Ring plate positioning and reinforcing device applied to DTM169 spinning frame

A technology of DTM169 and reinforcing device, which is applied in the direction of textiles and papermaking, etc., can solve problems such as the displacement of lifting beams, steel rings, spindles, leaf plate centers, etc., to improve product quality, reduce spun yarn breakage, and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

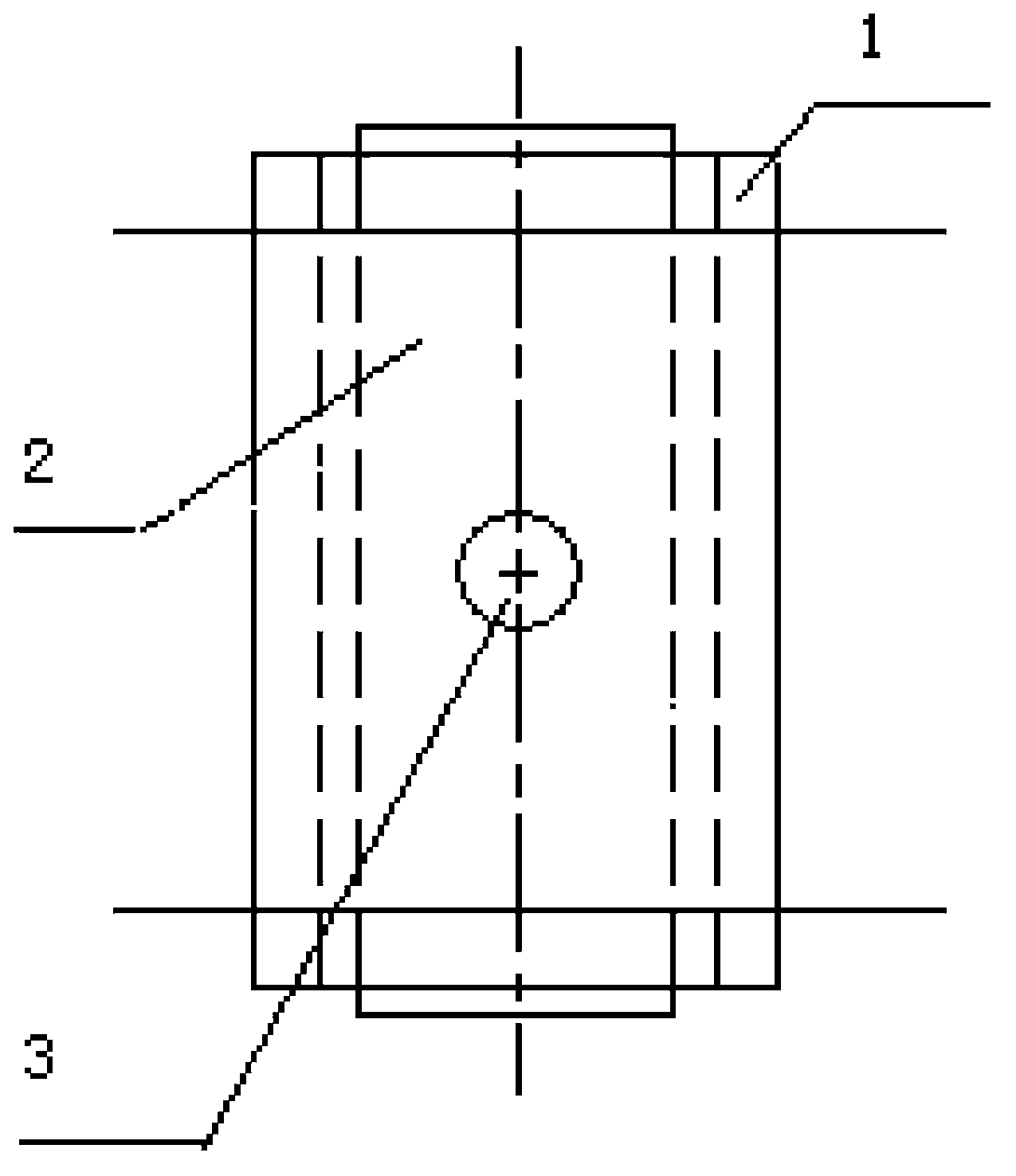

[0008] With reference to the accompanying drawings, the present invention installs a fixed plate 1 on the original DTM169 type spinning frame ring plate lifting beam, the fixed plate is longitudinally provided with a reinforcement cavity 2, and the pulling belt is loaded into the reinforcement cavity; The positioning pin holes 3 corresponding to the apertures of the suspenders, the bolts pass through the positioning pin holes and the apertures to fix the fixing plate on the crossbeam.

[0009] The fixed plate 1 is a cuboid iron block with a length of 25mm, a width of 25mm and a thickness of 40mm. The fixing plate is longitudinally provided with a reinforcement cavity 2 with a length of 15 mm, a width of 11 mm, and a height of 40 mm, and the horizontal positioning pin hole 3 is a hole of ∮6.5 mm.

[0010] In the present invention, a fixed plate 1 is added to the lifting beam 4 of the ring plate of the DTM169 spinning frame, and the sling is loaded into the reinforcement cavity ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com