A Flexible Probe with Array Sensors for Weld Defect Detection Based on Characteristic Guided Waves

A defect detection and characteristic guided wave technology, which is applied in the direction of instruments, measuring devices, scientific instruments, etc., can solve the problems of low surface adhesion, low detection accuracy, and loose adhesion, etc., to achieve improved reflectivity and simple and convenient operation , Enhance the effect of echo intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

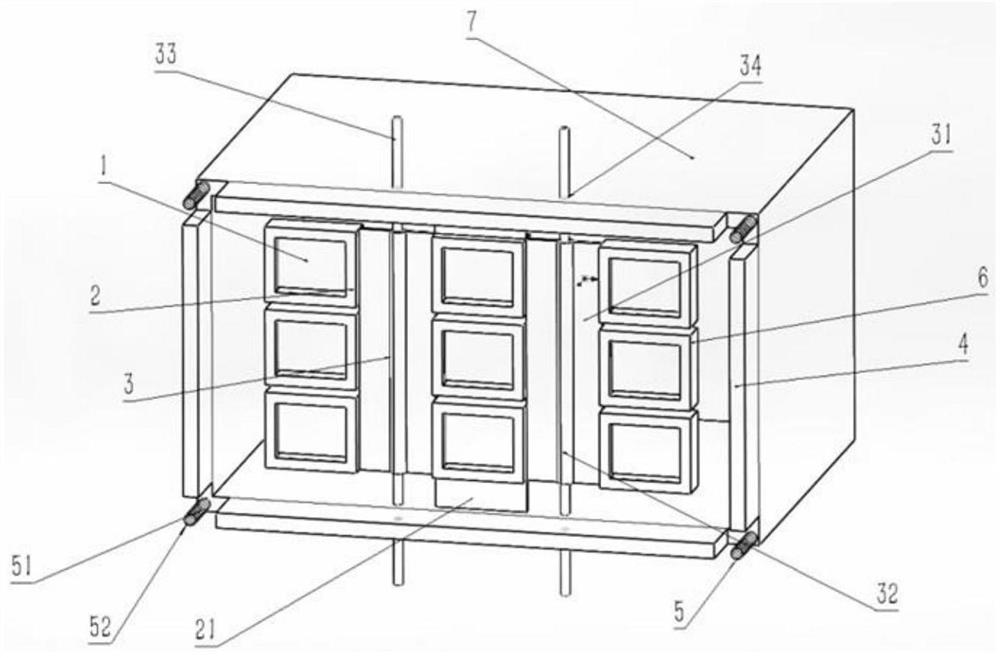

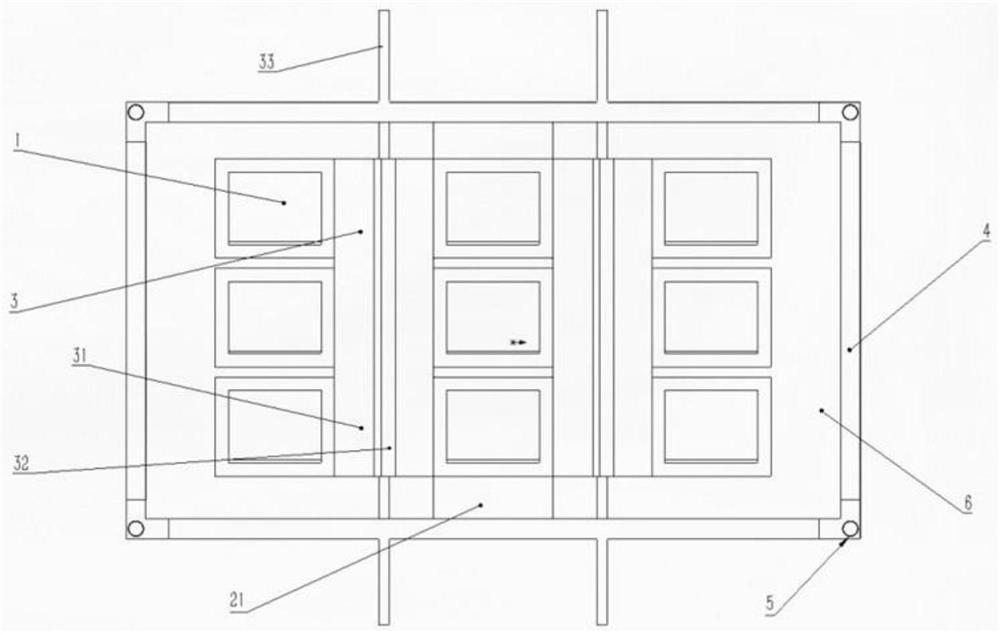

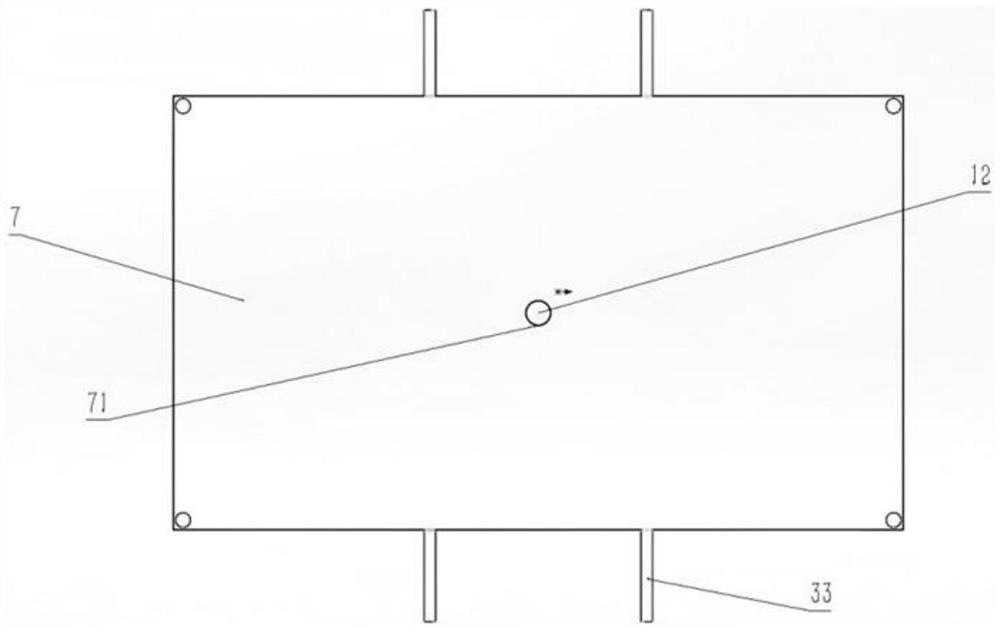

[0027] Such as Figure 1-3 As shown, the present invention is applicable to the detection of the butt weld of two steel plates and the annular weld of some pipelines, including 9 piezoelectric sensor units 1 arranged in an array, and 9 corresponding sensor placement devices 2, with the middle The device is arranged in a central axis array; the base axis interference fit angle adjustment device 3, the flexible sound-absorbing backing plate 4, the electromagnet adsorption fixing device 5, the sound-absorbing material filler 6, and the shell 7, the shell 7 is a cuboid; The sensor placement device 2 is fixed on the housing 7 through a fixing plate 21 . The flexible sound-absorbing backing plate 4 is arranged around the front end of the entire probe, and is made of mineral wool material, which is respectively glued to the shell 7, so that the probe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com