Combined building brick capable of judging thickness of ladle bath

A combined and masonry technology, used in casting molten material containers, metal processing equipment, casting equipment, etc., can solve problems such as the inability to accurately judge the erosion degree of ladle masonry bricks, the large error of the residual thickness of the ladle, and the lack of identification methods. , to achieve the effect of simple installation, low cost and prevention of safety accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

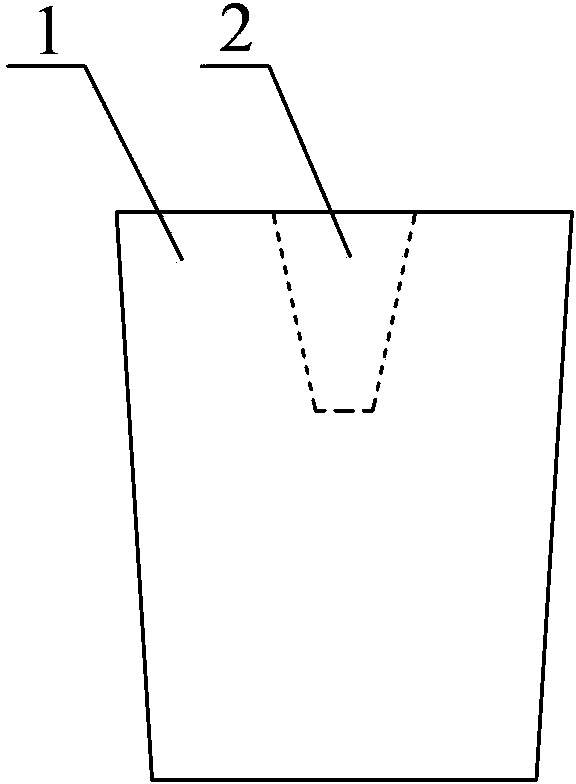

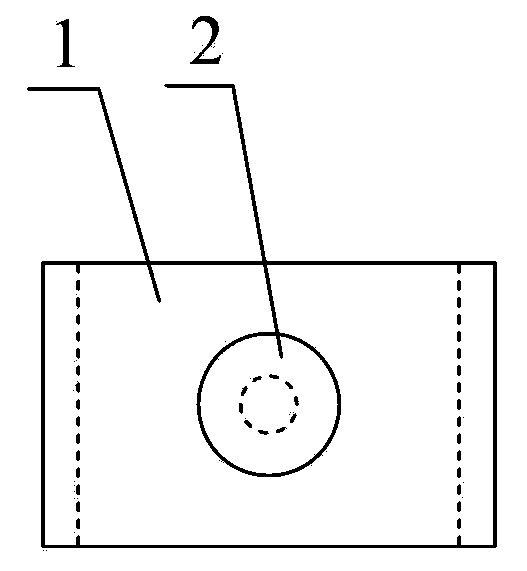

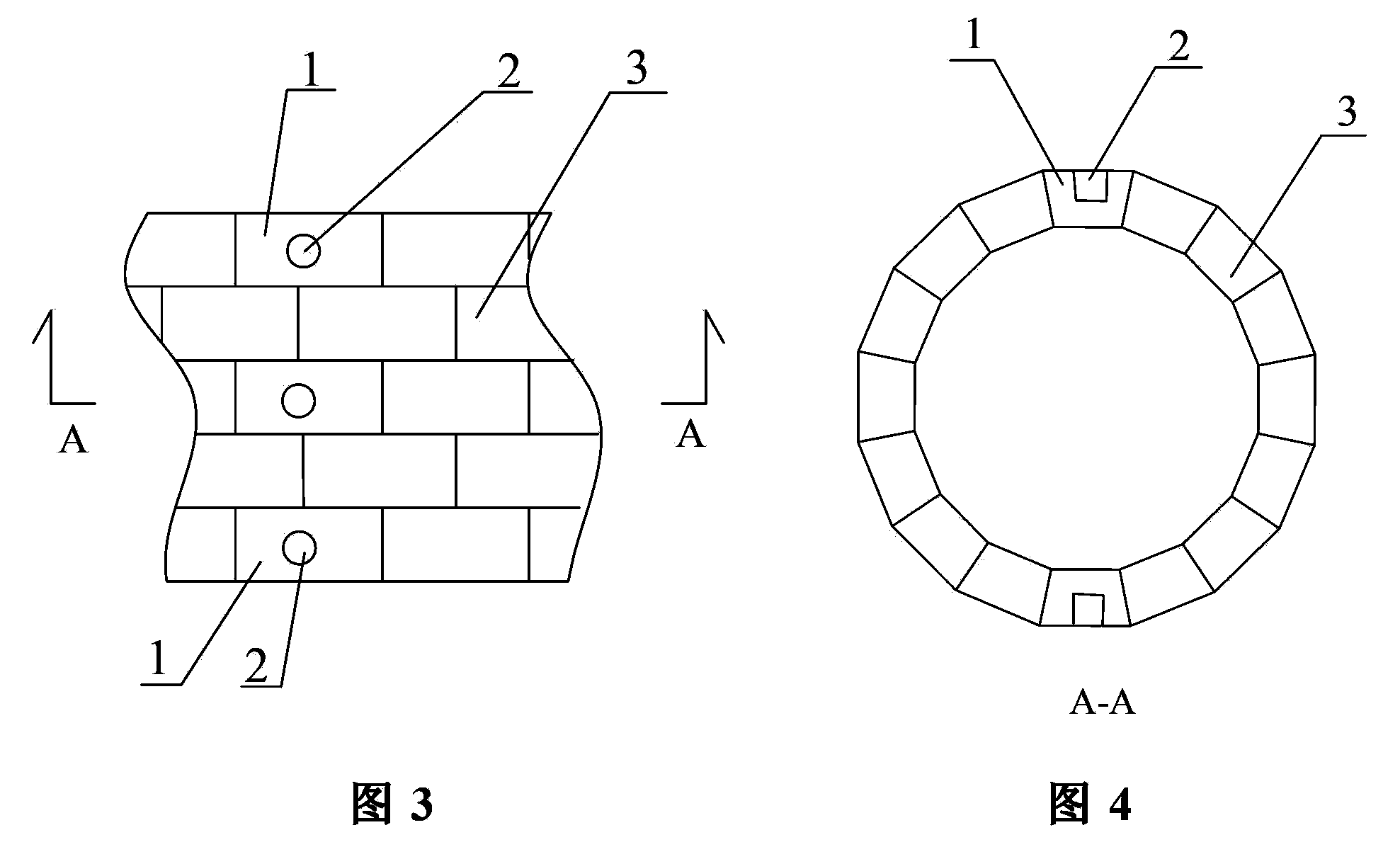

[0015] The combined masonry bricks shown in the figure for judging the thickness of the ladle molten pool include the masonry brick 1 built in the heat insulation wall of the inner wall of the cylindrical ladle. The end of the masonry brick 1 facing the outside of the furnace is provided with a cavity. Logo brick 2 is embedded in it. The sign brick 2 is in the form of a cylinder or a frustum of a cone. The sign brick 2 is a magnesia carbon brick with column length h=70mm. The sign brick 2 is encapsulated in the cavity of the masonry brick 1 through chrome corundum mortar, and the combined masonry brick and the general masonry brick are staggered in the local area of the brick wall 3 to avoid unnecessary waste. Bricks are placed on the eighth, fifteenth, and twenty rings respectively, and 4-6 blocks are evenly placed on each ring. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Column length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com