An angle surface clamping device and its clamping method

A clamping device and angle surface technology, applied in the field of tooling and fixtures, can solve the problems of quality defects of parts, many pressing mechanisms, and many steps, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

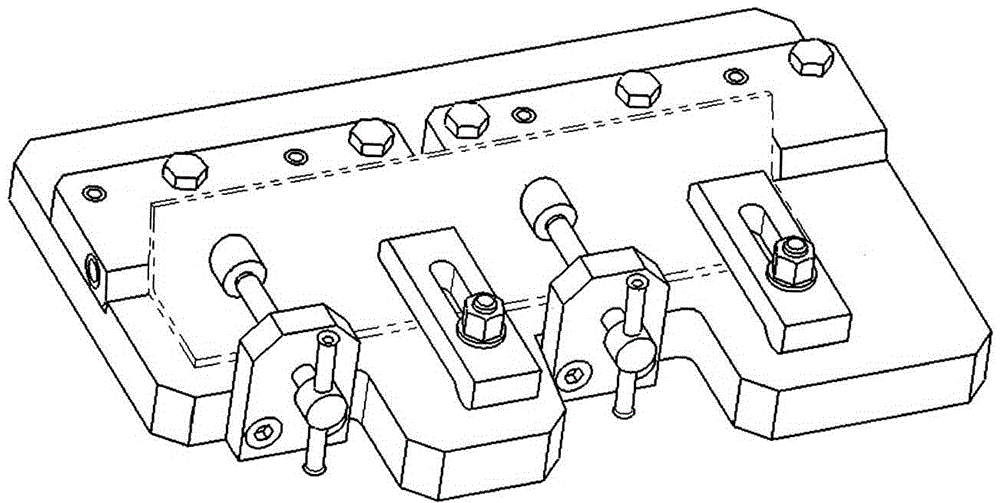

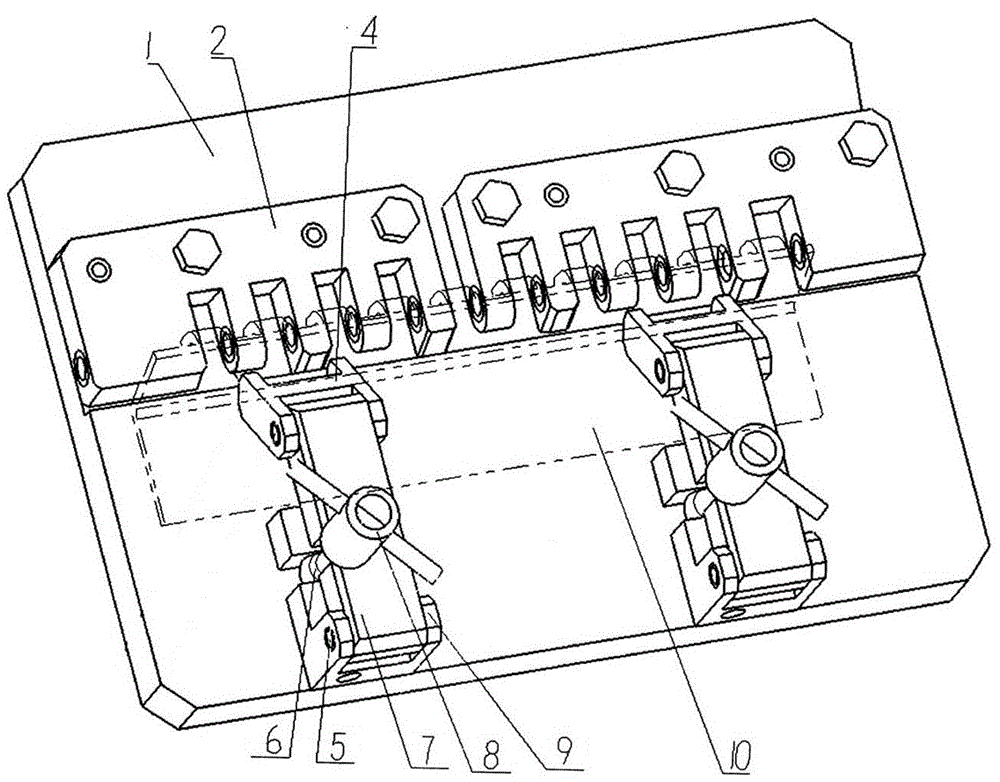

[0014] Such as figure 2 As shown, an angle surface clamping device is provided with a positioning assembly 2 at one end of the bottom plate 1, and a fork seat 9 at the other end. The end of the fork seat 9 is movably connected to the pressure plate 7 through a cylindrical pin 5, and the pressure plate 7 is The end is provided with a briquetting block 4, and the front end of the briquetting block 4 is a semi-cylindrical structure, and is bent downward at an angle along the surface of the pressing plate 7; the fork seat 9 and the pressing plate 7 are respectively provided with corresponding opening slots and opening slots. A bolt 6 is arranged inside, and the handle nut 8 is threadedly connected with the upper part of the bolt 6 and presses the pressure plate 7 tightly.

[0015] The positioning assembly 2 is divided into several pieces and evenly distributed, several opening grooves are arranged on the surface of the positioning assembly 2, and coaxial through holes are provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com