Slope friction vibration isolation system

A technology of seismic isolation system and inclined plane, which is applied in the direction of earthquake resistance and building components, can solve the problems of frictional sliding pendulum bearing damage, danger of upper device, difficulty in structural reset, etc., and achieve easy construction and manufacturing, easy reset, and reduce overturning damage risk effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

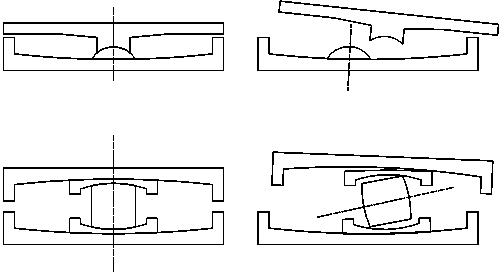

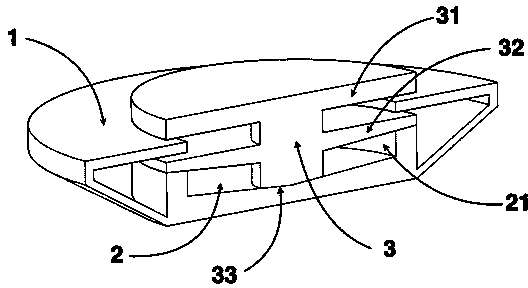

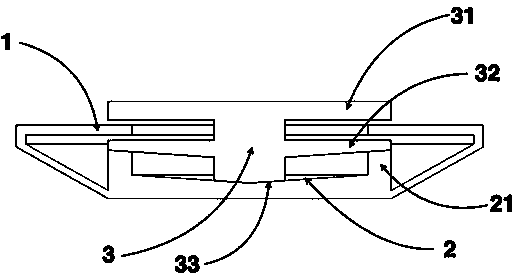

[0019] refer to figure 1 and figure 2 , the slope friction shock isolation system provided in this embodiment includes a baffle 1 , a conical sliding concave surface 2 and a central column 3 that can move between the baffle 1 and the conical sliding concave surface 2 .

[0020] The central column 3 is composed of an upper flange 31 , a lower flange 32 and a conical sliding convex surface 33 . The central column 3 is divided into two layers by the upper flange 31 and the lower flange 32. Its central section is arranged in the shape of "dry" and is combined with the conical sliding convex surface 33. When the vertical vibration of the near-field earthquake is too large and the conical When the conical sliding convex surface 33 is lifted off, the phenomenon that the conical sliding convex surface 33 is thrown out can be reduced, which effectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com