Warning brick for tundish working lining and preparation method of warning brick

A technology of working lining and tundish, applied in the direction of metal processing equipment, configuration of indicating equipment/measuring equipment, manufacturing tools, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

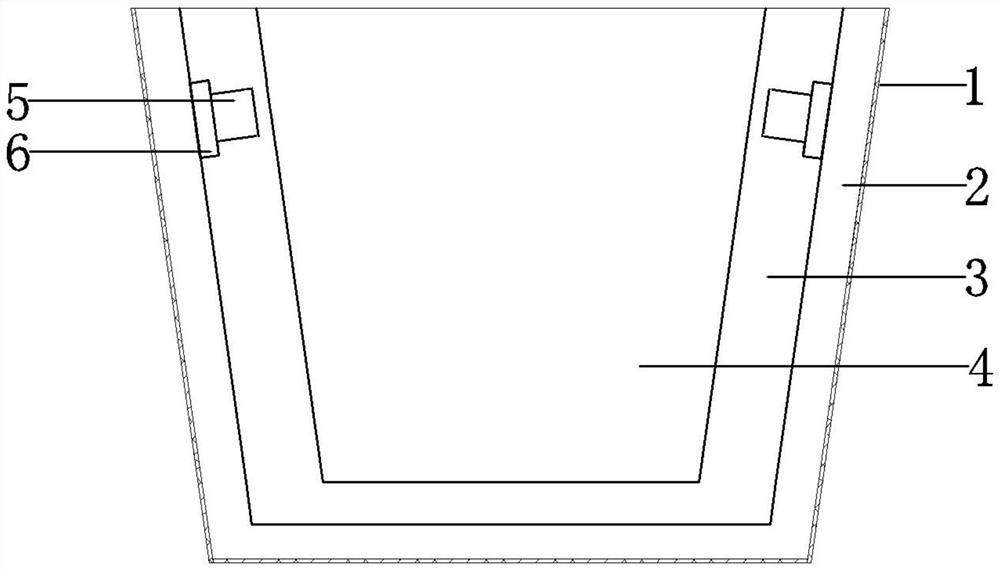

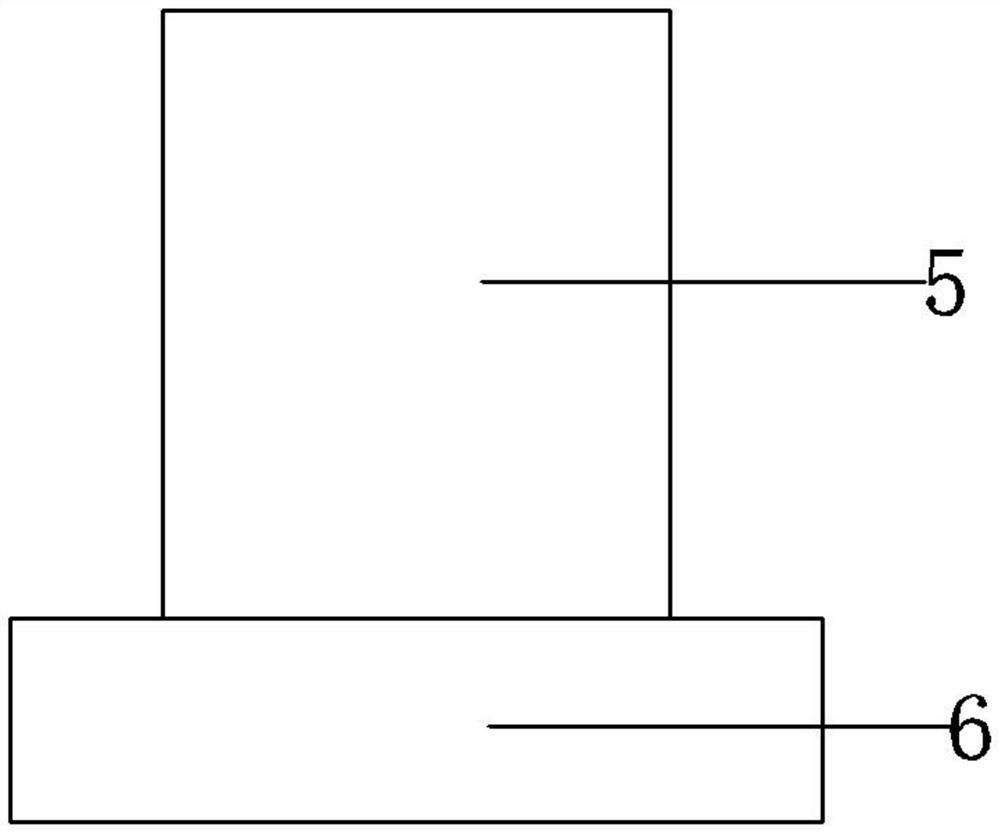

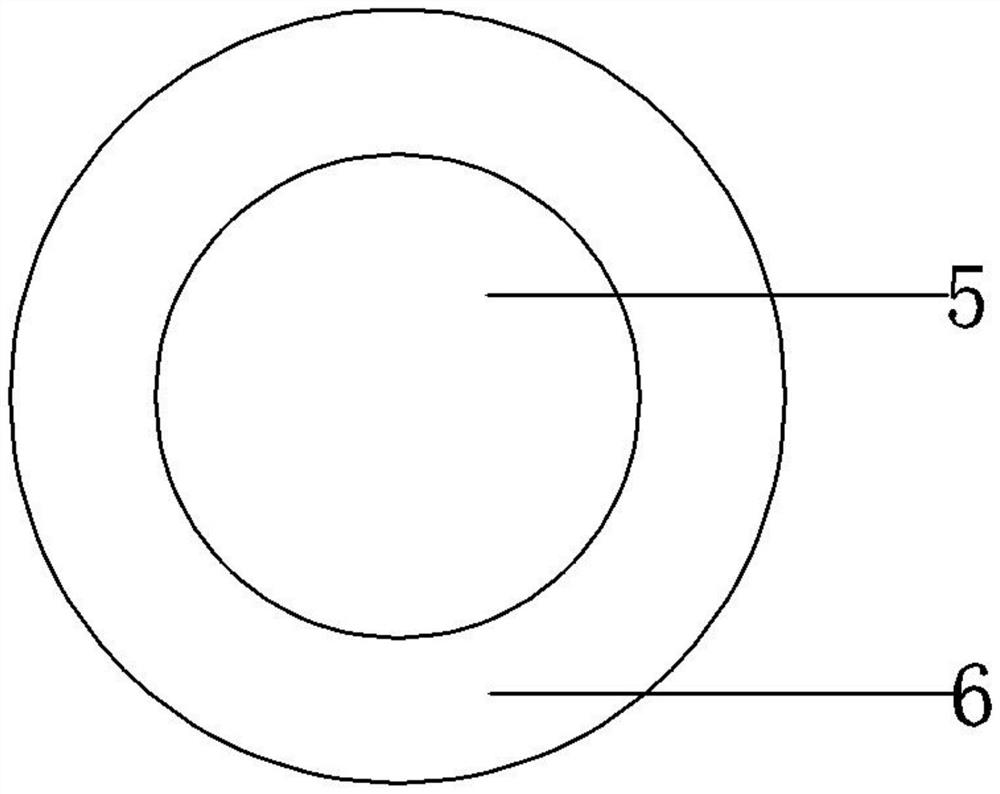

[0026] combine Figure 1 to Figure 3 A warning brick for working lining of tundish is provided, which includes a first brick body and a second brick body. In this embodiment, the first brick body and the second brick body are two sections of cylindrical brick bodies with different cross-sectional areas, wherein The first brick body is the first brick body 5 of the warning brick, and the second brick body is the second brick body 6 of the warning brick. 5. Fixed connection with the second brick body 6 of the warning brick, the radial dimension of the first brick body 5 of the warning brick is smaller than the radial dimension of the second brick body 6 of the warning brick, and the greater the difference between the two, the center of gravity of the warning brick will be far away from the tundish The inner cavity 4 and the first brick body 5 of the warning brick will be consumed layer by layer during use, and will not fall directly as a whole due to an unstable center of gravit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com