Adjustable T-type characteristic guided wave welding line detecting device

A characteristic guided wave and weld detection technology, which is used in measuring devices, solids analysis using sonic/ultrasonic/infrasonic waves, and material analysis using sonic/ultrasonic/infrasonic waves, etc. The problem of high cost is to achieve the effect of improving detection efficiency and accuracy, improving reflectivity and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to deepen the understanding of the present invention, an adjustable characteristic guided wave welding seam detection device proposed by the present invention will be further described in detail below in conjunction with specific examples. Limitation of the scope of protection.

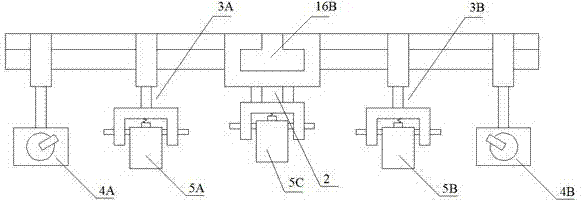

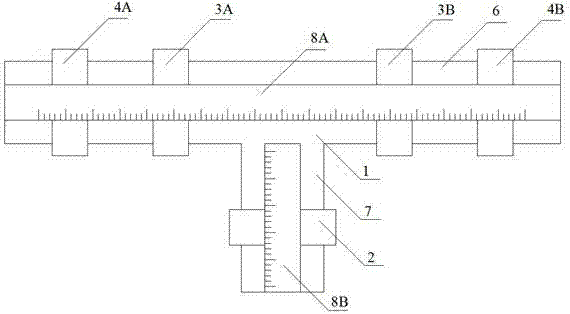

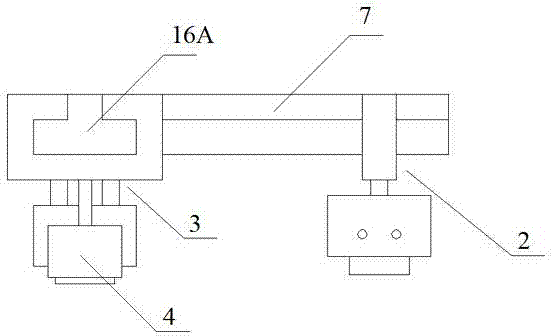

[0028] The T-shaped adjustable characteristic guided wave weld detection device includes a T-shaped main frame 1, a receiving probe loading arm 2, two excitation probe loading arms 3A, 3B, two magnetic table bases 4A, 4B, Two guided wave excitation probes 5A, 5B and a guided wave receiving probe 5C; the main frame 1 is T-shaped, consisting of a guided wave excitation probe frame 6 and a guided wave receiving probe frame 7; the guided wave excitation probe frame 6 and the guided-wave receiving probe frame 7 are respectively provided with inverted T-shaped chute 16A, 16B as a moving track; On, the magnetic base 4A, 4B is also respectively installed on the inverted T-shaped chute 16A of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com