Assembled frame structure node friction damper

A friction damper and frame structure technology, which is applied to building components, shockproof, etc., can solve the problems that the shock absorption effect is difficult to reach the expected value, the production cost is low, the structure is complicated, etc., and the construction is simple, the production cost is low, and the application range is wide. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

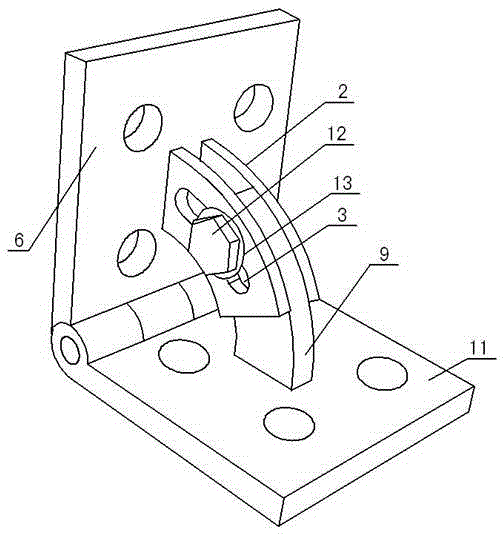

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

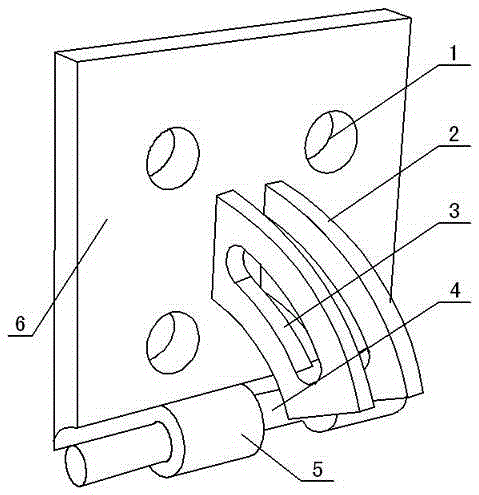

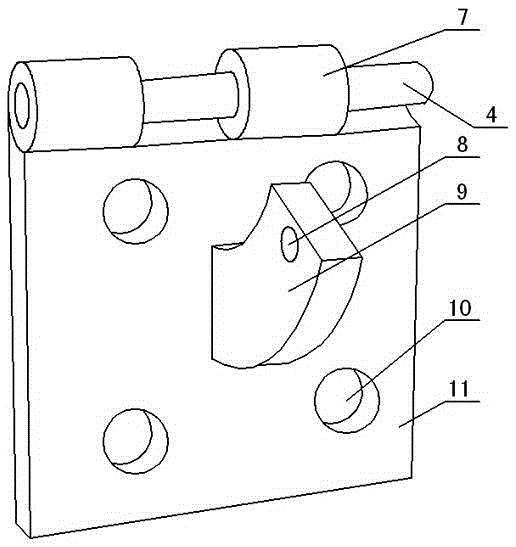

[0019] See attached Figure 4 The friction damper for the node of the assembled frame structure disclosed in the present invention is installed at the beam-column node of the assembled frame structure. See attached Figure 1-3 , it includes double friction plate, single friction plate and compression bolt 12.

[0020] The double-friction plate comprises a rectangular double-friction plate body 6 and a double-friction plate 2, and the double-friction plate 2 is two fan-shaped plates arranged side by side on the surface of the double-friction plate body 6. The arc angles are respectively provided with arc-shaped round head slideways 3 .

[0021] The single friction plate includes a rectangular single friction plate body 11 and a single friction plate 9. The single friction plate 9 is a fan-shaped plate fixed on the surface of the single friction plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com