Liquid filter with an eccentric liquid discharge channel

A liquid filter and liquid discharge technology, which is applied in the direction of membrane filter, fixed filter element filter, filtration separation, etc., can solve the problems of complicated filter manufacturing and assembly, and achieve the effect of preventing wrong assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

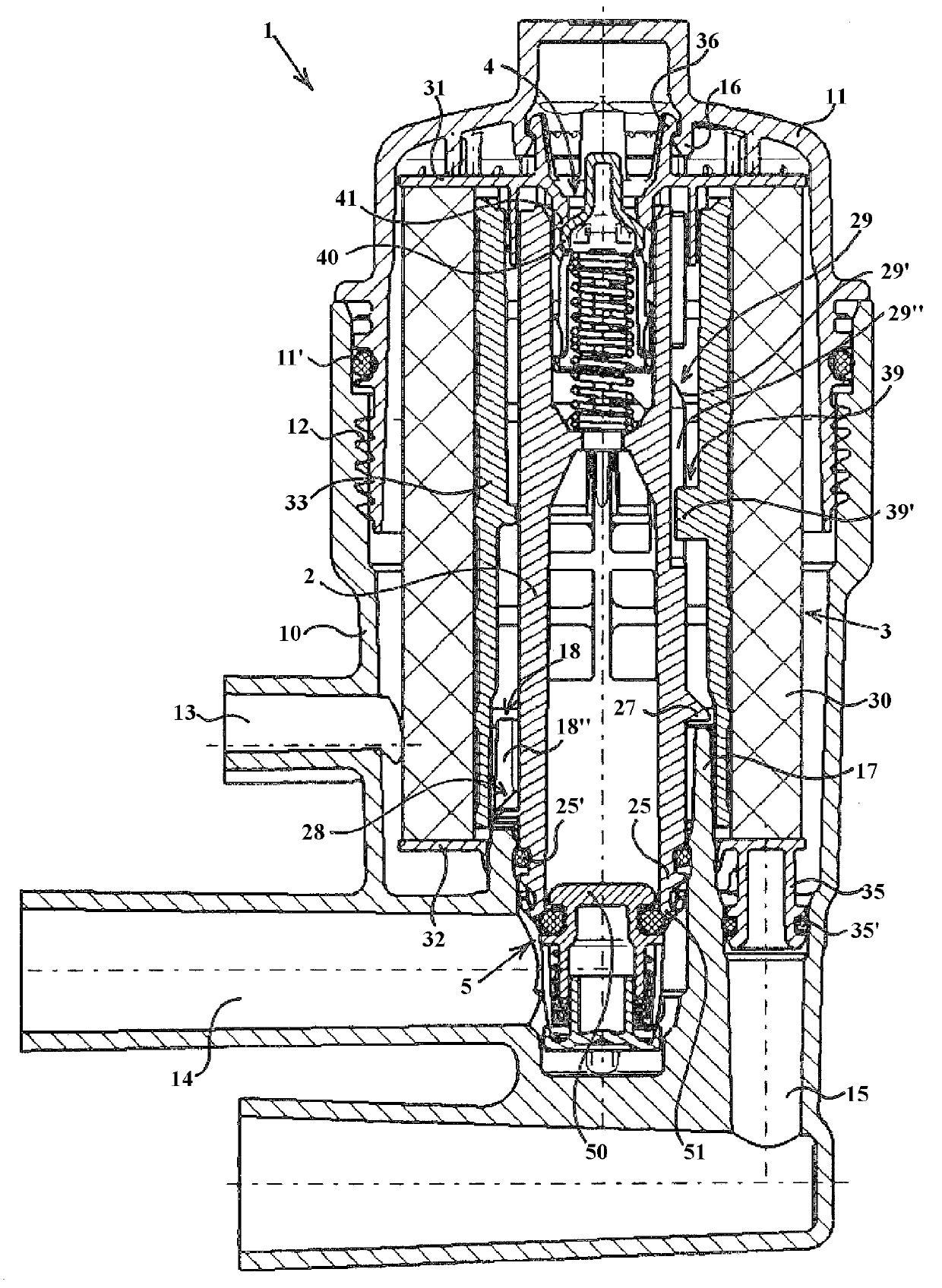

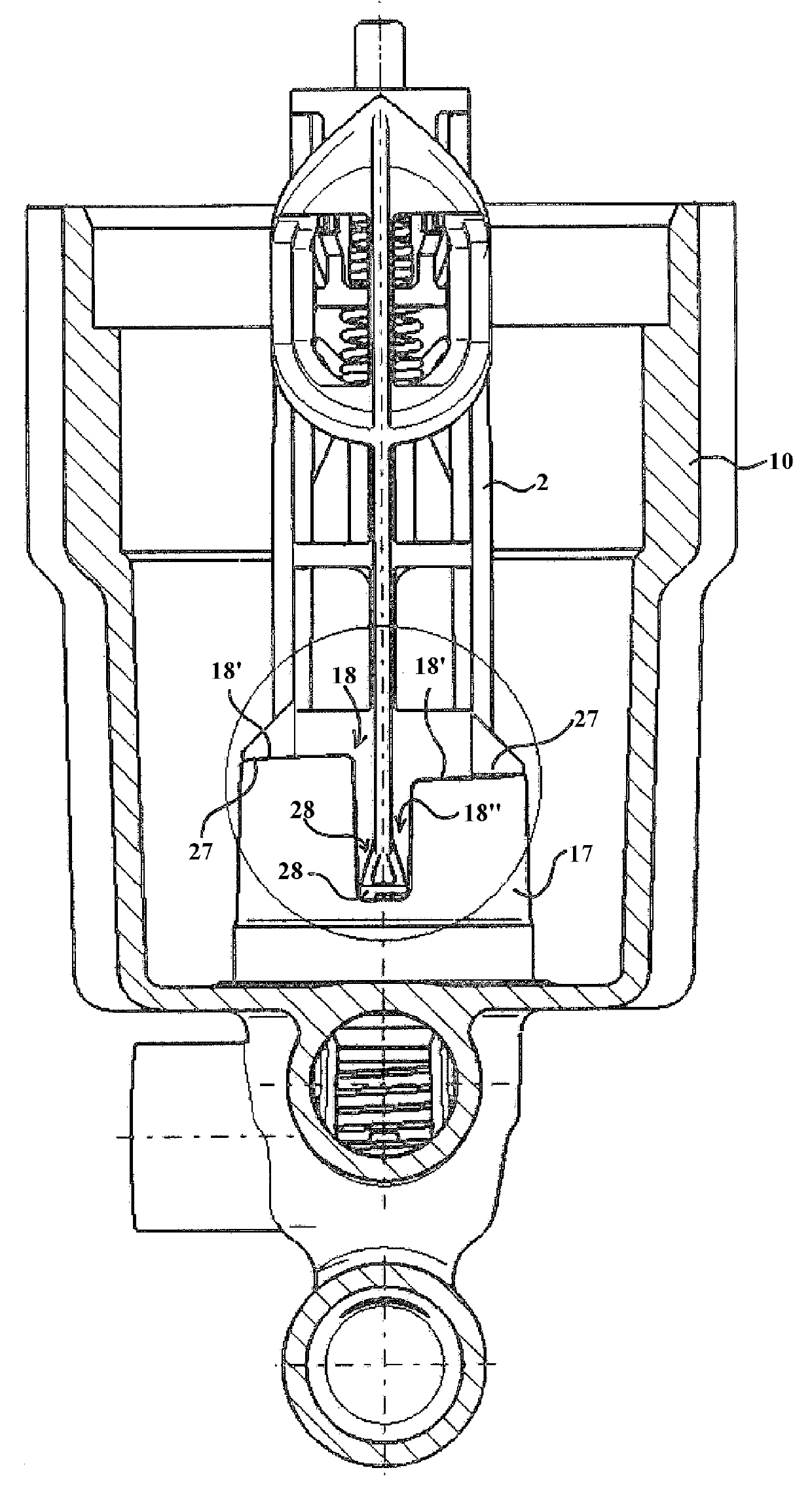

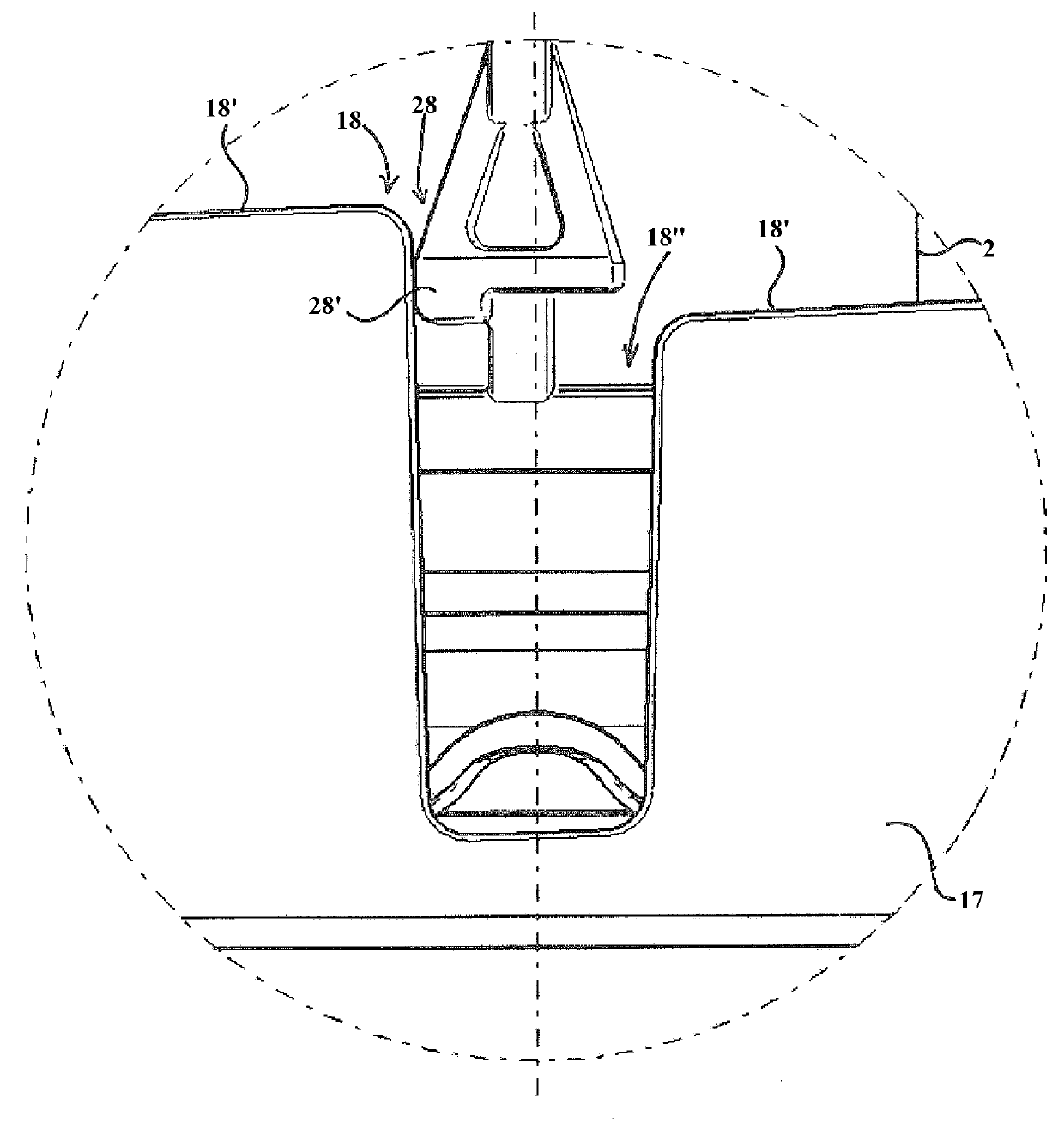

[0040] Attached figure 1 In longitudinal section, a liquid filter 1 , in particular an oil or fuel filter of an internal combustion engine, is shown in its fully assembled state. The liquid filter 1 is designed as an upright filter with a cup-shaped filter housing 10 and an upper screw cap 11 . A filter insert 3 is arranged on the standpipe 2 in the interior of the filter housing 10 . The standpipe 2 is inserted with its lower end 51 sealingly into the socket 17 which is part of the filter housing 10 .

[0041] The filter housing 10 has a raw liquid inlet 13 which here is embodied in the form of a pipe connection and which opens into the filter housing 10 radially from the outside here. Parallel to the raw liquid inlet 13 , offset downwards relative thereto, runs the cleaned liquid outlet 14 , which is likewise designed as a pipe connection and leads radially away from the filter housing 10 . exist figure 1 At the bottom of the filter housing 10 there is arranged a liquid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com