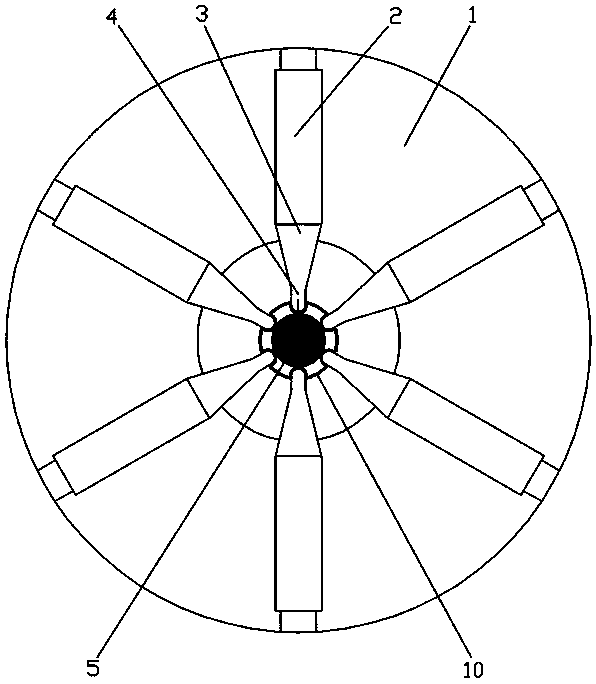

[0014] Such as figure 1 As shown, the present invention discloses a high-efficiency heat dissipation copper pipe drawing die, which includes a chuck 1 and a mandrel 5, and the mandrel 5 is placed in the central hole of the chuck 1, and the mandrel 5 of the chuck 1 Several jaws 2 are connected to the front, and the jaws 2 can move forward and backward to the center of the chuck 1 at the same time. The heads of the jaws 2 each have a pressing die 3, and the ends of the pressing dies 3 are Die head 4.

[0015] In specific operations, such as figure 2 As shown, first insert the mandrel 5 into the embryonic copper tube 10, adjust the position of the claw 2, make the die head 4 and the outer wall of the embryonic copper tube 10, and then open the chuck 1, so that the chuck 1 rotates at a constant speed, and at the same time , drive the claw 2 to move to the center of the chuck 1, drive the pressing die 3 to move to the center of the chuck 1 at the same time, the die head 4 squeez...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com