compressor

A compressor and crankshaft technology, applied in the field of compressors, can solve the problems of reducing the strength of the crankshaft 1 and failing to clean the root

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

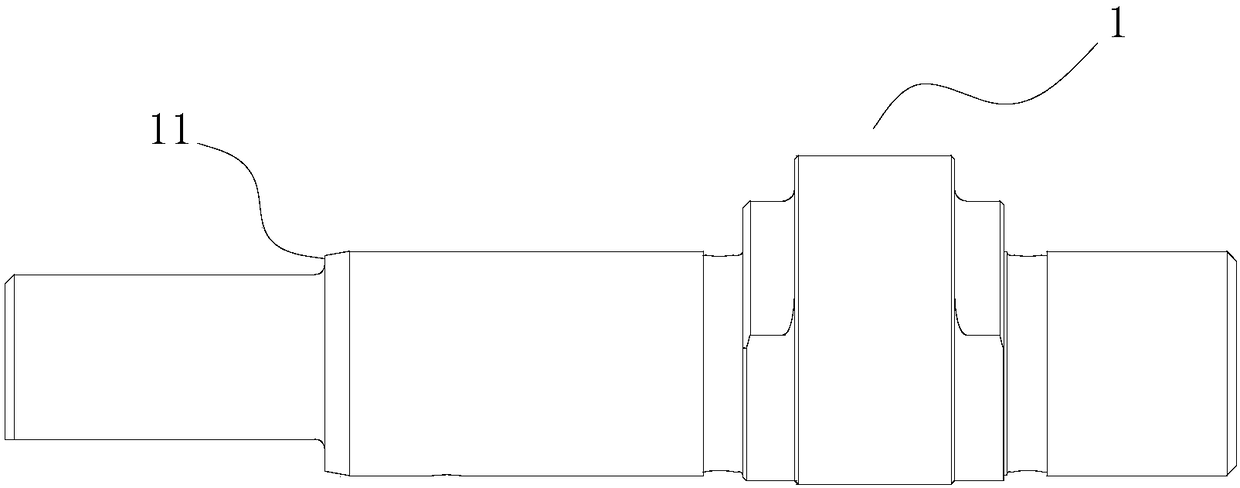

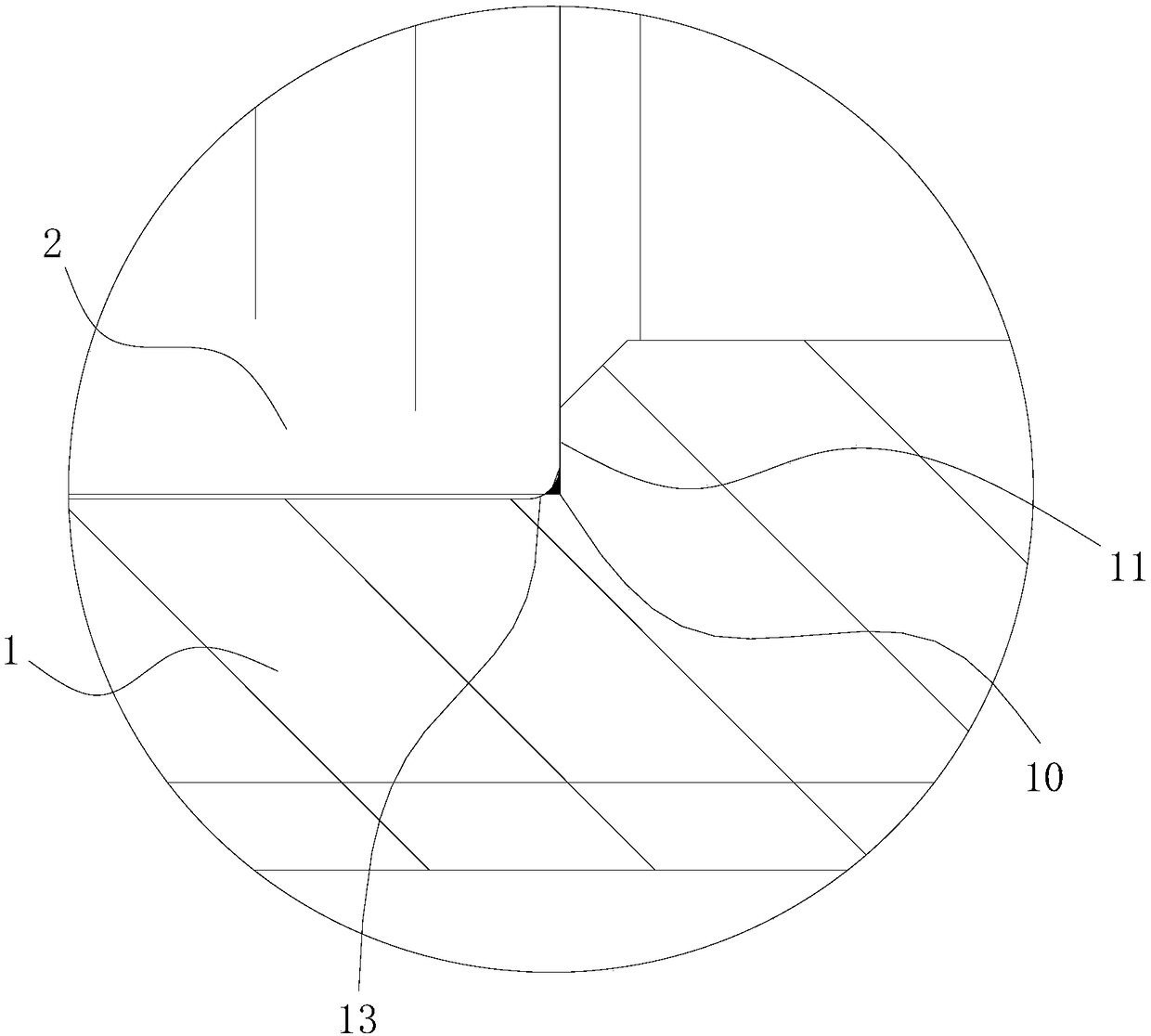

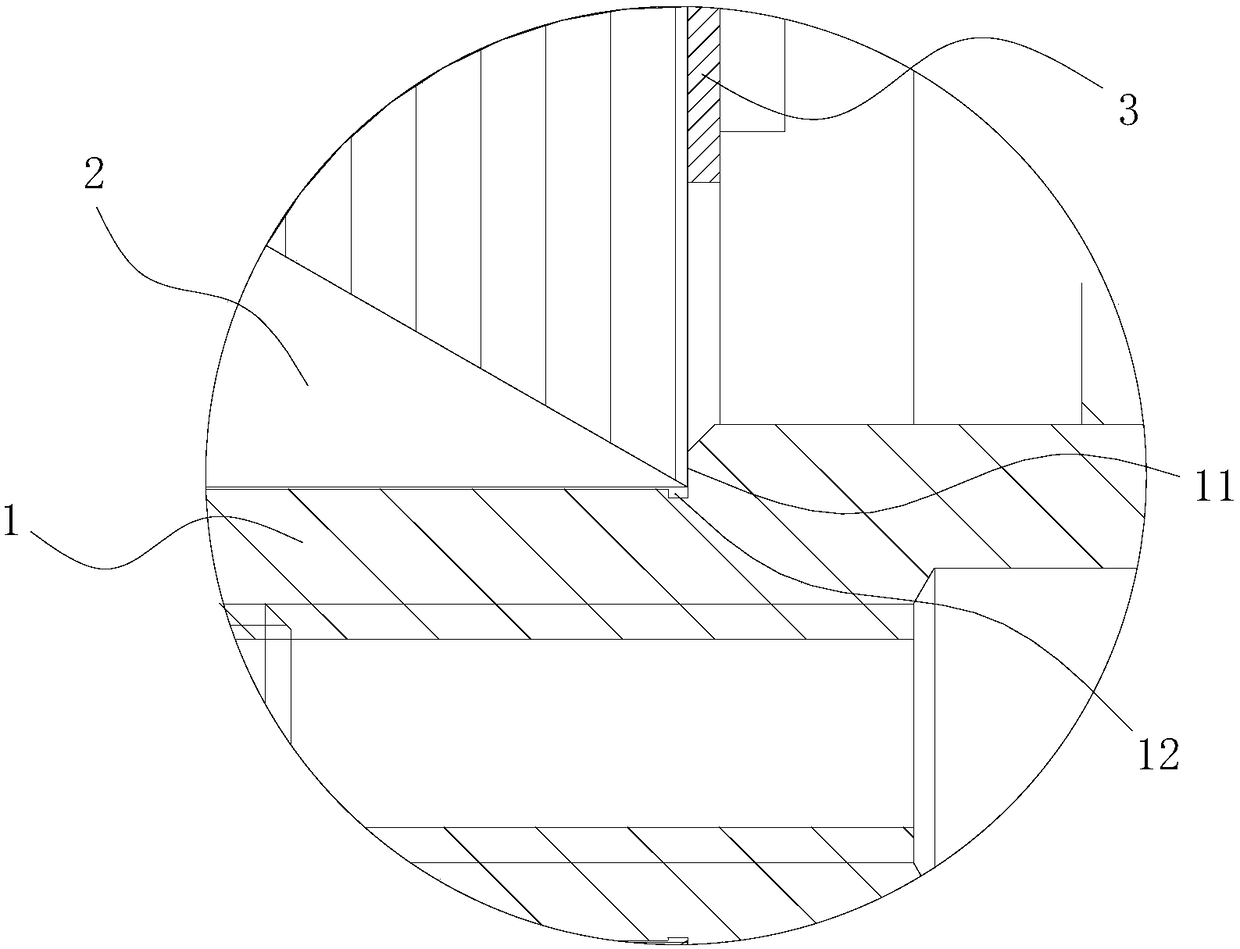

[0029] The preferred embodiment discloses a compressor. Such as Figure 4 and Figure 5 As shown, the compressor includes a crankshaft 1, a rotor core 2 and a sheet-shaped baffle 3. One side of the baffle 3 is attached to the support surface 11 at the trimming position of the long axis of the crankshaft 1, and the other side is attached to the rotor iron core. Core 2 on.

[0030] A baffle 3 is set between the support surface 11 at the long axis trimming position of the crankshaft 1 and the rotor core 2, which solves the problem of the transition between the circular arc and the straight line connection of the rotor core 2 and the crankshaft 1 in the existing structure. If the problem of interference occurs, it is ensured that the rotor core 2 will not tilt after assembly and will not affect the coaxiality of the stator-rotor.

[0031] The specific structure of the baffle plate 3 is not limited, as long as it can separate the supporting surface 11 of the long axis trimming p...

Embodiment 2

[0040] This preferred embodiment discloses a micro compressor. The micro-compressor includes a crankshaft, a rotor iron core and a sheet-shaped baffle. One side of the baffle is attached to the support surface of the long axis trimming position of the crankshaft, and the other side is attached to the rotor iron core. It solves the problem of interference between the transition fillet and the crankshaft at the connection between the circular arc and the straight line of the rotor iron core in the existing structure, and ensures that the rotor iron core will not tilt after assembly and will not affect the coaxiality of the stator-rotor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com