Material lifting mechanism

A lifting mechanism and material technology, applied in the field of lifting, can solve the problems of difficulty in ensuring work quality, easy to cause pollution, affecting the yield of finished products, etc., and achieve the effect of facilitating the replacement of materials and cleaning work, improving work stability, and reducing collision strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

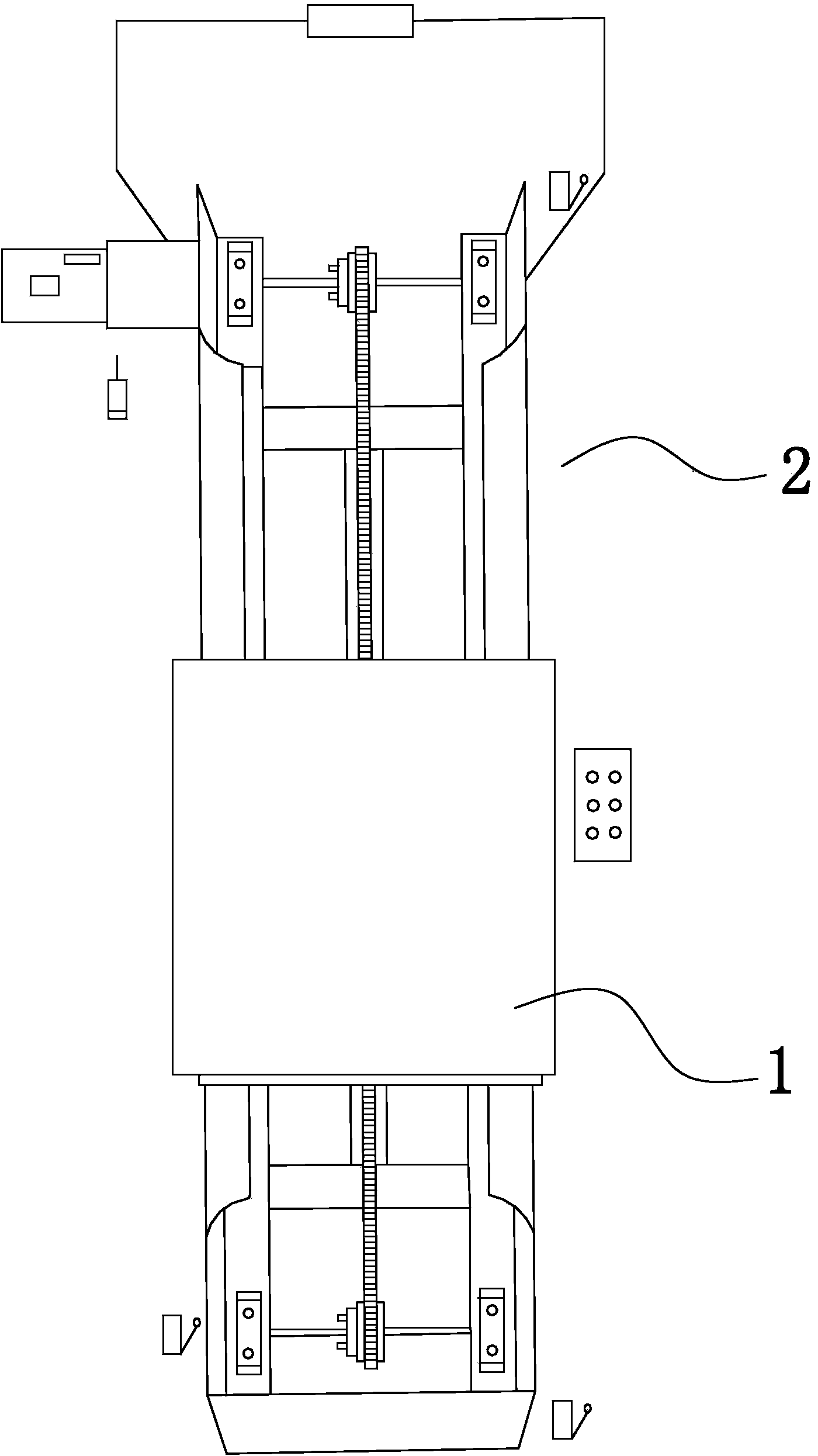

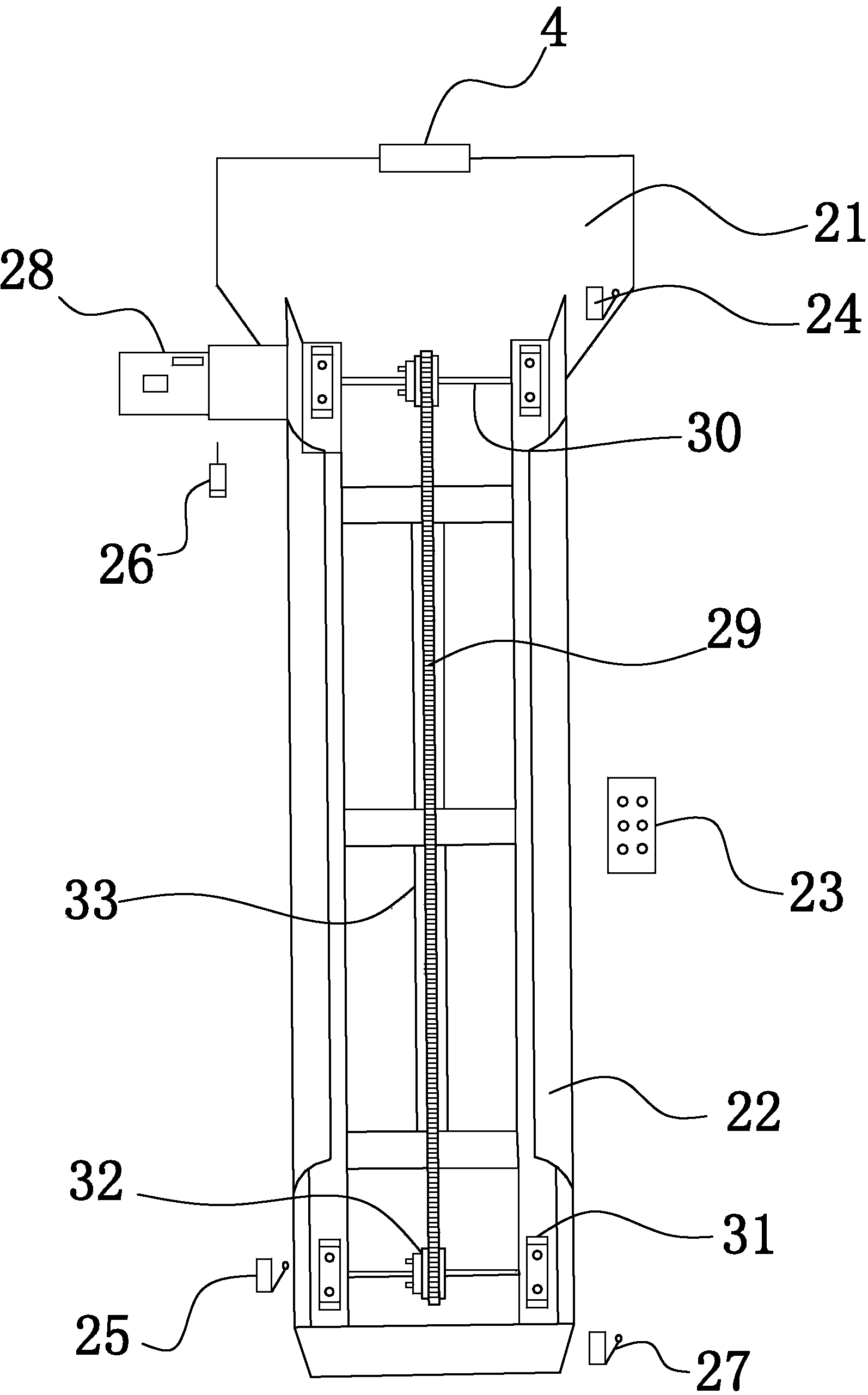

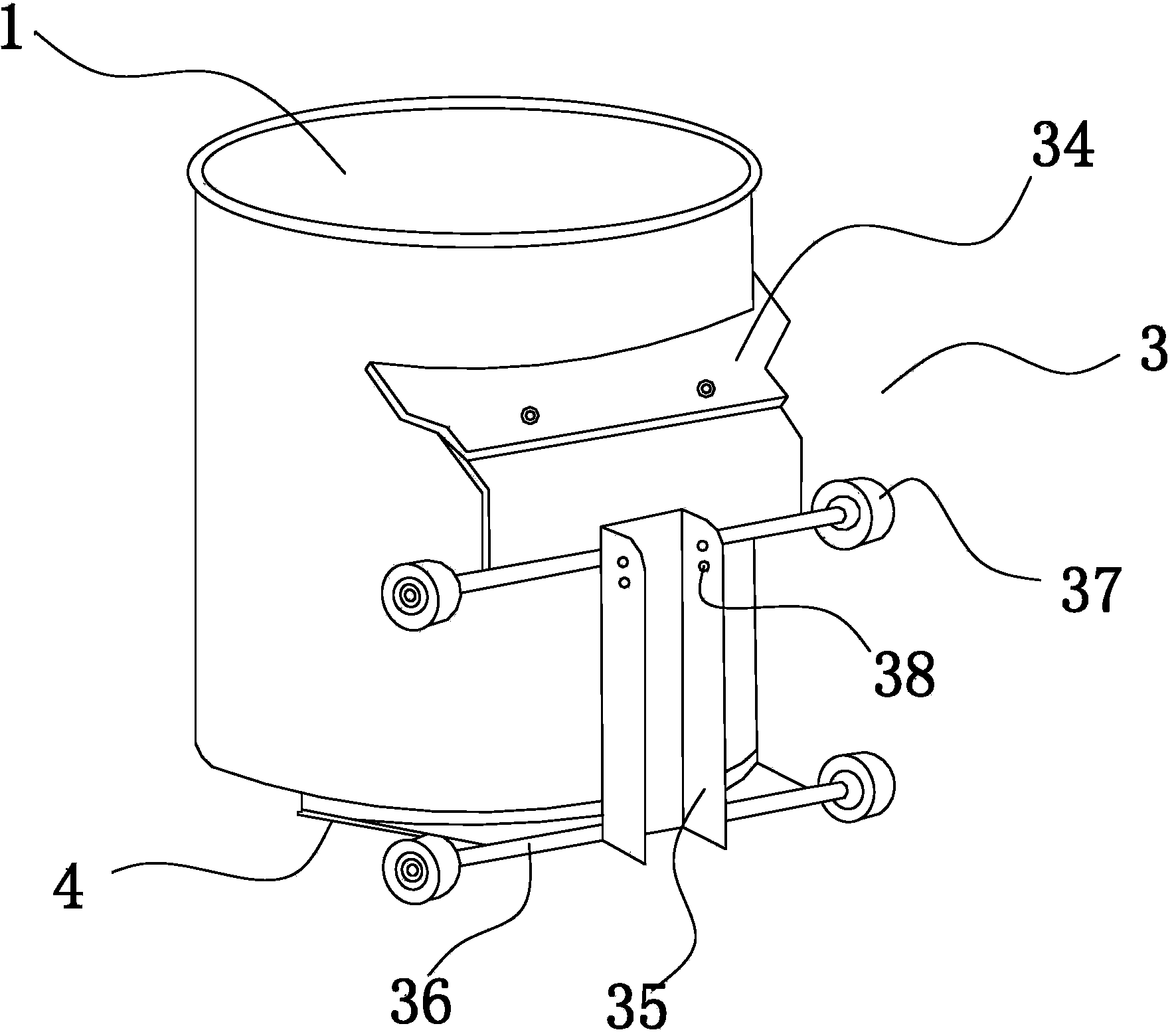

[0024] see Figure 1 to Figure 3 , a material lifting mechanism provided in this embodiment includes a container 1, which also includes a lifting mechanism, and a mounting bracket 3 compatible with the lifting mechanism 2 is fixed on the outer wall of the container 1. There is a lifting mechanism 2, which can automatically transport the container 1 containing the material to a predetermined position accurately and quickly, with high reliability and effectively improves production efficiency; the lifting mechanism 2 includes a vertical support 21, a transmission mechanism and A control assembly for controlling the operation of the transmission mechanism. The transmission mechanism is arranged on the vertical support 21 and parallel to its long side direction, and a guide slide parallel to its transmission direction is arranged symmetrically on both sides of the transmission mechanism. Rail 22. Described control assembly comprises a controller 23 and the upper limit switch 24 t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap