Shock absorption bottom fork of motorcycle

A technology for motorcycles and flat forks, applied in motorcycles, motor vehicles, bicycles, etc., can solve problems such as deformation of shock-absorbing support plates, and achieve the effect of not easily deformed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention.

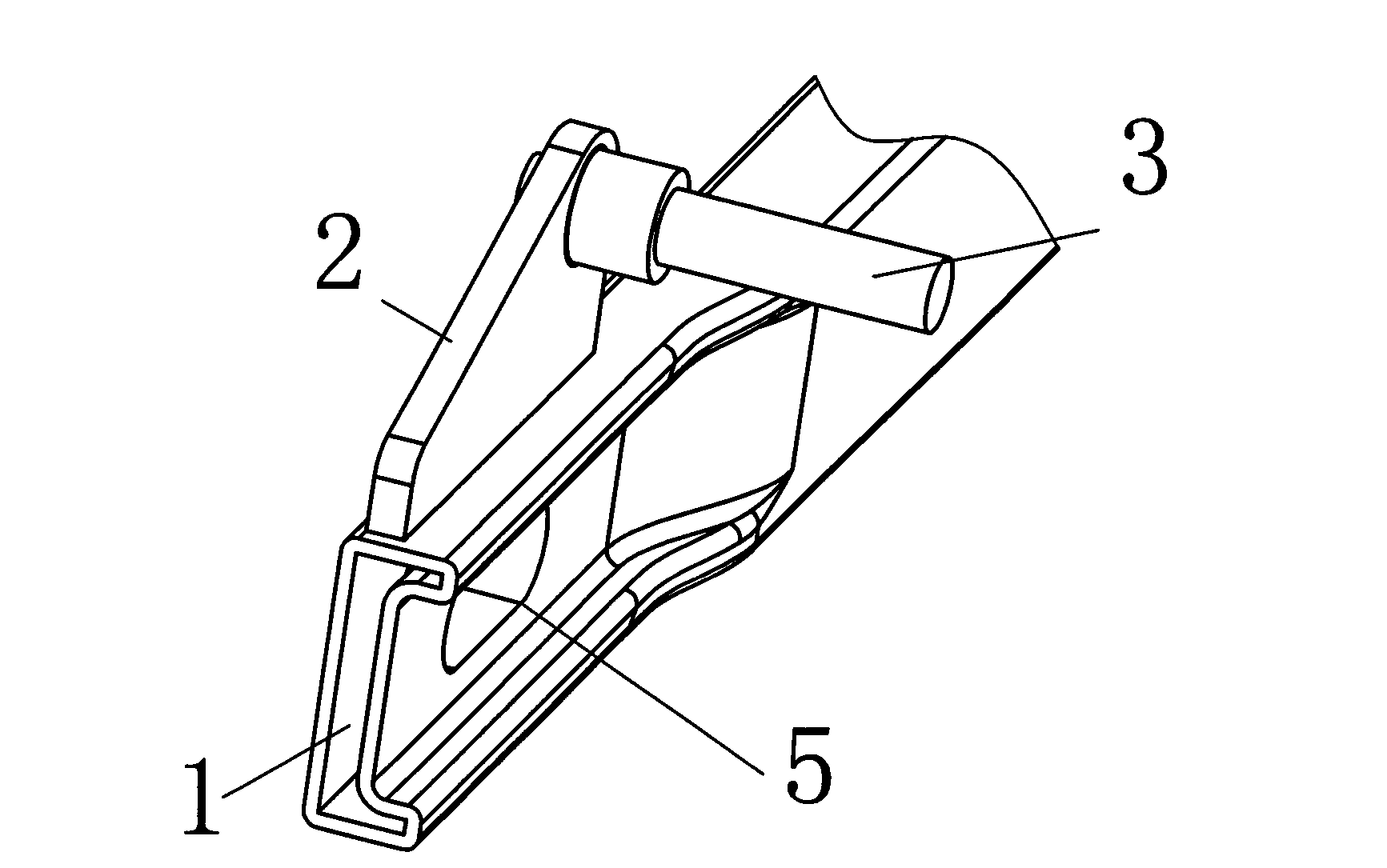

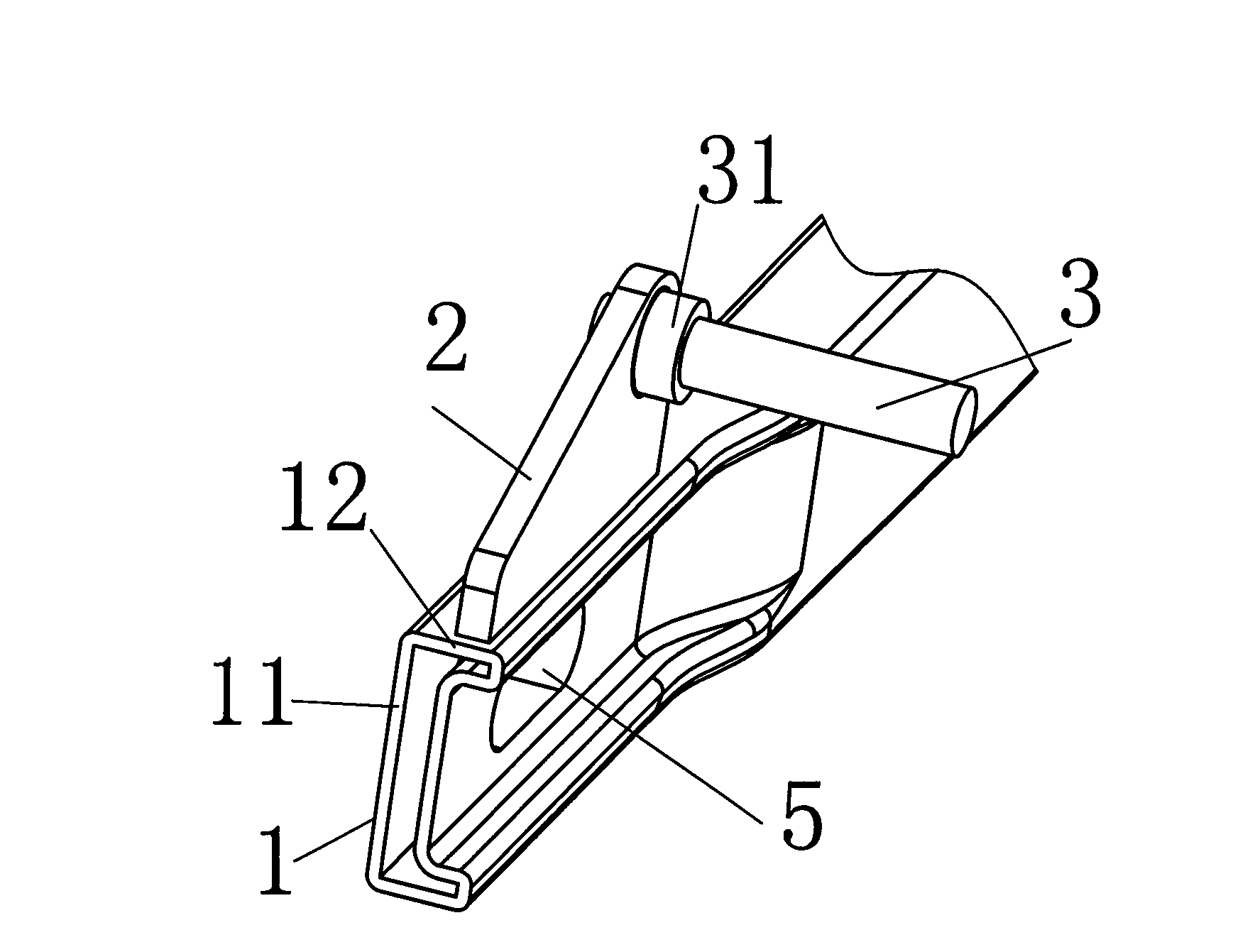

[0011] See attached figure 2 , the shock-absorbing flat fork of motorcycle of the present invention, it comprises flat fork tube 1, and flat fork tube axle mounting hole 5 positions are stamped and formed into hollow channel steel form, and the web 11 of channel steel form is positioned at inner side, and wheel shaft is processed on web 11 Mounting hole 5, the upper wing plate 12 of the channel steel form is welded with shock-absorbing support plate 2, and the shock-absorbing support plate 2 is parallel to wheel shaft mounting hole 5 and is provided with the shock-absorbing shaft 3 of the cantilever, and the shock-absorbing shaft 3 is a st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com