Method for monitoring three-dimensional temperature and thermal stress of ultra-supercritical steam turbine rotor in real time

A steam turbine rotor, ultra-supercritical technology, applied in mechanical equipment, engine components, machines/engines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

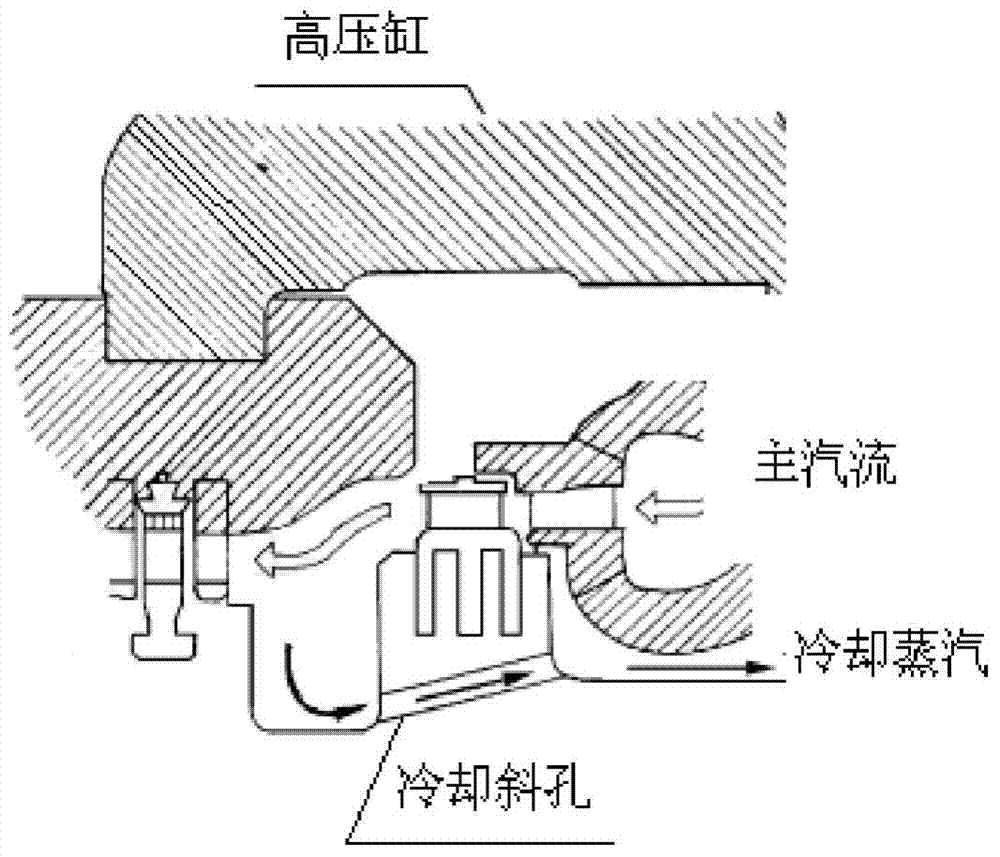

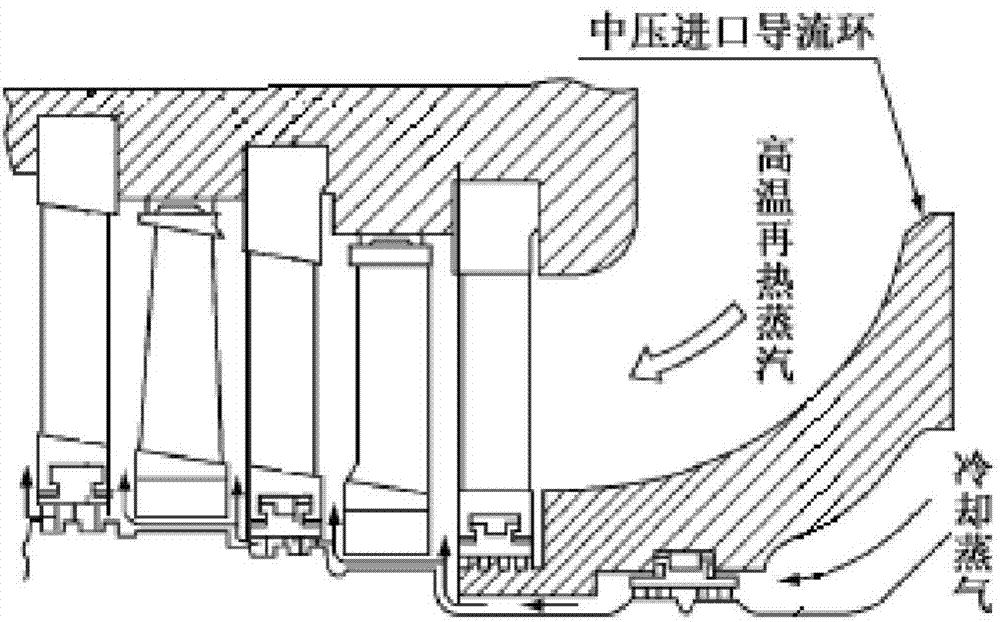

Embodiment Construction

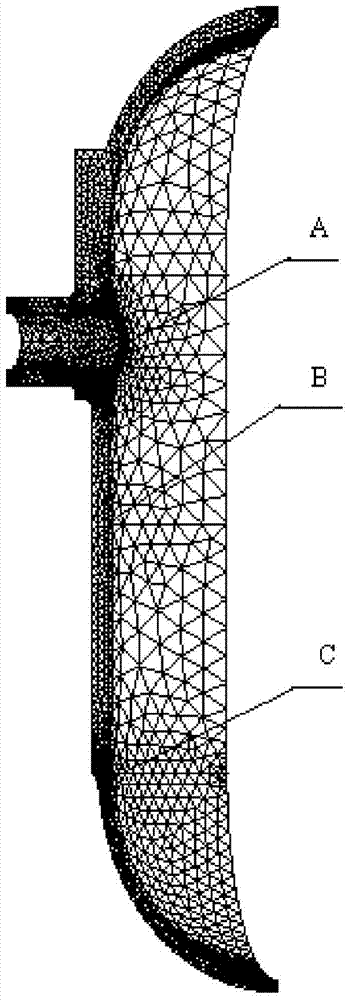

[0104] Because the rotor of the steam turbine rotates at a high speed, it is impossible to directly measure the temperature and stress of the rotor metal. Taking a three-dimensional pressure vessel as the object, the temperature and the position of the monitoring point under the given working conditions are obtained by using the invented model simulation calculation and measurement methods respectively. The stress results are used to verify the calculation accuracy of the proposed model. When the pressure vessel is in operation, its inner surface is in contact with steam for convective heat exchange, and its outer surface is insulated. It has a complex three-dimensional structure, which is very similar to the operating characteristics of an ultra-supercritical steam turbine. The calculation model proposed in this patent is also suitable for this pressure vessel. , but the pressure vessel does not need to rotate during operation, and measuring points can be set on the wall of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com