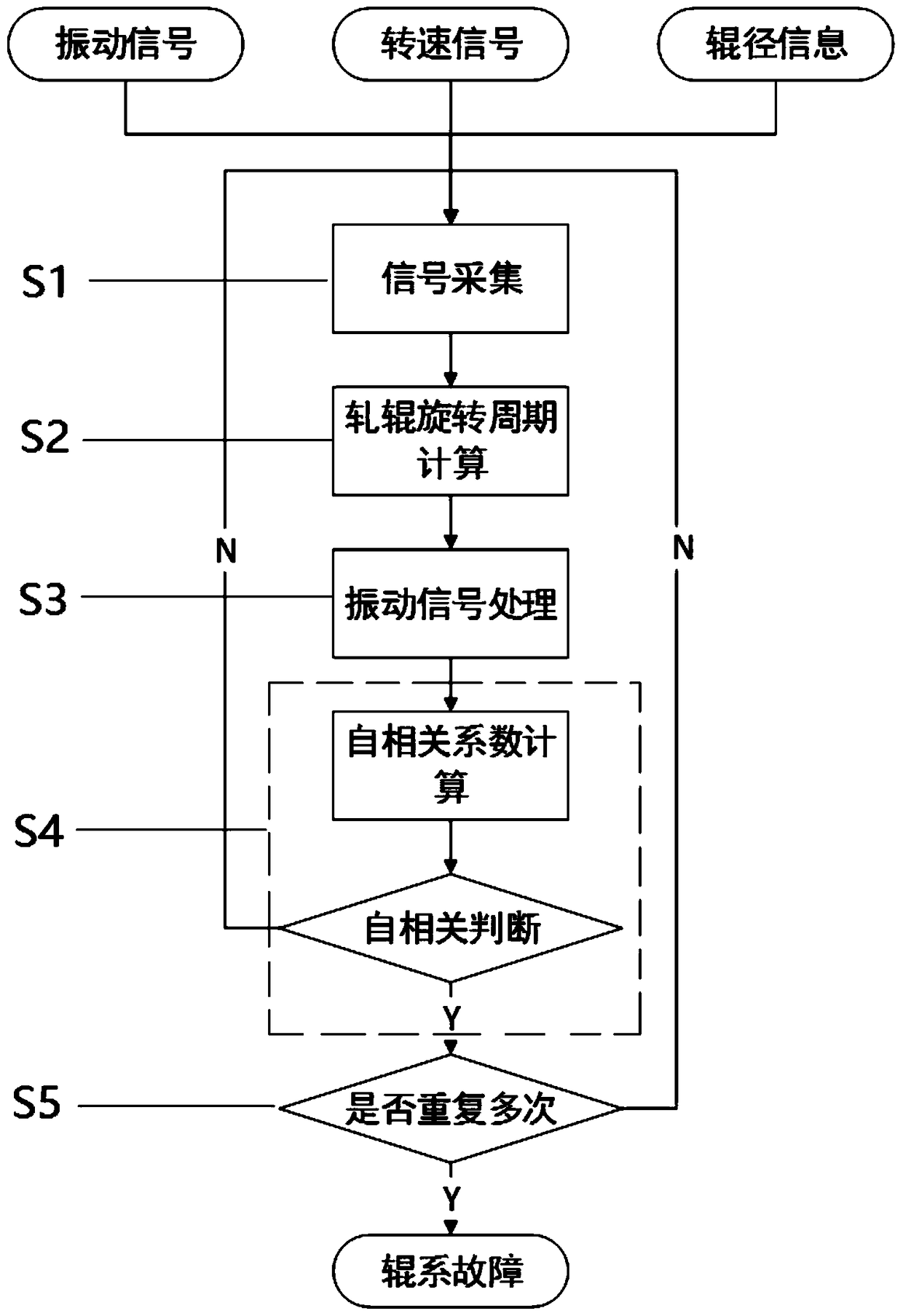

Automatic judgment method and system for rolling mill roll system faults based on signal autocorrelation

An autocorrelation and automatic judgment technology, applied in the direction of metal rolling, metal rolling, and keeping roll equipment in an effective state, can solve the problem of finding roll system faults, unable to accurately diagnose roll system faults, and not proposing a vibration signal method and other problems, to achieve the effect of eliminating dependence, reasonable roll changing time, and avoiding major production accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

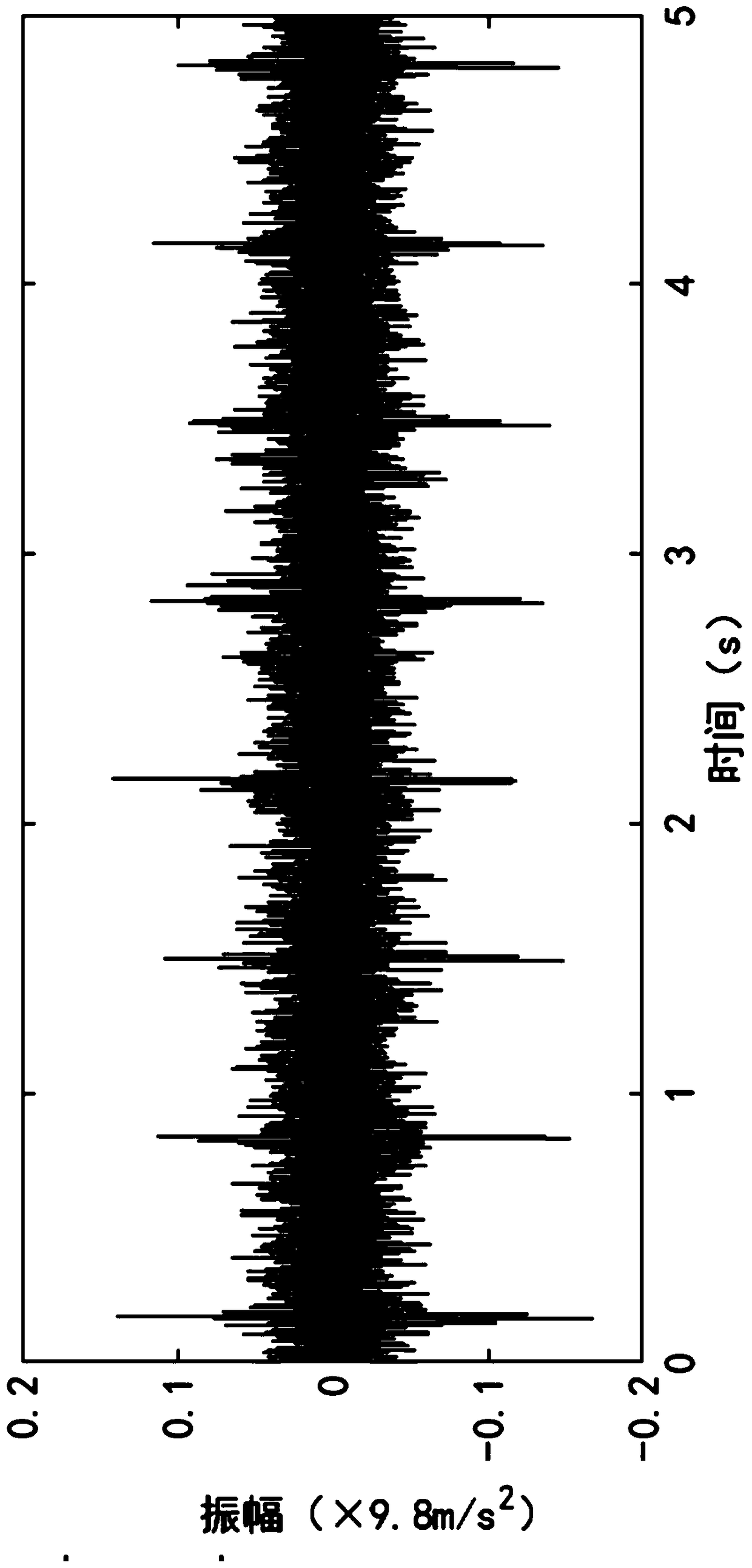

[0051] It is known that to monitor the vibration of the three stands of a six-high five-rolling mill, the vibration waveform data collected by the vibration sensor are as follows: figure 2 As shown, the sampling frequency of the collected vibration signal is 3072Hz, and the main motor speed v of the rolling mill at this moment 3 is 355rpm, the reference value R is set to 0.7, and the reduction ratio of the gearbox is n 3 is 0.77, using work roll transmission, the work roll diameter d 31 About 460.6mm, middle roller diameter d 32 About 528.6mm, support roller diameter d 33 It is about 1382.6mm. Since there is not much difference in the diameter of the upper and lower rolls, it is only distinguished according to the roll type. The roll diameter information is the average diameter of the upper and lower rolls of the same roll type.

[0052] According to the motor speed, gearbox reduction ratio and roll diameter information, the rotation period of each type of roll is calculat...

Embodiment 2

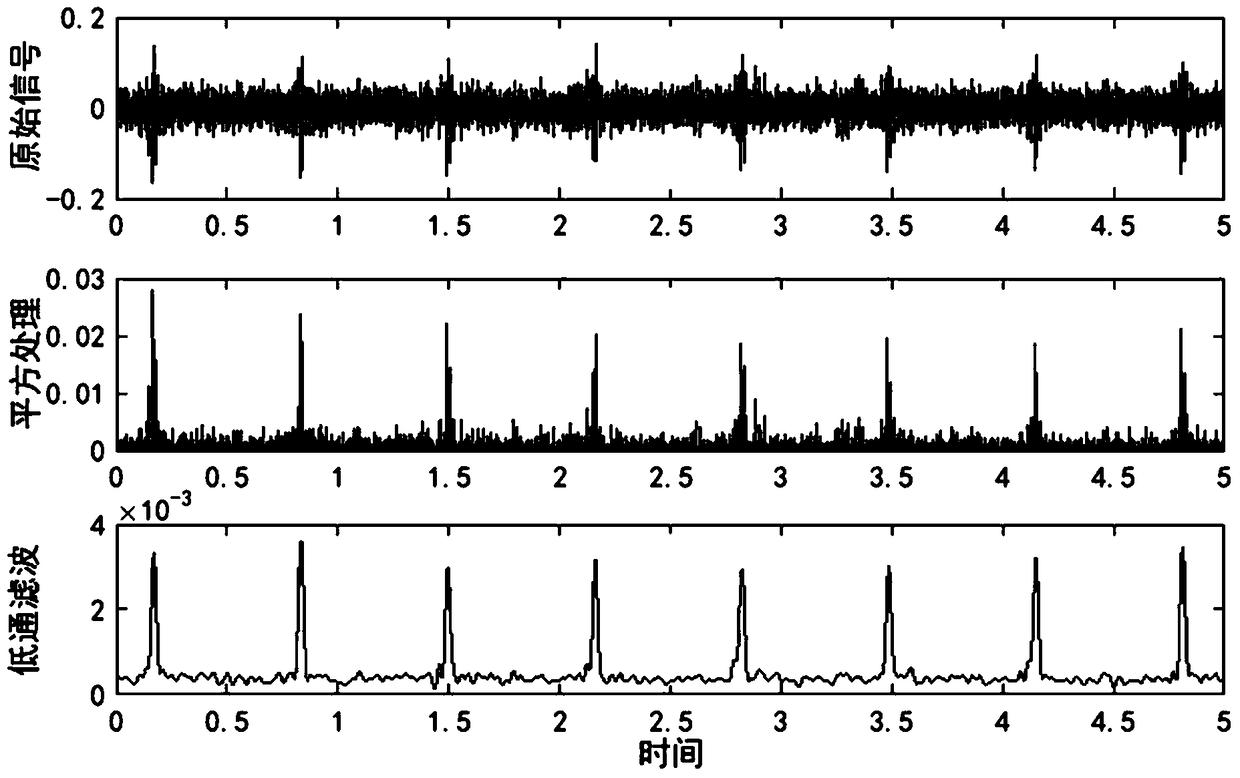

[0071] It is known that the six-stand vibration of a six-high seven-tandem rolling mill under normal operating conditions is monitored, and the collected signals are Figure 5 As shown, this is also the vibration information collected most of the time. The signal is similar to noise without any characteristic information. Next, the method of the present invention is used to analyze and judge the signal, and the accuracy of the method of the present invention is verified again.

[0072] Concrete calculation process can refer to embodiment 1, Figure 6 It is the waveform comparison diagram before and after the square processing and filtering processing. After the processing is completed, it is still a random waveform. The correlation coefficient is calculated after time-shifting according to different roll cycles respectively, and the following is obtained:

[0073] R 31 =0.0063,R 32 =0.0556,R 33 = 0.0226.

[0074] The correlation degree between the rotation period of each r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com