Sintering area device of solar cell sintering furnace

A solar cell and sintering zone technology, applied in furnaces, furnace types, lighting and heating equipment, etc., can solve the problems of easy temperature crossover, affecting sintering quality, unfavorable temperature zone division, etc., to prevent mutual temperature crossover and ensure sintering. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

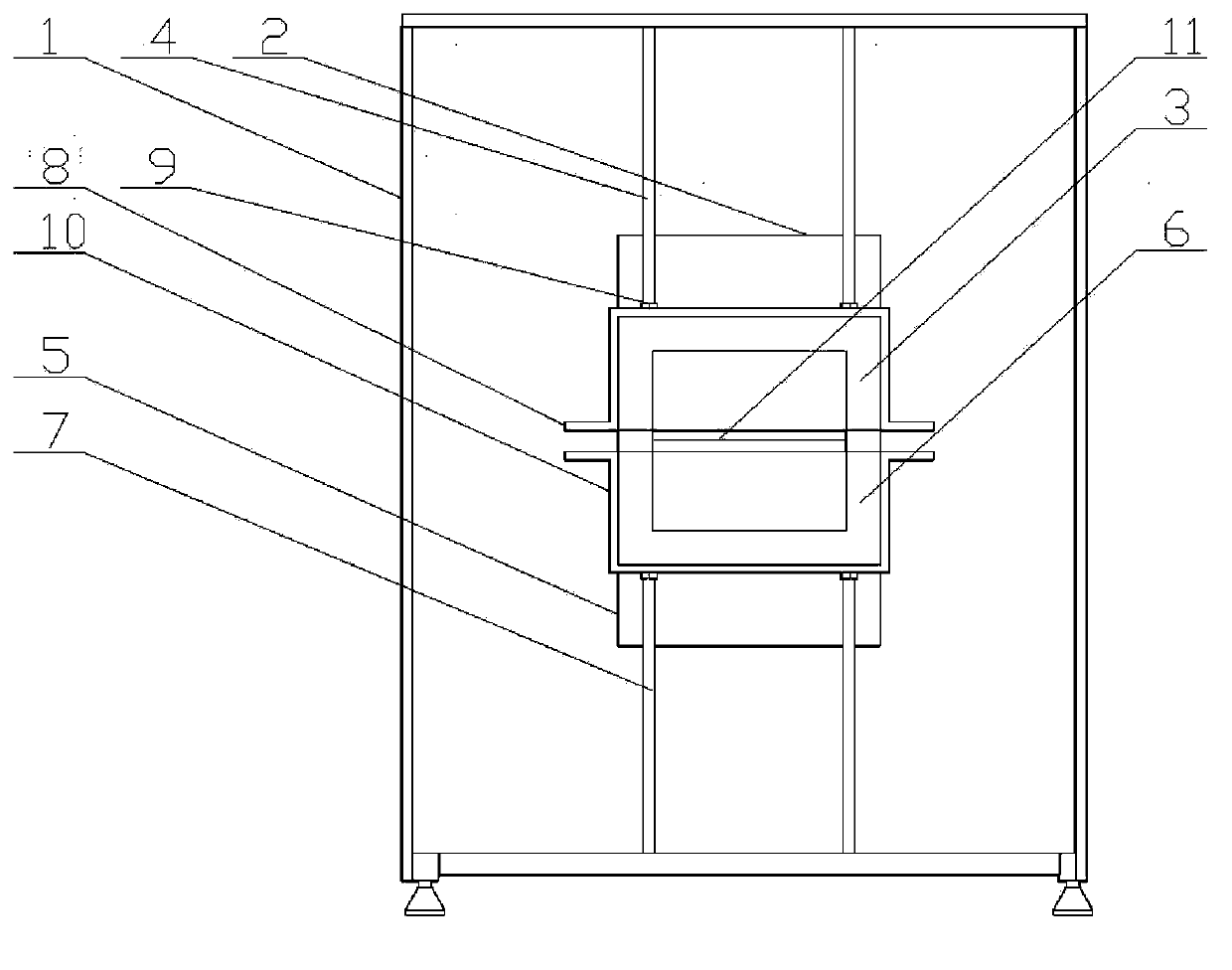

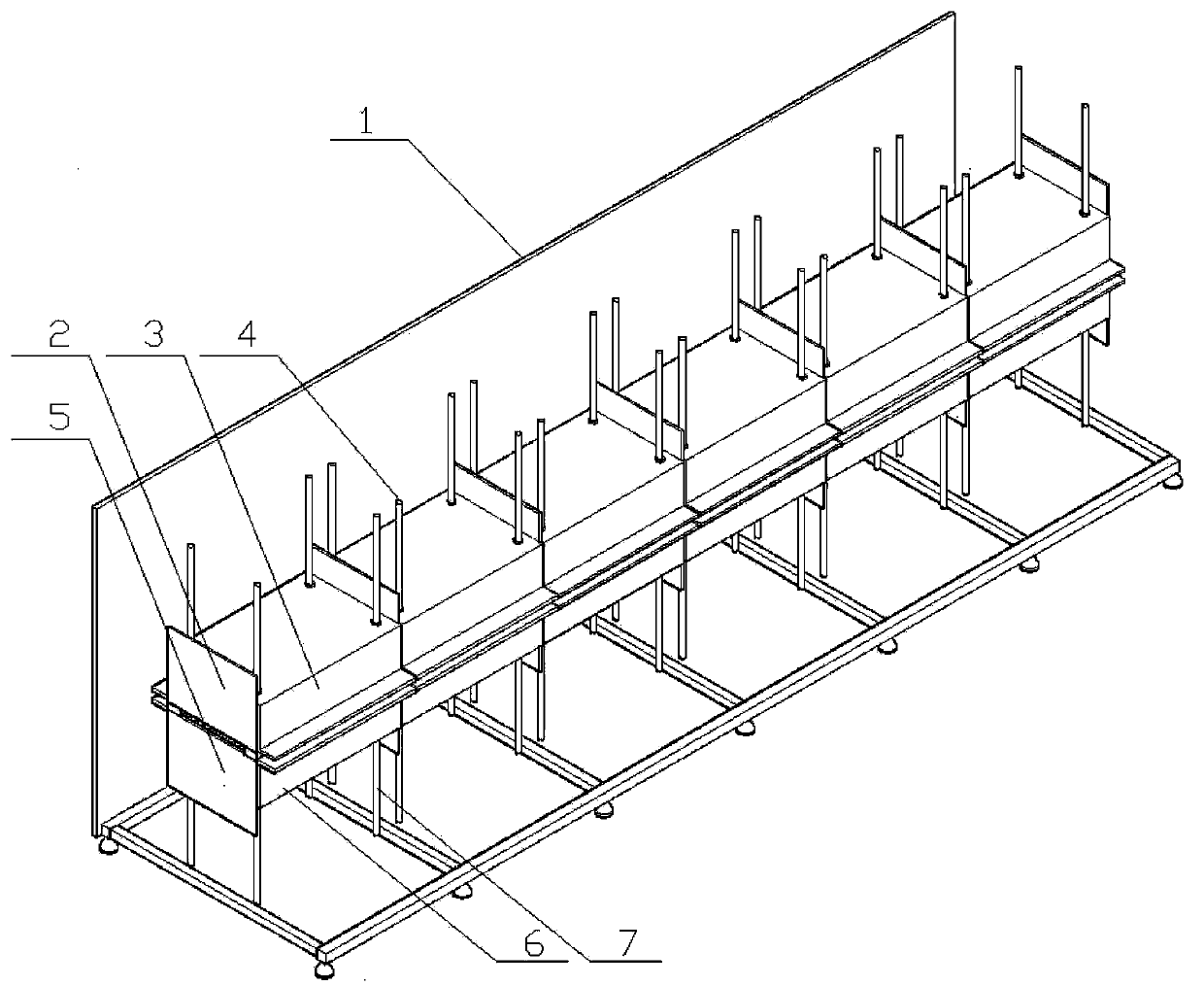

[0017] Such as figure 1 , figure 2 As shown, it shows an embodiment of the present invention, the sintering area device of the solar cell sheet sintering furnace of the present invention, including the transmission mesh belt 11 used to transport the solar cells to be sintered throughout the sintering furnace; and the sintering area frame 1. The frame 1 of the sintering area is composed of stainless steel square tubes, and the outside of the frame composed of stainless steel square tubes is fixed with stainless steel door panels;

[0018] An upper furnace 3 is arranged above the transmission mesh belt 11, and the upper furnace 3 is concave as a whole, and an upper buckle plate 8 is fixedly installed on the outside of the upper furnace 3, and an upper pull rod 4 is fixedly installed on the upper surface of the upper buckle plate 8 by fastening bolts 9. The pull rod 4 is vertically arranged, and its top end is fixedly connected to the inner top plate of the frame 1 in the sinte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com