Device and method for monitoring failure rule of anticorrosive coating in stressed pipeline in real time

A real-time monitoring and internal anti-corrosion technology, applied in pipeline systems, mechanical equipment, gas/liquid distribution and storage, etc., can solve problems such as the lack of corrosion inhibitor coating monitoring methods, and achieve true and reliable test results and consistent initial status. , the effect of facilitating promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

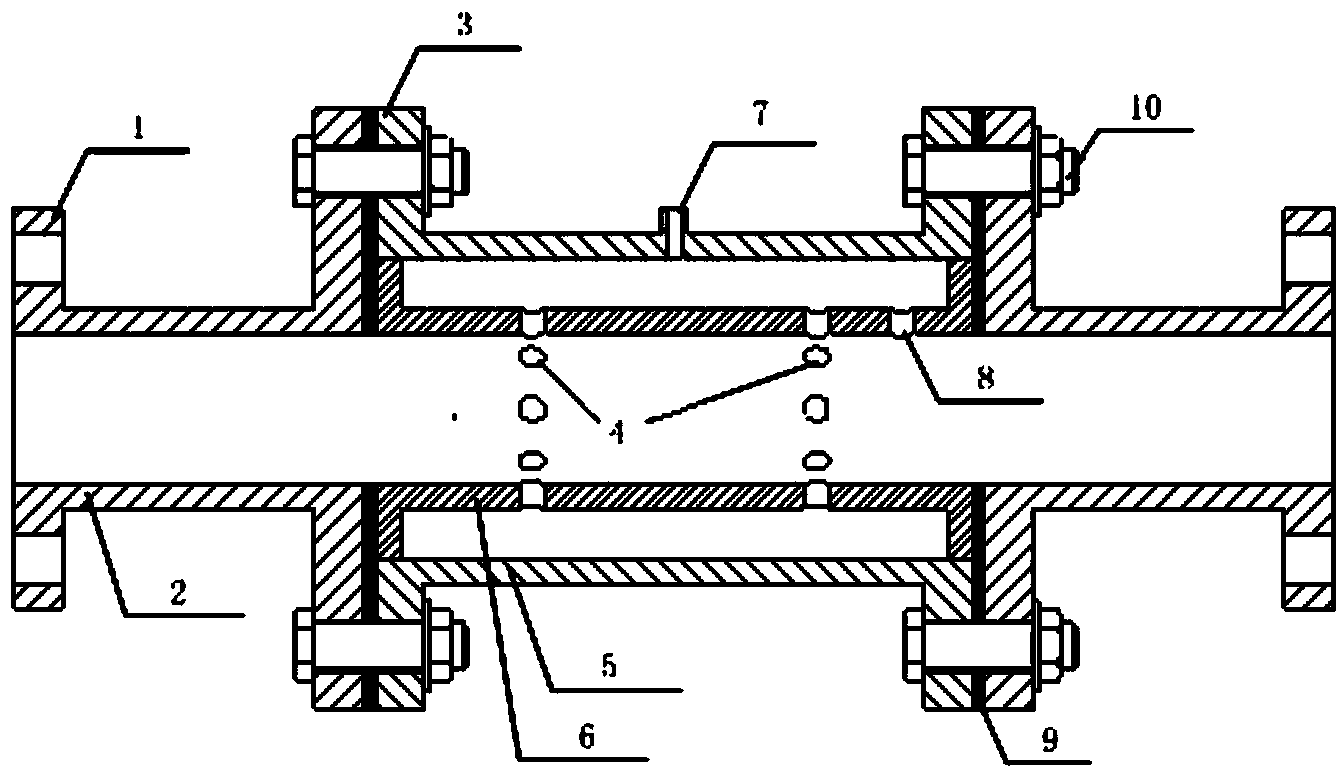

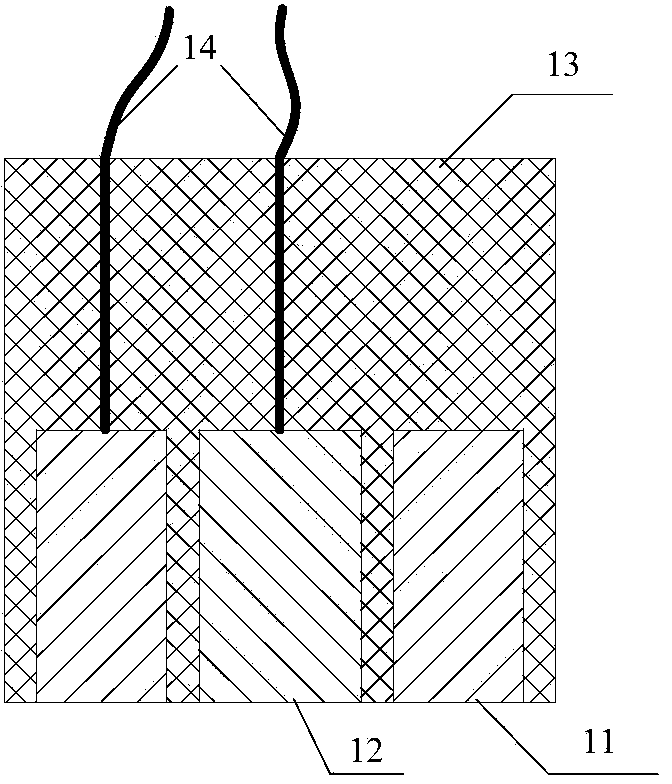

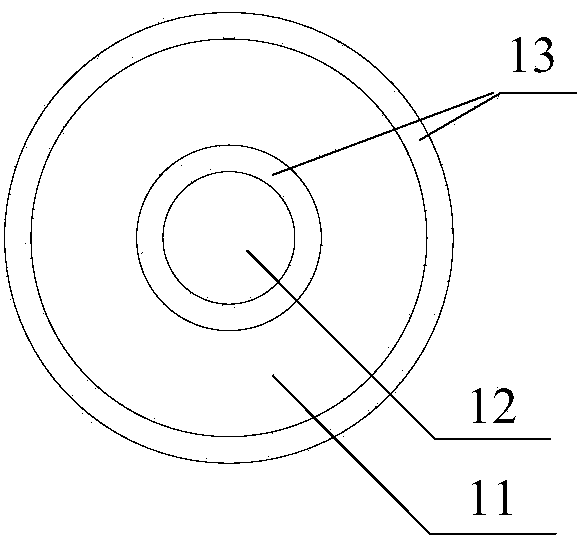

[0021] A device for monitoring the failure law of an anti-corrosion coating film in a pressurized pipeline, comprising: an external flange 1, an external pipe section 2, an outer sleeve 5, an inner sleeve 6 and a test electrode, the external flange 1 is connected to the test pipeline, Outer casing 5 is connected with outer connecting pipe section 2 by fastening bolts 10 and is provided with a sealing ring 9. The inner casing 6 is evenly distributed with electrode jacks 4 in the circumferential direction, and the test electrodes are embedded in the electrode jacks 4, which are kept in contact with the inner wall of the inner casing 6. In the same plane, the outer sleeve 5 is provided with an outlet 7 for leading out the connecting electrode wire 14, and the inner sleeve 6 is provided with a pressure balance hole 8 to keep the pressure on both sides of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com