Blind window drying bed fire grate bar and smelting production method thereof

A production method and shutter technology, applied in the field of pellet production equipment, can solve the problems of clogging of gaps, restricting the output of pellets, etc., and achieve the effects of reducing the clogging rate, being less prone to deformation and corrosion, and improving the ventilation rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

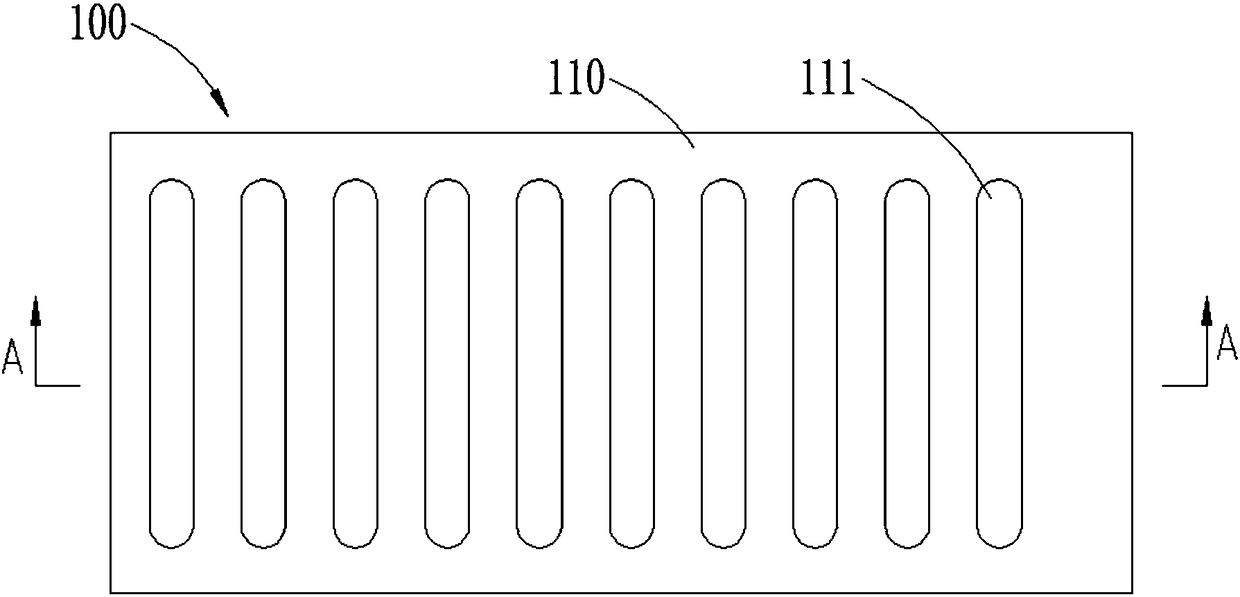

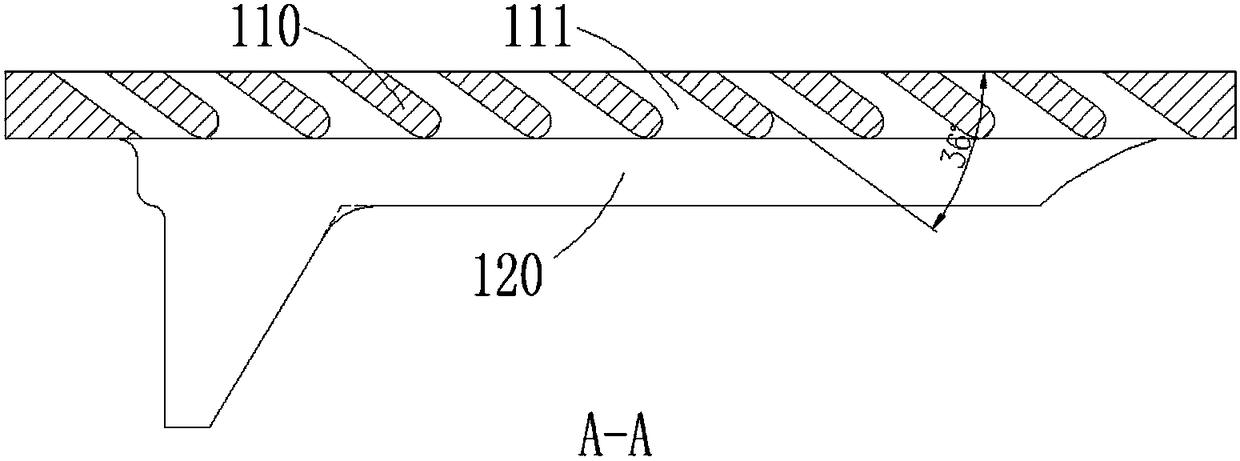

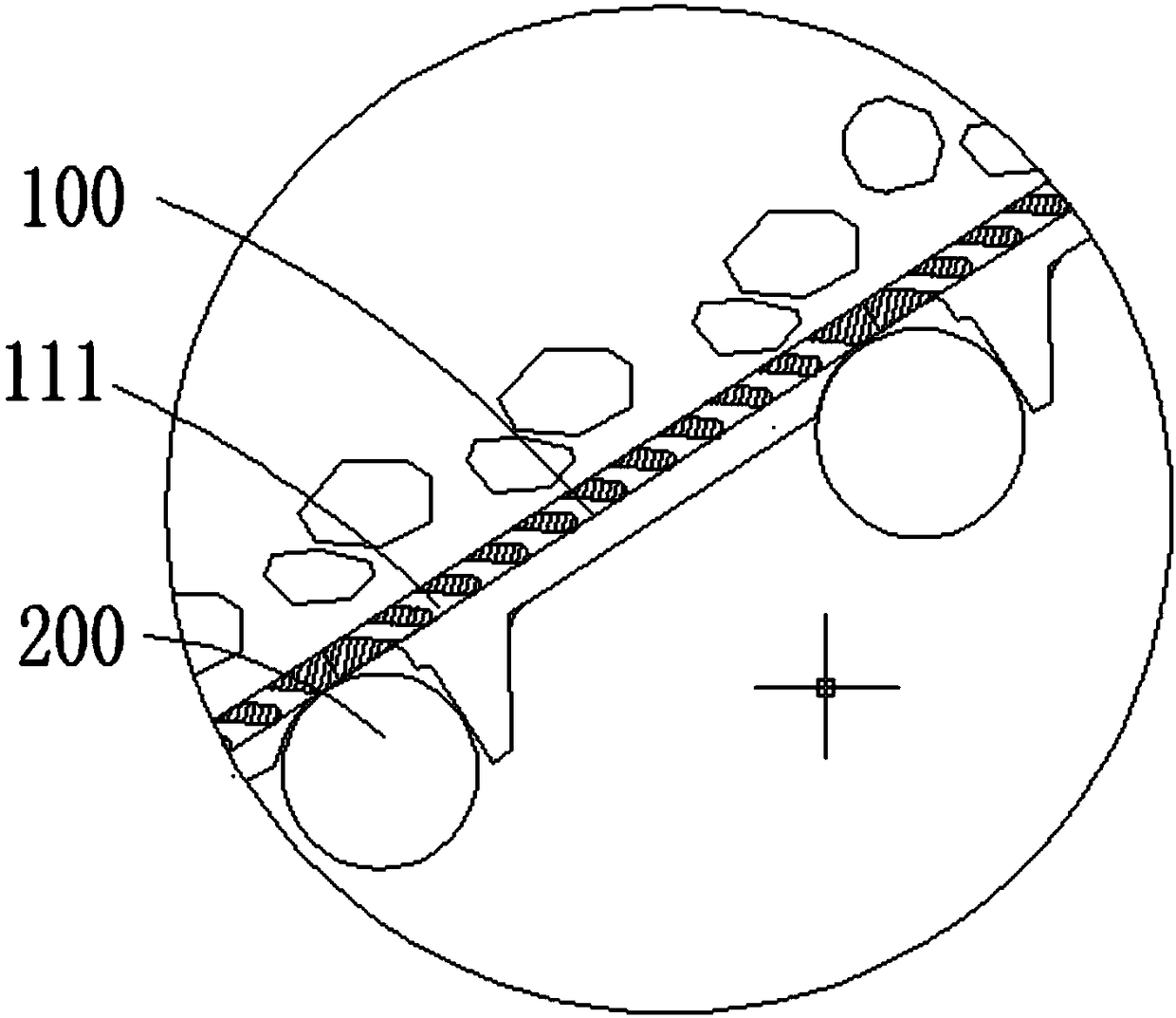

[0048] Such as Figure 1 to Figure 3 As shown, the louvered drying bed grate bar 100 of the present embodiment includes a grate bar body 110, webs 120 are symmetrically arranged on both sides of the grate bar body 110, and bar holes 111 are provided on the grate bar body 110, and the bar holes 111 is inclined and the air inlet is flaring. When in use, the bar hole 111 is in a horizontal state; both ends of the web 120 are processed into a shape that matches the outer surface of the water beam 200 .

[0049] It is worth noting that in the actual production process, 4% to 5% of the green pellets are larger than 18mm (generally, the green pellets are required to be 9 to 18mm). It is 20mm and is a bar hole (in the case of the same ventilation area per unit area), the grate bar hole is very easy to be blocked. From the production practice, the blockage rate is about 20% to 30%, the ventilation rate is reduced, and the unit time The output is reduced, which greatly affects the norm...

Embodiment 2

[0070] A kind of louver drying bed grate bar of this embodiment is similar in structure to embodiment 1, the difference is that, in this embodiment, the hole diameter D is 21mm, and the centerline of the bar hole 111 and the grate bar body 110 The center line forms an included angle of 30°, and the air inlet is flaring. When in use, the bar hole 111 is in a horizontal state, and the grate bar is composed of the following components by weight percentage (wt%): C: 0.38%; Cr: 22.2 %; Si: 3.85%; Ni: 1.04%; Mn: 0.45%; S: ≤0.02%; P: ≤0.02%, and the remaining components are Fe and trace impurities.

[0071] A kind of smelting production method of the louver drying bed grate bar of this embodiment, its smelting process comprises:

[0072] (1) Furnace charge selection: Proportioning is carried out according to the components of the grate bar, and high-chromium scrap steel (with a chromium content of more than 25%) that is rust-free, oil-free, and free of any impurities is used as the c...

Embodiment 3

[0087] A kind of louver drying bed grate bar of this embodiment is similar in structure to embodiment 1, the difference is that, in this embodiment, the hole diameter D is 25mm, and the center line of the bar hole 111 is in line with the grate bar body 110 The center line forms an included angle of 36°, and the air inlet is flaring. When in use, the bar hole 111 is in a horizontal state, and the grate bar is composed of the following components by weight percentage (wt%): C: 0.32%; Cr: 24.80 %; Si: 3.0%; Ni: 0.81%; Mn: 0.5%; S: ≤0.02%; P: ≤0.02%, and the remaining components are Fe and trace impurities.

[0088] A kind of smelting production method of the louver drying bed grate bar of this embodiment, its smelting process comprises:

[0089] (1) Furnace charge selection: Proportioning is carried out according to the components of the grate bar, and high-chromium scrap steel (with a chromium content of more than 25%) that is rust-free, oil-free, and free of any impurities is u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com