Bearing temperature measuring probe fixing device

A technology of a temperature measuring probe and a fixing device, which is applied in the field of bearings, can solve the problems of difficult control of pressing force, easy breaking of thermocouple wires, opening holes, etc., and achieves the effect of simple and convenient installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

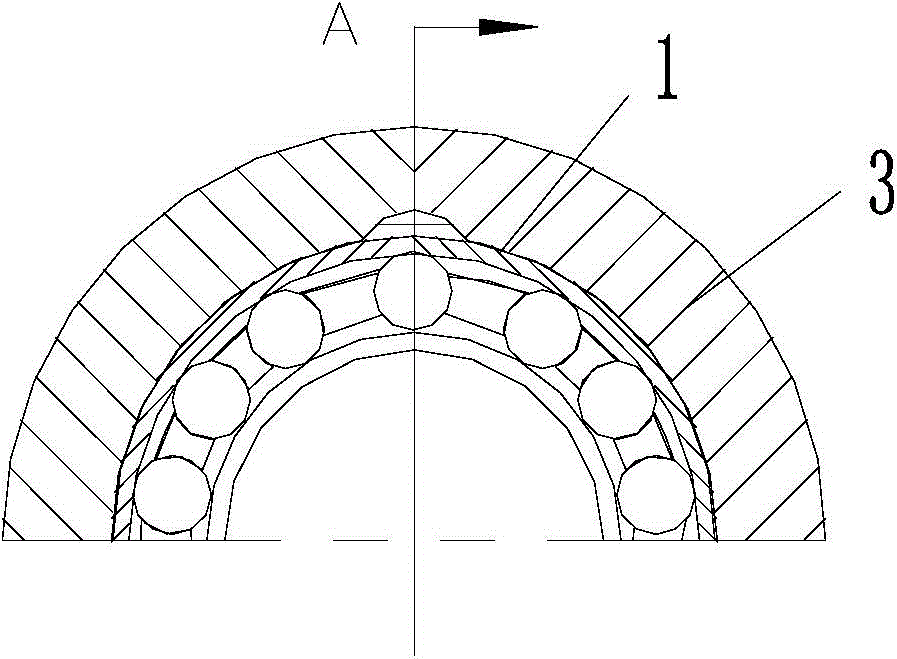

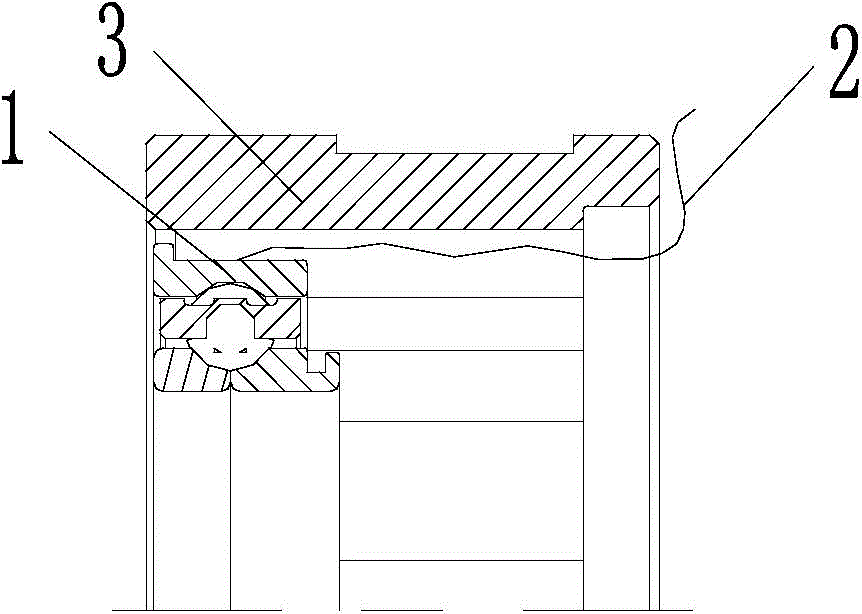

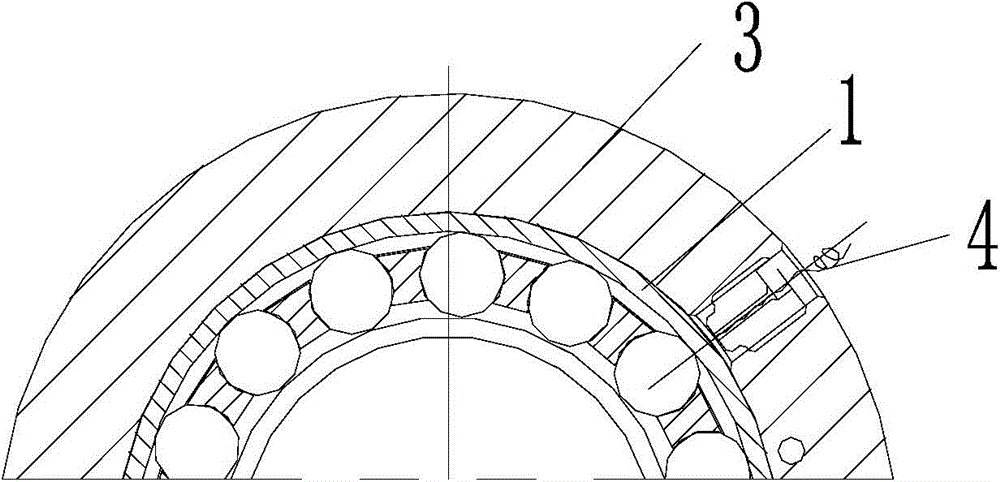

[0031] see Figure 5 , the preferred embodiment of the present invention provides a bearing temperature measuring probe fixing device, which is used to be installed in the mounting hole of the bearing seat 3, the mounting hole is a stepped hole, and the bearing temperature measuring probe fixing device includes The elastic clamping structure 10 of the temperature probe 7, the support base 20 for supporting the clamping structure 10, and the clamping structure 30 for compressing the clamping structure 10; The installation through hole 11 of the temperature probe 7, the bottom end of the temperature measurement probe 7 is in contact with the outer surface of the bearing ring 1; the support seat 20 is fixed at the step in the installation hole, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com