Structure of water-cooling channel of casting mold

A water-cooling channel and casting mold technology, applied in manufacturing tools, casting molding equipment, casting molds, etc., can solve the problems of severe reaction, low cooling effect, mold erosion, etc., to increase heat exchange area, enhance cooling efficiency, ensure The effect of die strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

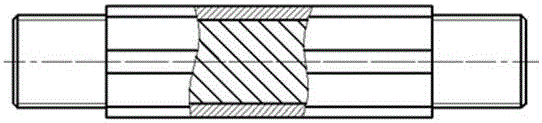

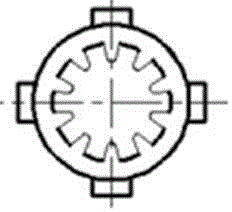

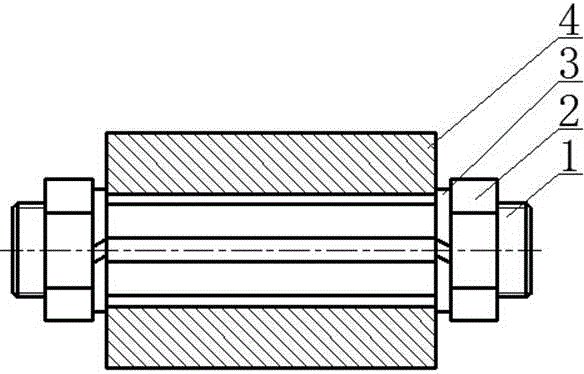

[0021] Such as Figure 1 to Figure 4 As shown, the structure of the water-cooling channel of a casting mold includes a number of internally threaded water-cooled copper tubes 1 embedded in the mounting holes of the mold 4, and the two ends of the internally threaded water-cooled copper tubes 1 are provided with external threads. The thread fixes the internally threaded water-cooled copper tube 1 axially on the mold 4 through the spring washer 3 and the fixing nut 3 (see image 3 ), the outer peripheral wall of the internally threaded water-cooled copper pipe 1 is provided with a spline-shaped multi-tooth structure along the length direction, and a threaded structure is provided in the inner hole (see figure 1 and figure 2 ), a number of s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com