Welding slag cleaner

A technology of remover and welding slag, applied in cleaning methods and utensils, chemical instruments and methods, cleaning methods using tools, etc., can solve the problems of difficult to thoroughly clean the welding torch, unsatisfactory cleaning effect, and difficult to clean the welding torch, etc. Achieve the effect of simple and compact structure, low manufacturing cost, efficient and thorough cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

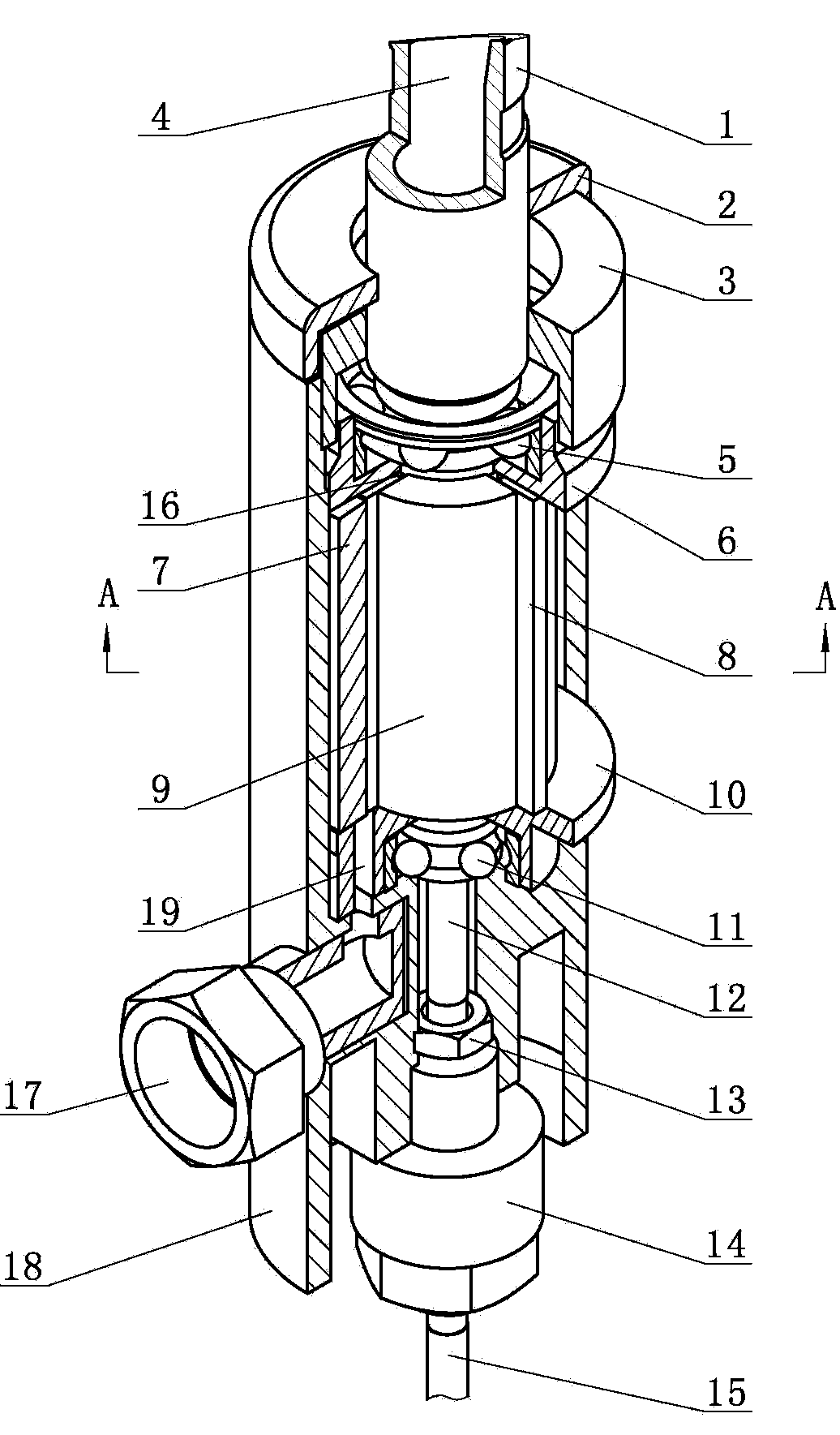

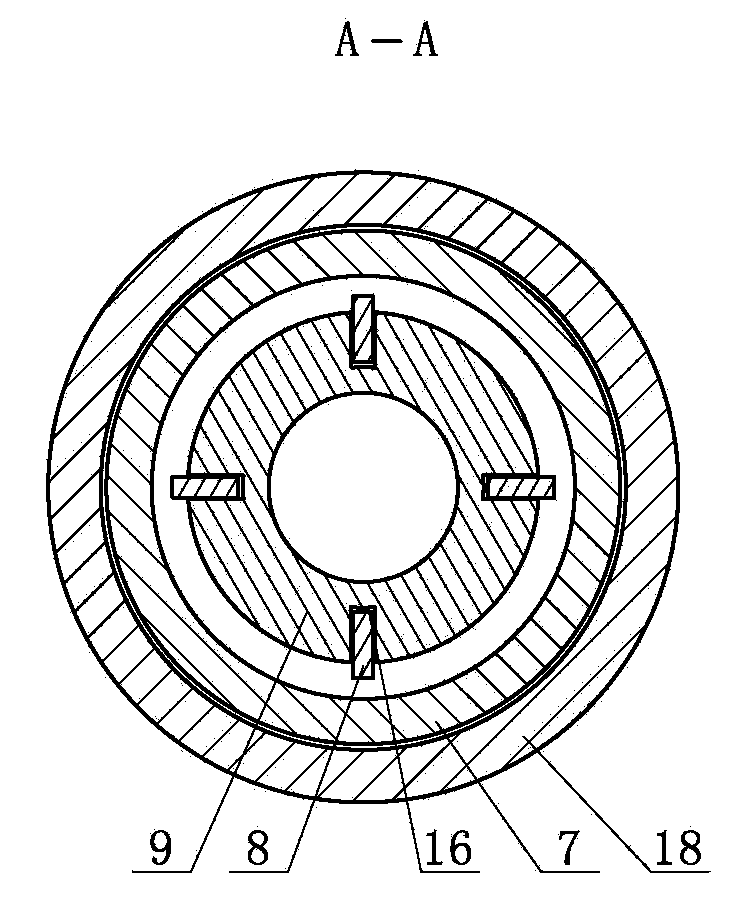

[0009] The welding slag remover of the present invention includes an outer casing. Such as figure 1 As shown, a rotating tube 9 is installed in the outer shell, and the rotating tube 9 can rotate relative to the outer shell. The front end of the rotating tube 9 is equipped with a clear gun rotating head 1, and the rotating tube 9 is located outside the casing. The rear end of the rotating tube 9 is connected with the introducing tube 12, the rotating tube 9 can rotate relative to the introducing tube 12, and the inner cavity of the rotating tube 9 communicates with the introducing tube 12. A driver is installed on the outer shell, and the driver can drive the rotating tube 9 to rotate.

[0010] Before use, earlier lead-in pipe 12 communicates with the container that fills cleaning fluid through flexible pipe. During use, the torch cleaning rotor 1 is first inserted into the welding torch, and the driving mechanism is started. The driving mechanism drives the torch cleaning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com