Planar torsion spring of flexible joint

A technology of planar torsion springs and flexible joints, applied in the field of robotics, can solve the problems of small maximum relative rotation angle and small external force torque, and achieve the effect of improving reliability and good performance parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

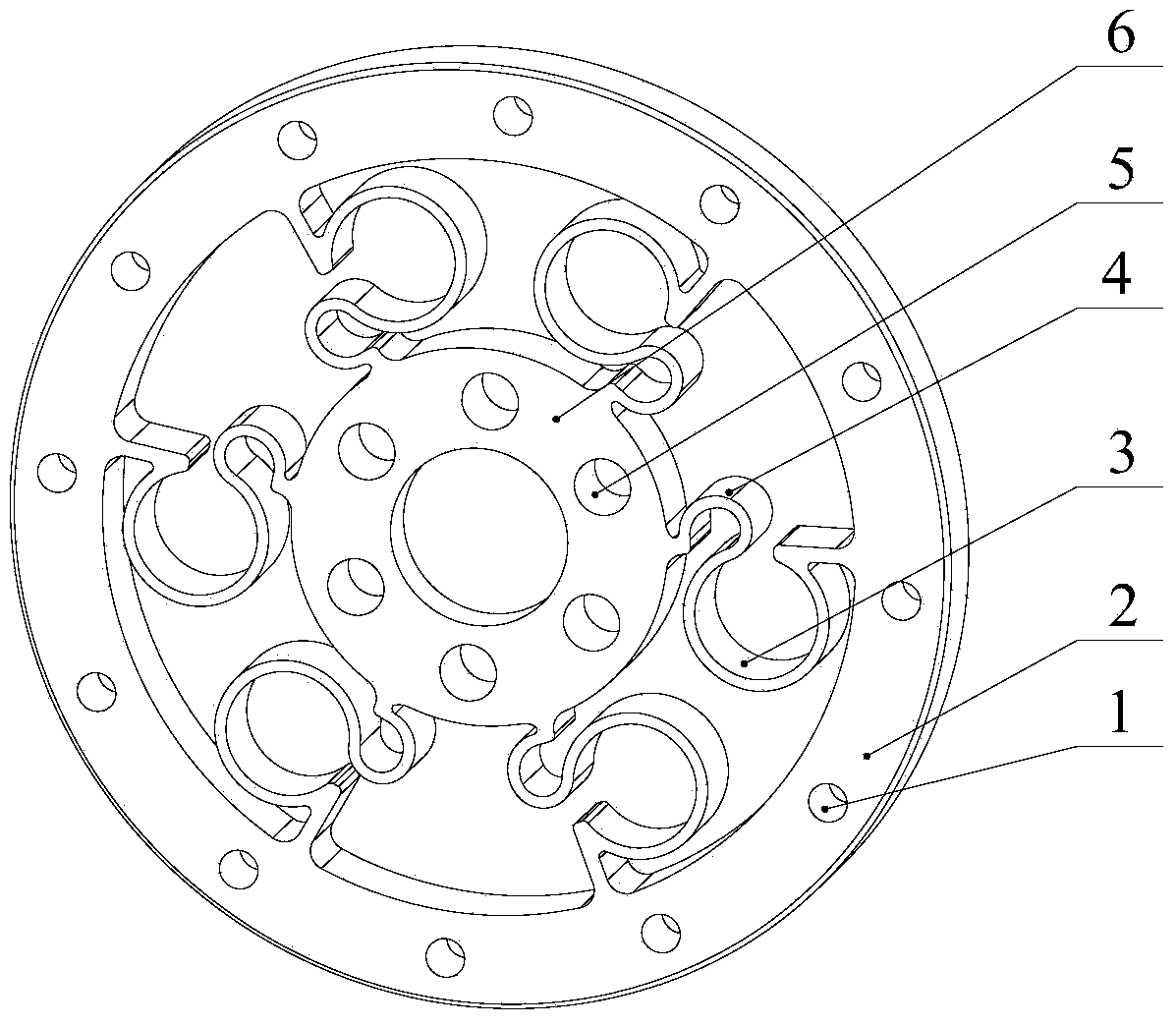

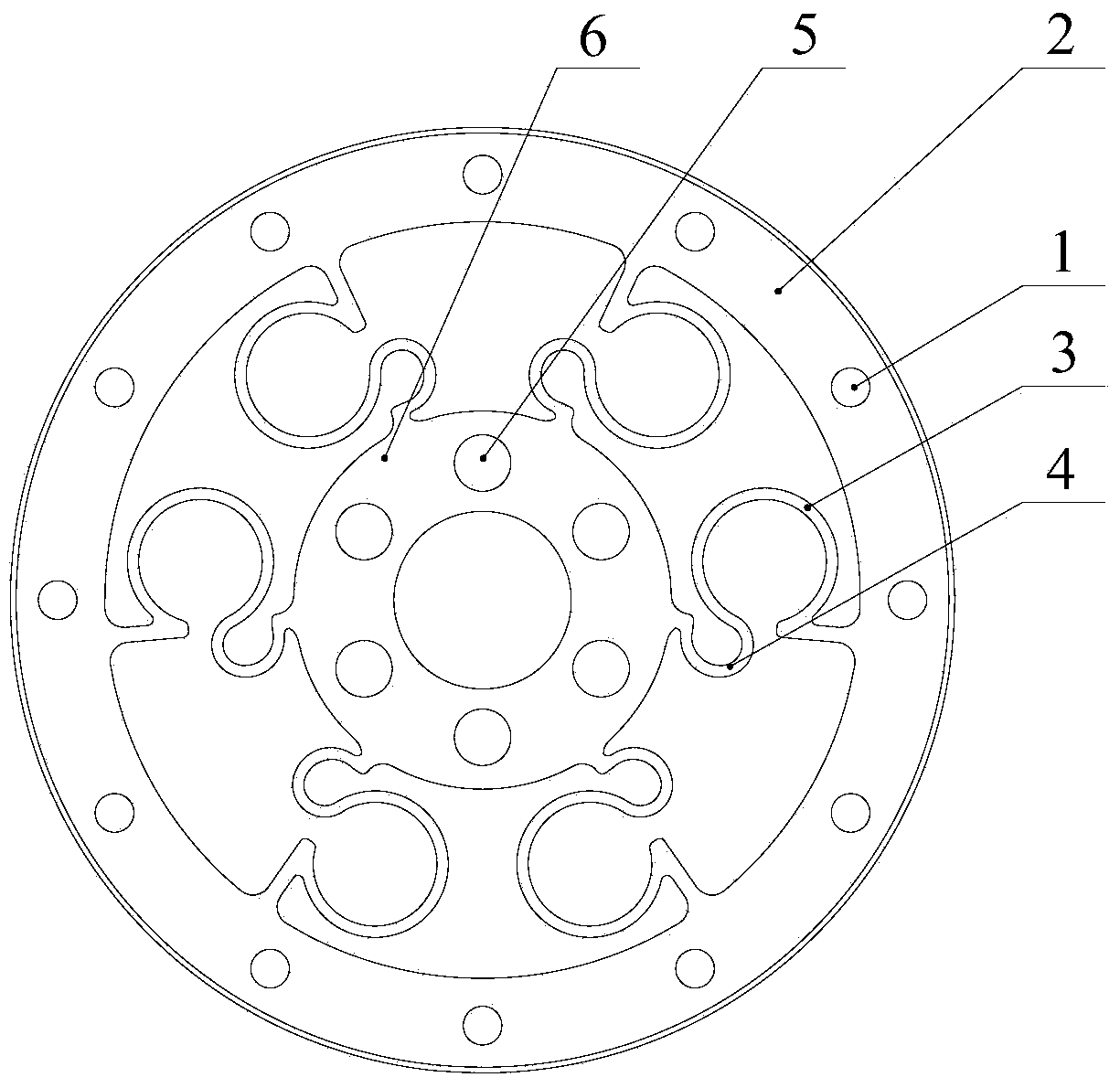

[0029] Such as figure 1 , 2 As shown, a planar torsion spring of a flexible joint includes an inner ring 6, an outer ring 2, and three elastic body units fixed between the inner ring and the outer ring, and each elastic body unit is composed of two symmetrical elastic bodies , each elastomer has two arc segments. In the same elastic body, the openings of the two arc segments are opposite to each other, and both arc segments are superior arcs, wherein the arc segment fixed to the outer ring is the outer elastic arc piece 3, and the arc segment fixed to the inner ring is The segment is the inner elastic arc 4, and the outer elastic arc and the inner elastic arc are tangent to each other in the same elastic body. The ratio of the radius of the outer elastic arc to the radius of the inner elastic arc is:

[0030] 1:10~10:1, according to different application occasions, the plane torsion spring with different performance can be obtained by changing the radius ratio. In order to...

Embodiment 2

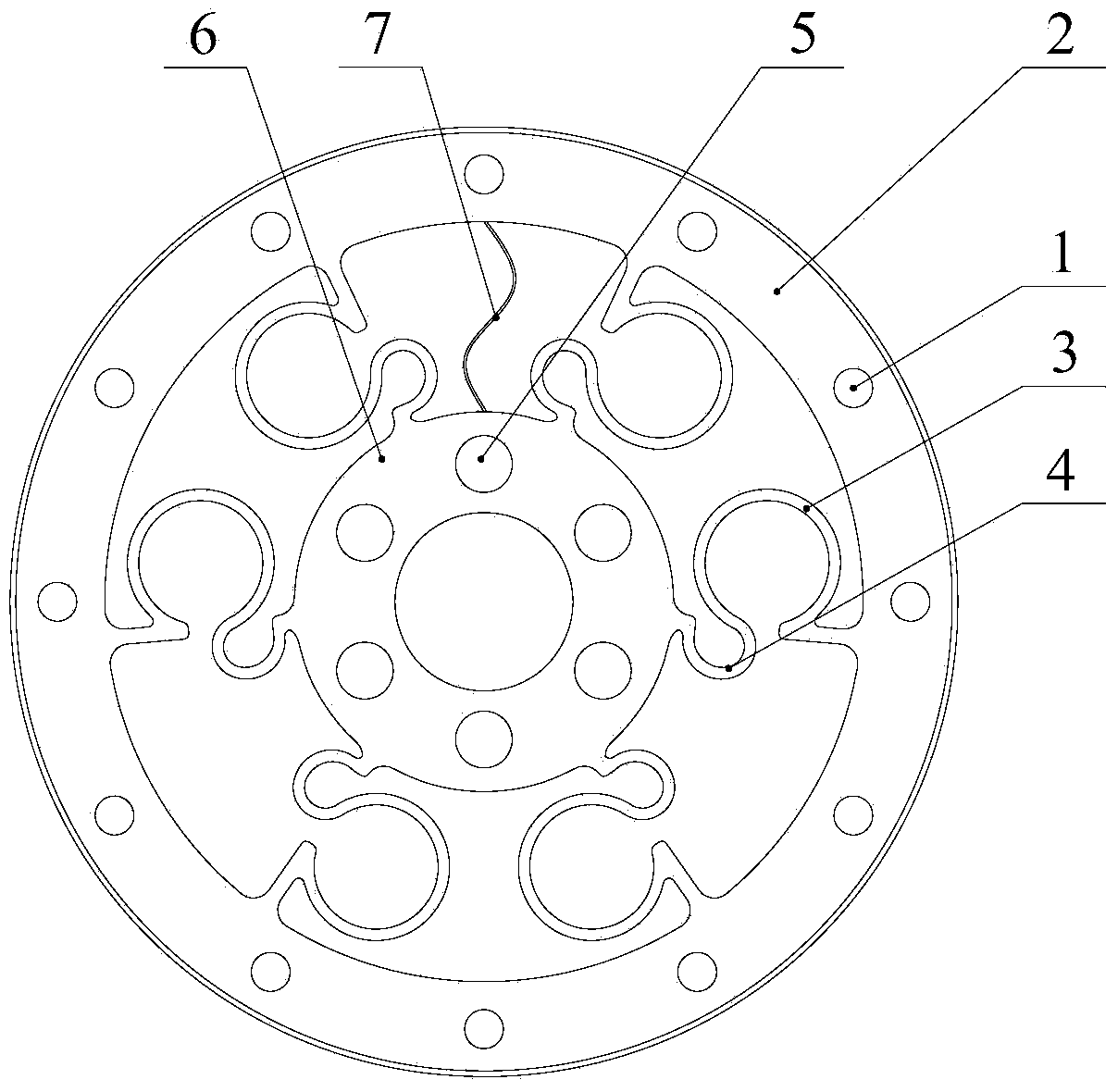

[0050] Such as image 3 As shown, a planar torsion spring of a flexible joint, this embodiment adds a limit lock 7 on the basis of Embodiment 1. One end of the spacer cable 7 is fixed to the outer ring, and the other end is fixed to the inner ring. When the outer ring and the inner ring rotate to a certain position, the spacer cable is straightened to limit the further relative rotation of the outer ring and the inner ring to prevent excessive torque. When it is large, it will damage the plane torsion spring, and the limit cable plays the role of limit protection.

[0051] The limiting cable 7 can be arranged between two adjacent elastic body units or between two elastic bodies of the elastic body unit. There can be one or more limit cables.

Embodiment 3

[0053] Such as Figure 6 As shown, a planar torsion spring of a flexible joint, the difference between this embodiment and Embodiment 1 is that the ratio of the radius of the outer elastic arc to the radius of the inner elastic arc is 1:0.61.

[0054] Through the simulation software, the maximum torque of this embodiment is 8.92 N·m, and the maximum deformation angle is 3.01°. Through the simulation, it can be seen that by changing the ratio of the radius of the outer elastic arc to the radius of the inner elastic arc, different external force torques and deformation angles can be obtained, which can be selected according to different requirements of robot joints. And the performance of the plane torsion spring is better than other torsion springs in the past.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com