High-speed steel electrode blank horizontal continuous casting producing method

A technology of horizontal continuous casting and production method, applied in the field of iron and steel metallurgy, can solve the problems of rising production costs, waste, and discontinuous production, and achieve the effects of improving productivity, reducing related costs, and ensuring continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

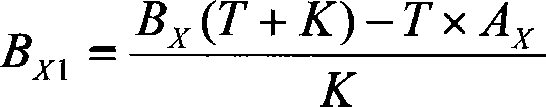

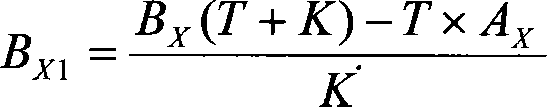

[0010] The technical solution of the present invention is: in the continuous casting process, set the Nth steel as A steel, 1≤N≤6, and the tapping temperature of the last ladle of molten steel added in the continuous casting is 60% higher than its liquidus temperature ~70°C, the weight of the molten steel in the tundish is at least T tons when the continuous casting works normally; assuming that the N+1th type of steel is B steel, the weight of the first batch of molten steel for smelting B steel is K tons, and the composition is according to B X 1 = B X ( T + K ) - T × A X K control, the formula B X1 is the mass percentage content of element X in ...

Embodiment 2

[0012] 1) At the end of the continuous casting of the first type of steel (W9Mo3Cr4V steel), the tapping temperature of the molten steel is 1640 °C, and the tundish heating device is working at the same time; the weight of the molten steel in the tundish is at least 1.0-1.1 tons when the continuous casting is working normally;

[0013] 2) Continuous casting of the second type of steel (W6Mo5Cr4V2 steel) for the smelting of the first batch of molten steel is 3 tons, the content control of each component is shown in the table below, and the tapping temperature is 1630°C; The temperature is 1620°C;

[0014] element

C

W

Mo

Cr

V

mn

Si

First heat, %

0.86

5.10

5.65

4.10

2.10

0.23

0.30

Second furnace, %

0.85

6.10

5.00

4.10

1.95

0.30

0.30

[0015] 3) When the first type of steel (W9Mo3Cr4V steel) is continuously cast to 1.0-1.1 tons, inject the first molte...

Embodiment 3

[0019] 1) At the end of the continuous casting of the first type of steel (W6Mo5Cr4V2 steel), the tapping temperature of molten steel is 1630°C, and the tundish heating device is working at the same time; the weight of molten steel in the tundish is at least 1.0-1.1 tons when the continuous casting is working normally;

[0020] 2) The second type of steel (W4Mo3Cr4VSi steel) is smelted with 3 tons of molten steel in the first heat, and the content control of each component is shown in the table below, and the tapping temperature is 1640°C; 1630°C;

[0021] element

C

W

Mo

Cr

V

mn

Si

[0022] First heat, %

0.95

3.30

2.33

4.10

1.35

0.30

0.90

Second furnace, %

0.93

4.00

3.00

4.10

1.50

0.30

0.75

[0023] 3) When the first type of steel (W6Mo5Cr4V2 steel) is continuously cast to 1.0-1.1 tons, inject the first heat of molten steel of the second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com