Titanium alloy five-blade connecting rib horizontal check valve of hoop joint

A technology of clamp joints and titanium alloys, applied in the directions of lift valves, valve details, control valves, etc., can solve the problems of increased energy consumption, fluctuations in the operation of pressure reducing devices, and high cost of clearing blockages, so as to avoid unexpected failures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with accompanying drawing, the present invention will be further described with embodiment:

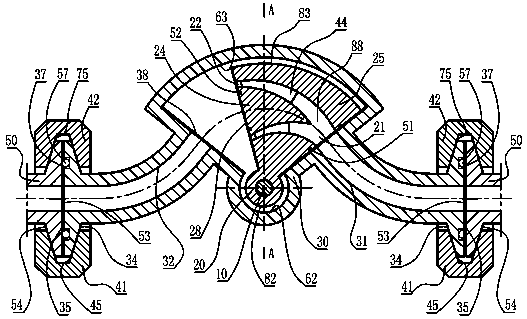

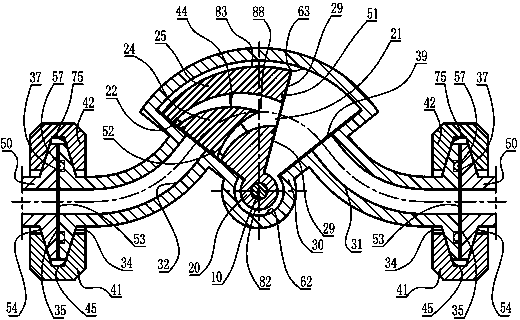

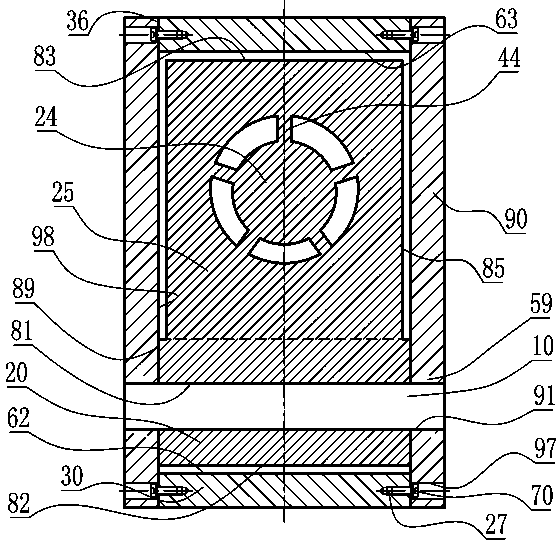

[0031] Figure l, figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 with Figure 7 Among them, a clamp joint titanium alloy five-lobed rib horizontal check valve, including a cylindrical shaft 10, a swing valve core 20, a clamp joint valve body 30, a fastening screw 70 and an outer end cover 90, as an improvement: the The outer ends of the outlet elbow 31 and the inlet elbow 32 on the clamp joint valve body 30 have a valve pipe plane 35, the inner side of the valve pipe plane 35 is a valve pipe cone surface 34, and there is a pipe on the end of the outer pipe joint 50. The road plane 53 is close to the valve tube plane 35, and the inner side of the pipeline plane 53 of the outer pipeline joint 50 is the pipeline cone surface 54 corresponding to the valve tube cone surface 34; the paired assembly consists of two sets of bolts The lower half tile 41...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com