LED (Light Emitting Diode) light source with low voltage and energy saving

A LED light source and low-voltage technology, applied in the field of LED light source, can solve the problems of assembly structure limitation, poor environmental adaptability, heat dissipation structure, etc., and achieve the effect of reducing processing difficulty, reducing application environment requirements, and good safety performance

Inactive Publication Date: 2011-06-15

薛金海

View PDF8 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The present invention aims to provide a low-voltage energy-saving LED light source to solve the problems of poor safety, poor applicability, poor environmental adaptability, high cost, need for heat dissipation structure, limited assembly structure, and short overall life in the prior art.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

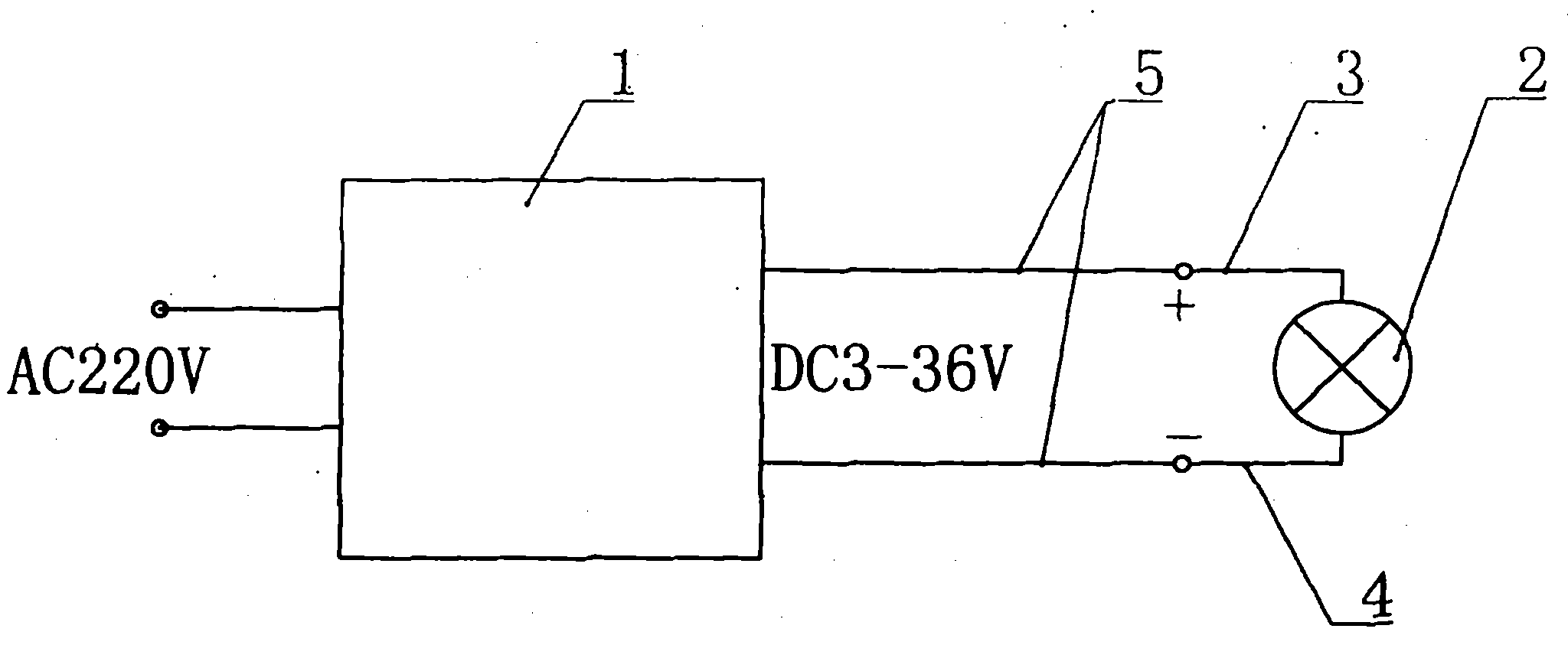

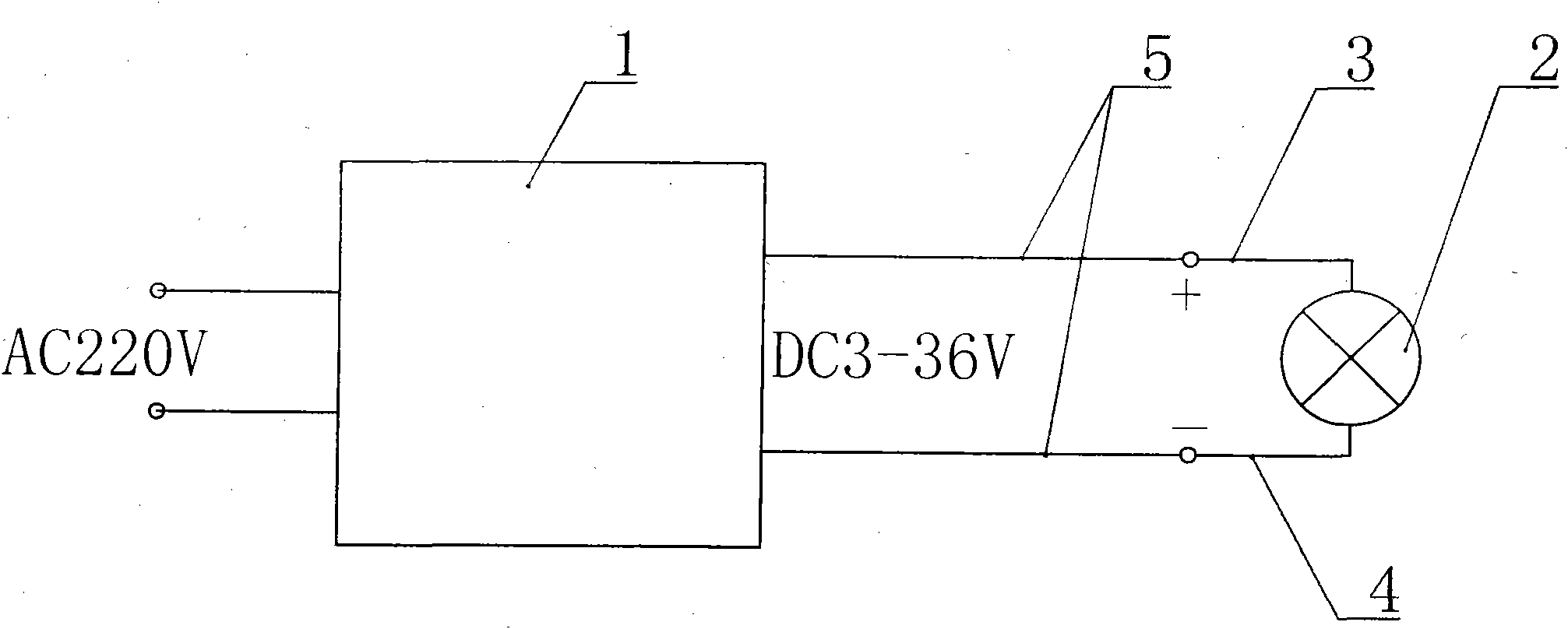

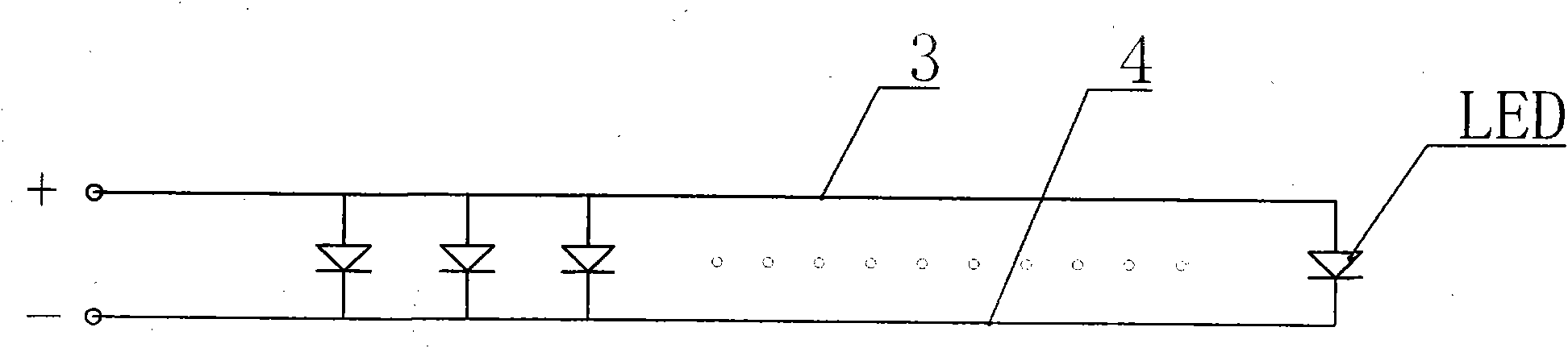

The invention relates to an LED (Light Emitting Diode) light source with low voltage and energy saving, which comprises a power supply converter and a light emitting body, wherein the power supply converter and the light emitting body are in a split structure; the direct current output of the power supply converter has safe voltage, and the power supply converter is at least correspondingly connected with the positive and negative electrodes of the light emitting body through wires; the light emitting body is formed by connecting a copper-clad plate and multiple paths of LEDs with high brightness in parallel; the LEDs are welded on the copper-clad plate; and the number of each path of the LEDs in series is 1-12. The LED light source provided by the invention has the advantages that a part of the light emitting body has low safe voltage and good safety performance; an accumulator or a wind power or solar energy power supply can be used as a power supply, and the application range is wide; because the light emitting body does not contain the high voltage of a mains supply, the requirements for an application environment are greatly lowered, and the light emitting body can be used indoors and outdoors, thereby greatly expanding the application occasions of the light emitting body; the power supply converter and the light emitting body are independently arranged, and one power supply converter can be configured with multiple light emitting bodies, thereby lowering the cost of the power supply converter; the general assembly structure of the light emitting body is simplified; and the light emitting body is fully utilized in the service life range, thereby lowering the service cost.

Description

Low-voltage energy-saving LED light source technical field The invention relates to an LED light source, in particular to a low-voltage energy-saving LED light source, which can be used as lighting and motor vehicle lighting or signal lights, such as indoor and outdoor lighting, and lighting in special environments such as high humidity and underwater. Background technique In order to use the mains power supply in the existing LED light source, a switching power supply is assembled on the luminous body, and the mains power (AC220V) is stepped down and converted into a DC power supply, that is, the luminous body (LED) and the switching power supply are combined into one, and directly connected to the market. electrical connection. Although this structure is convenient to use, it has the following disadvantages: 1. Poor safety: the luminous body (including switching power supply) is directly connected to the mains, and there are potential safety hazards during installation...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): F21S9/03F21S9/04F21V23/06F21Y101/02F21Y115/10

CPCY02B20/72

Inventor 薛金海

Owner 薛金海

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com