Heat exchanger

A heat exchanger and flat tube technology, applied in the field of heat exchangers, can solve problems such as low heat exchange efficiency, and achieve the effect of improving heat exchange efficiency and heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

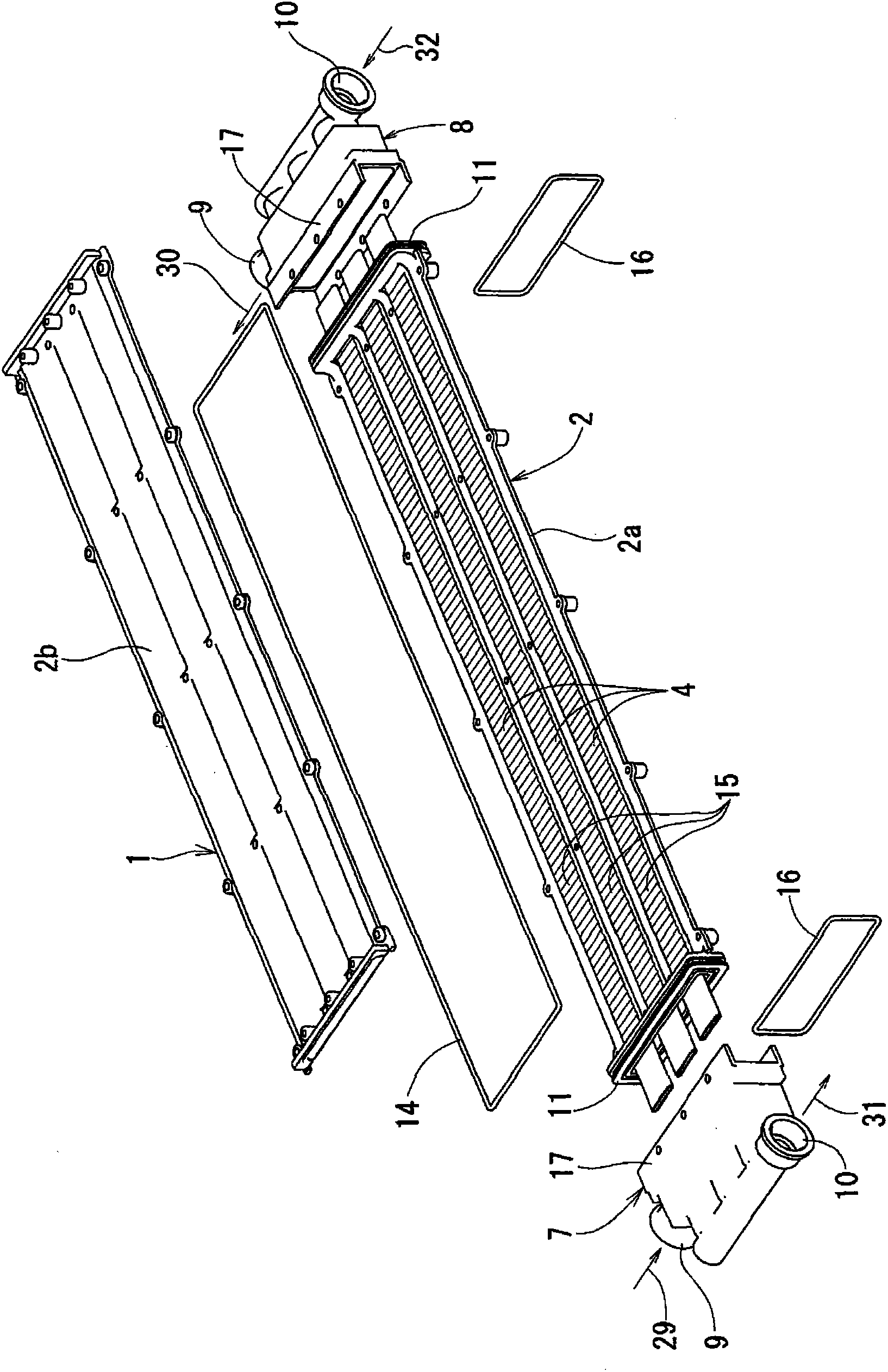

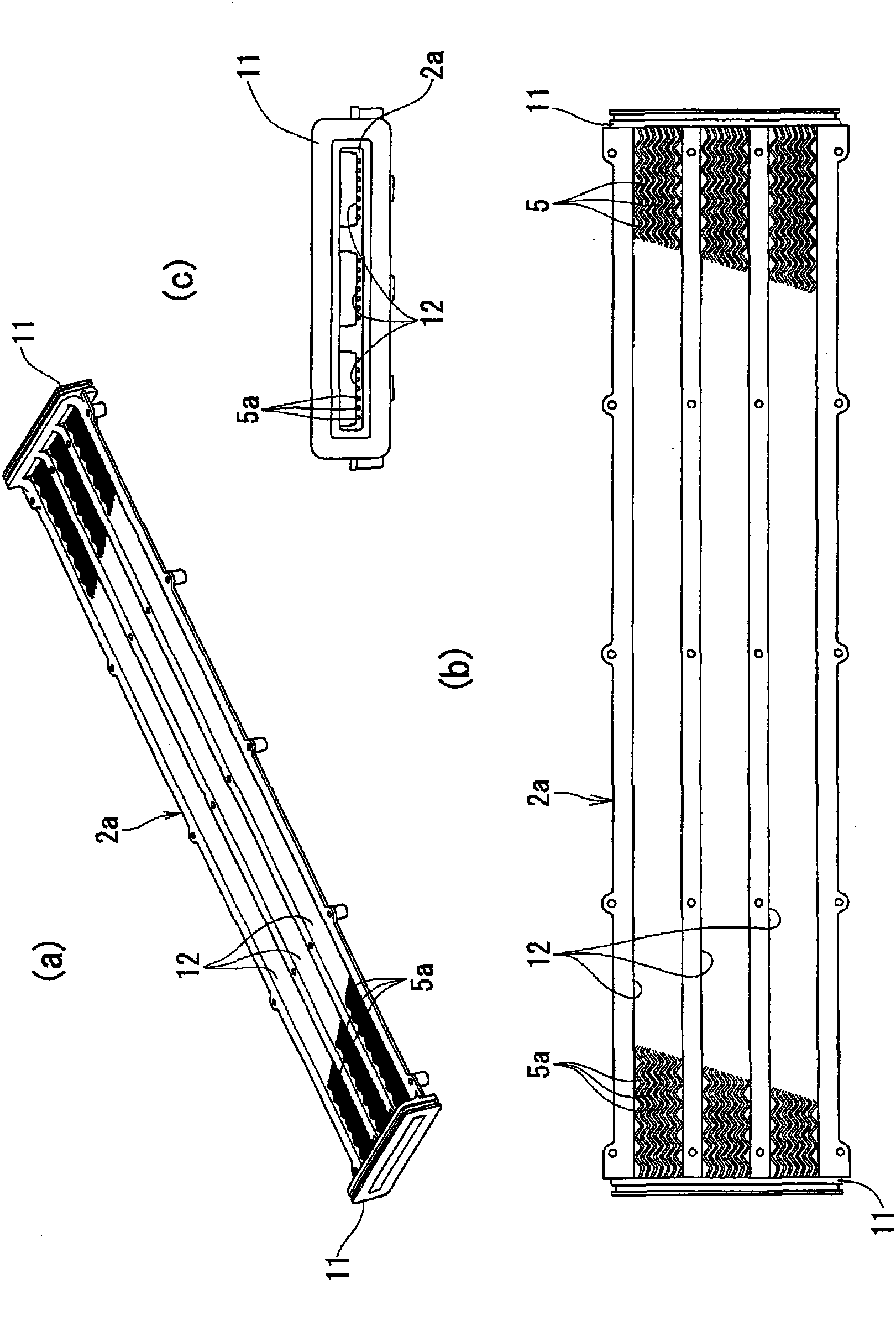

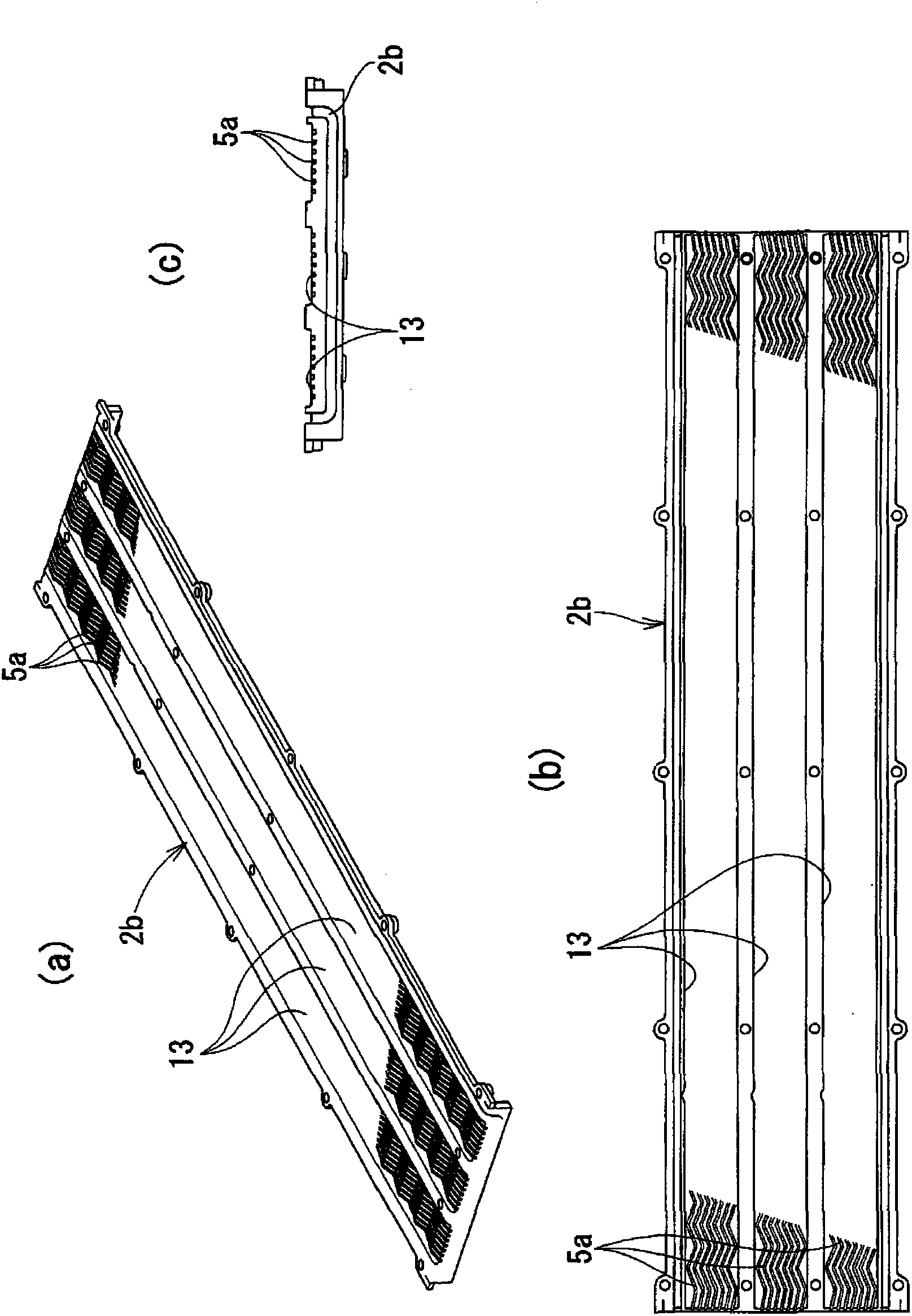

[0029] Hereinafter, embodiments of the present invention will be described with reference to examples in the drawings.

[0030] Figure 1 to Figure 6 Showing the first embodiment of the heat exchanger according to the present invention, the heat exchanger 1 forms three tubes penetrating the entire length of the outer case 2 in a parallel arrangement inside the flat and long outer case 2 . The flat tubes 4 are housed in each of the cylindrical housing parts 3. On the inner peripheral surface of the cylindrical housing part 3, there is formed a channel for allowing one of the fluids intended to exchange heat to flow along the flat tubes 4. The fluid passage 5 that flows in the longitudinal direction, and the inside of the flat tube 4 become the flow passage 6 through which the other fluid flows.

[0031] The fluid supply and discharge heads 7 and 8 are watertightly fixed to both ends of the outer casing 2, and the supply and discharge channels 9 of one side of the fluid supply ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com