Preparation method of easy-to-dry porous ABS grafted polymer particles

A polymer particle and drying technology, applied in the field of ABS graft polymer preparation, can solve the problem of reducing the transfer time of heat to the inside of the particles, and achieve the effects of reducing uneven drying, increasing internal and external surface areas, and reducing transfer time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

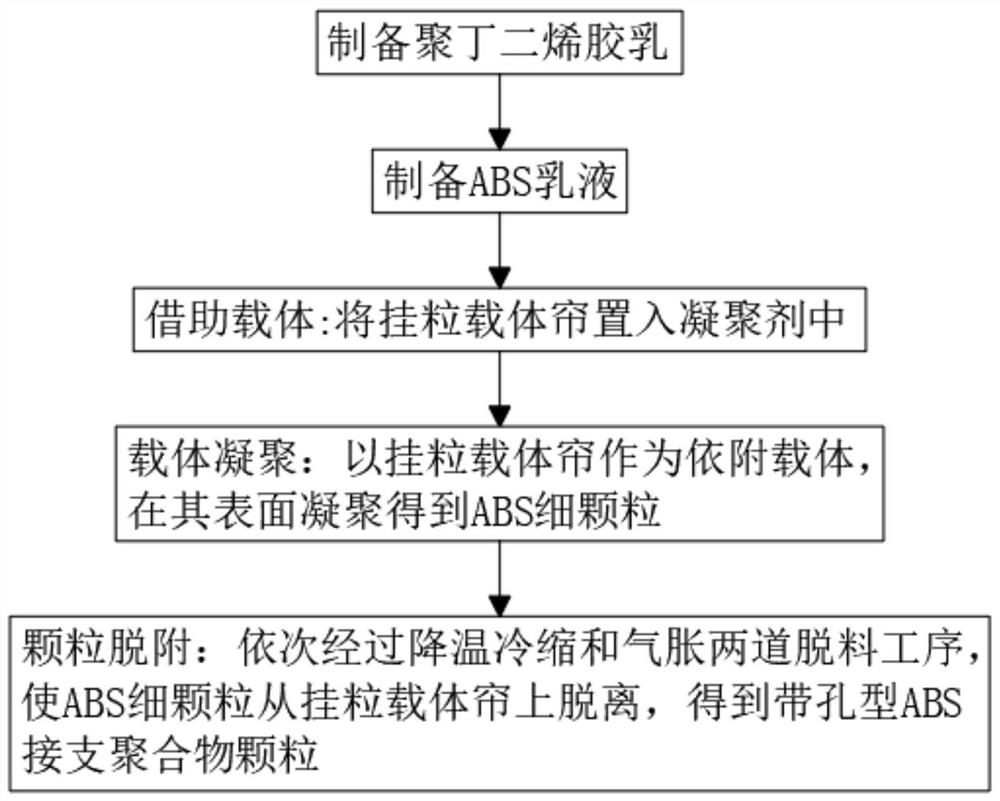

[0052] see figure 1 , a kind of preparation method of easy-to-dry band type ABS graft polymer particle, comprises the following steps:

[0053] S1. Preparation of polybutadiene latex: add an auxiliary agent solution composed of emulsifier, mercaptan, potassium persulfate, etc., together with butadiene, into the polymerization kettle, the reaction temperature is 90°C-93°C, cool with liquid ammonia, and The reacted latex is sent to the degassing tank for processing and aged for 3-4 days;

[0054] S2. Prepare ABS emulsion: add acrylonitrile, styrene monomer and polybutadiene latex into the reaction kettle, and add emulsifier and initiator, and the reaction temperature is 80°C-90°C to obtain ABS emulsion;

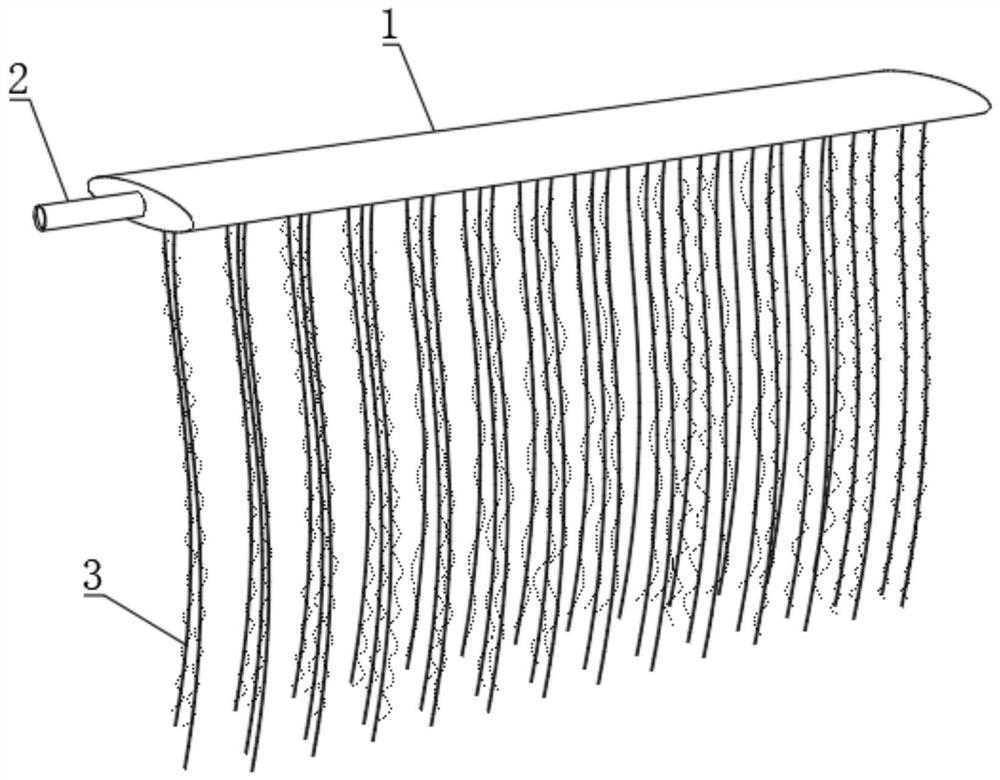

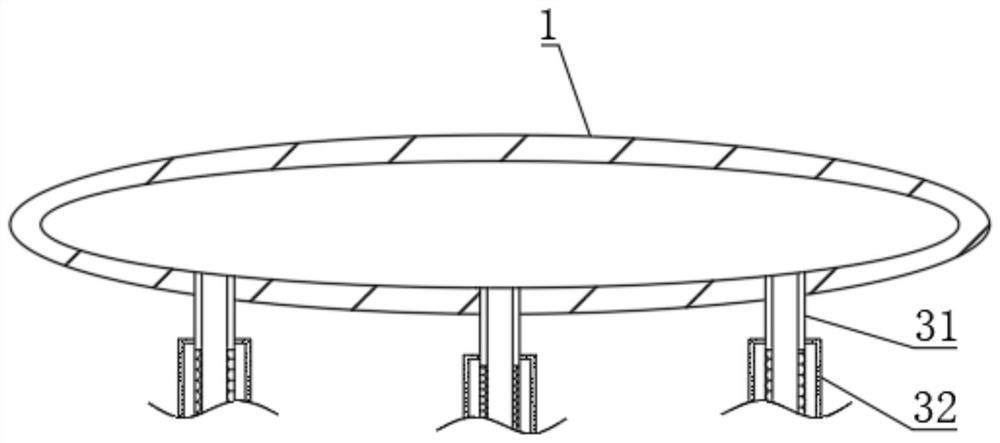

[0055] S3, with the help of the carrier: add coagulant to the stirring tank, and then hang the particle carrier curtain (for figure 2 The structure shown) is placed in the coagulant, passed into the ABS emulsion, and coagulated with stirring, and the coagulation temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com