Adjustable transfer box

A kind of turnover box, adjustable technology, applied in the direction of internal accessories, etc., can solve the problems of increased collision damage probability of goods, inability to change the volume size, non-standard stacking of turnover boxes, etc., to achieve long service life, light weight and easy operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

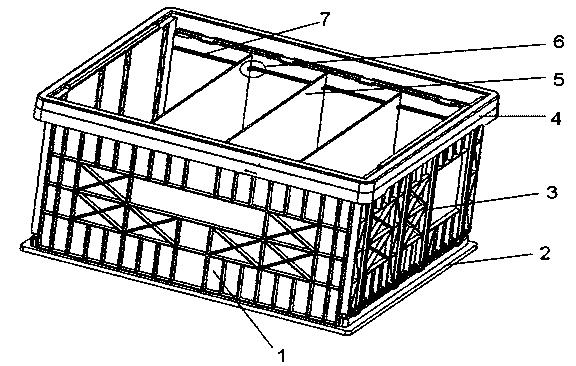

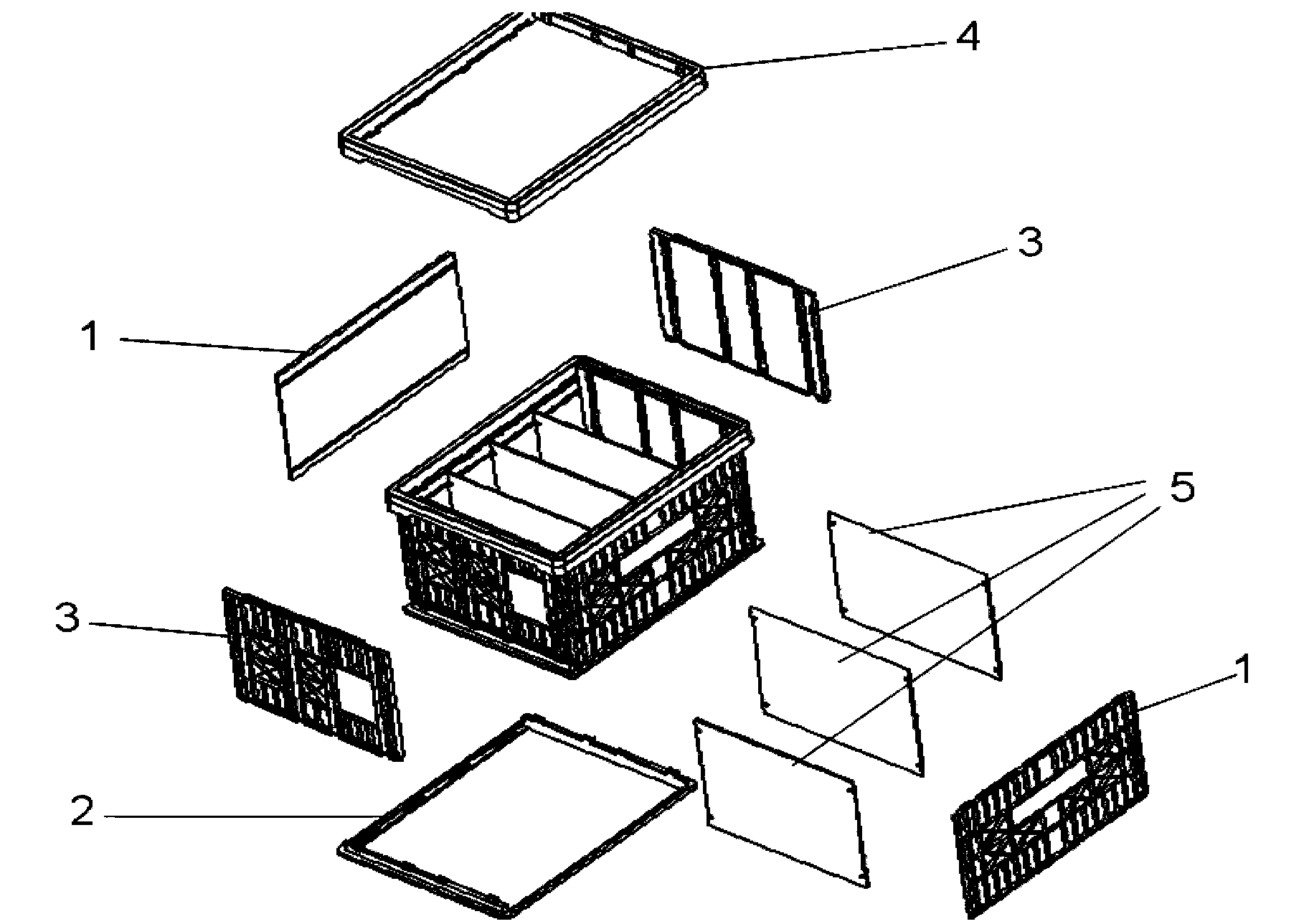

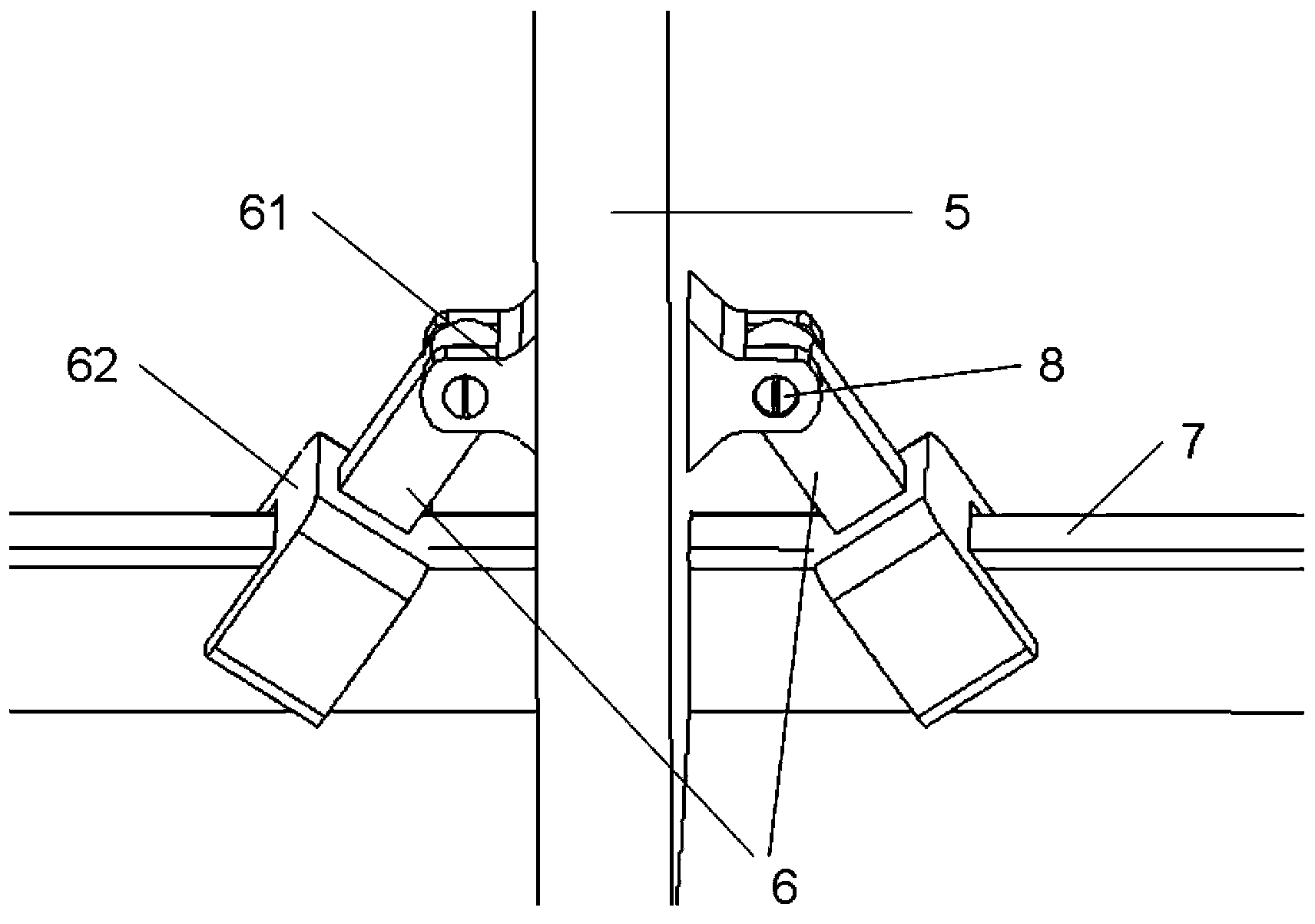

[0029] as attached Figure 6 As shown, the turnover box body of the present invention is spliced by a base plate 2, two long side plates 1, two short side plates 3, an upper fixing plate 4 and a guide sliding partition 5. The bottom ends of the long side plates and short side plates are provided with pin holes, which can be linked with the pin holes of the base plate through the pins, and then fixed on the base plate; the upper ends of the long side plates and short side plates are fixed on the upper fixing plate in the same way. The upper and lower sides of the long side plate 1 are respectively provided with a convex guide slide bar 7; the four corners of the guide slide partition plate 5 are provided with a concave groove 51 and a limit block 6, wherein the concave groove 51 (such as Figure 5 As shown) is well matched with the convex guide bar 7 on the long side plate 1, the limit block 6 includes a connecting piece 61 and a clamp 62, the connecting piece 61 is fixed on ...

Embodiment 2

[0031] as attached Figure 7 As shown, the turnover box body of the present invention is spliced by a base plate 2, two long side plates 1, two short side plates 3, an upper fixing plate 4 and two guide sliding partitions 5. A convex guide bar 7 is respectively arranged on the upper and lower sides of the long side plate; concave grooves and limit blocks 6 are arranged on the four corners of the guide sliding partition, wherein concave grooves 51 (such as Figure 5 (shown) fits well with the convex guide slide on the long side plate, and the limit block fixed on the guide slide partition rotates in an arc along the fixed axis and falls onto the convex guide slide, and is aligned with the convex guide slide to form a snap (such as image 3 ), so as to fix the two guide sliding partitions inside the turnover box. In this embodiment, the inner space of the turnover box can be divided into three parts. In the embodiment, the material of the box body and the guide sliding parti...

Embodiment 3

[0033] as attached figure 1 , 2 As shown, the turnover box body of the present invention is spliced by a base plate 2, two long side plates 1, two short side plates 3, an upper fixing plate 4 and three guide sliding partitions 5. A convex guide bar 7 is respectively arranged on the upper and lower sides of the long side plate; concave grooves and limit blocks 6 are arranged on the four corners of the guide sliding partition, wherein concave grooves 51 (such as Figure 5 (shown) fits well with the convex guide slide on the long side plate, and the limit block fixed on the guide slide partition rotates in an arc along the rotating shaft 8 and falls onto the convex guide slide, and is aligned with the convex guide slide to form a snap (such as image 3 ), so as to fix the three guide sliding partitions inside the turnover box. In this embodiment, the inner space of the turnover box can be divided into four parts. In the embodiment, the material of the box body and the guide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com