Locking mechanism

A locking mechanism and locking technology, which is applied in the direction of garbage receptacle, transportation and packaging, etc., can solve problems such as labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

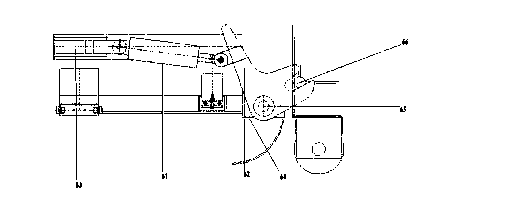

[0007] A locking mechanism includes a pin cylinder 61 , a locking dial 62 , a pin support 63 , a rotating shaft seat 64 , and a rotating shaft 65 . Pin shaft oil cylinder 61 is respectively connected with pin shaft support 63 and locking shift block 62 welded on the casing by pin shaft, and rotating shaft 65 is welded on the locking shift block 62 and can rotate around shaft seat 64. Locking shift block 62 has the notch that bolt 66 matches on the rear door. The pin shaft oil cylinder control device can control the pin shaft oil cylinder 61 to stretch out and retract to drive the locking dial 62 to rotate, so that the gap of the locking dial 62 is located at the bolt 66 on the rear door of the dustbin, closes the rear door, and rotates away from the dustbin rear door On the bolt 66, open the rear door in two states. When it is necessary to open or close the rear door, only the controller can be operated to realize remote operation to open or close the rear door.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com