Outdoor rod body construction method

A construction method and rod body technology, which are applied in basic structure engineering, building types, buildings, etc., can solve the problems of the deviation of the verticality of the rod body and the bottom surface, the unguaranteed levelness, the error of the vertical instrument, etc. Simple, effect of increasing contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

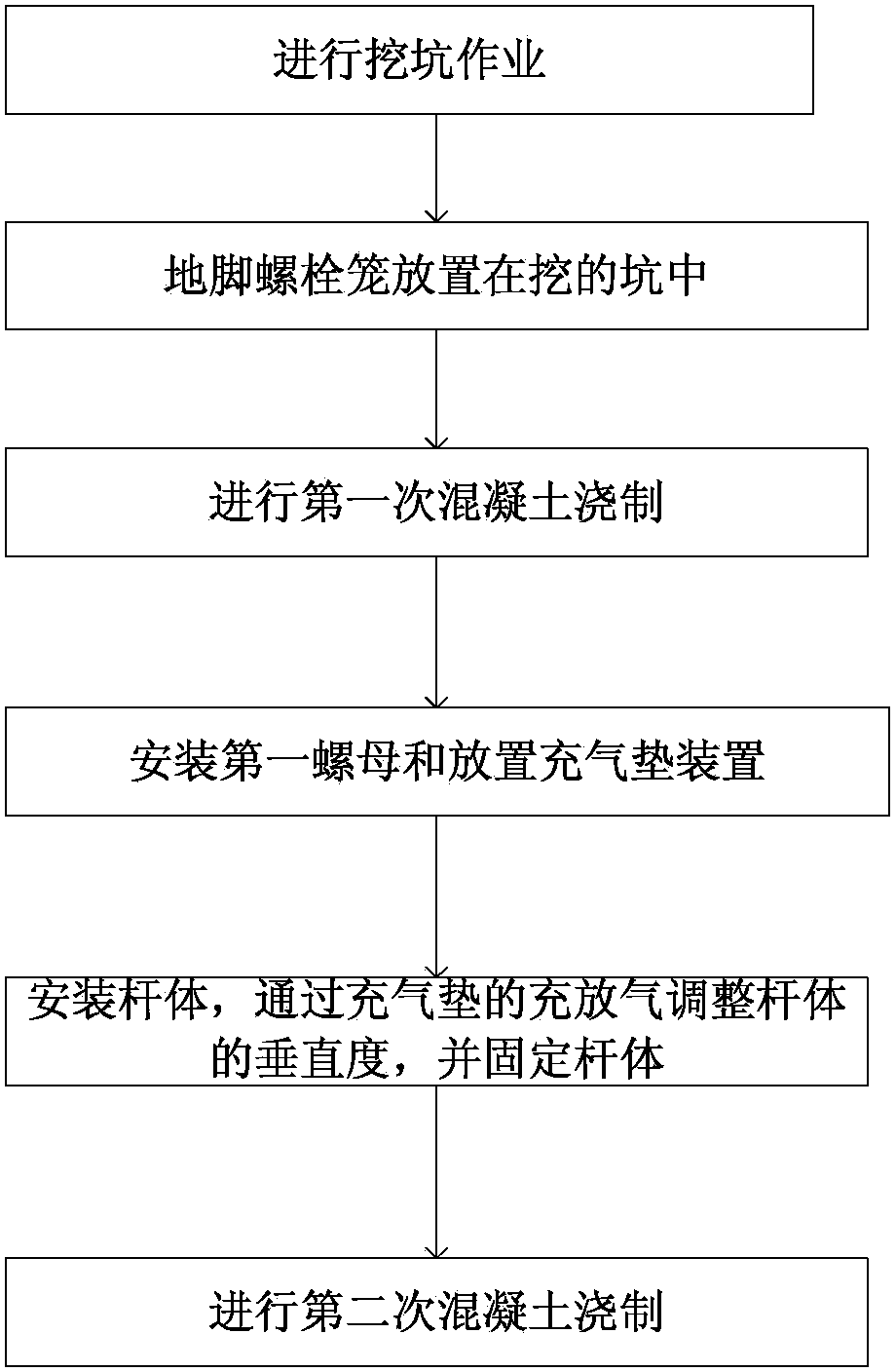

[0024] Such as figure 1 As shown, the present invention provides a kind of outdoor rod body construction method, comprises the following steps:

[0025] Step 1. Excavating pits according to requirements;

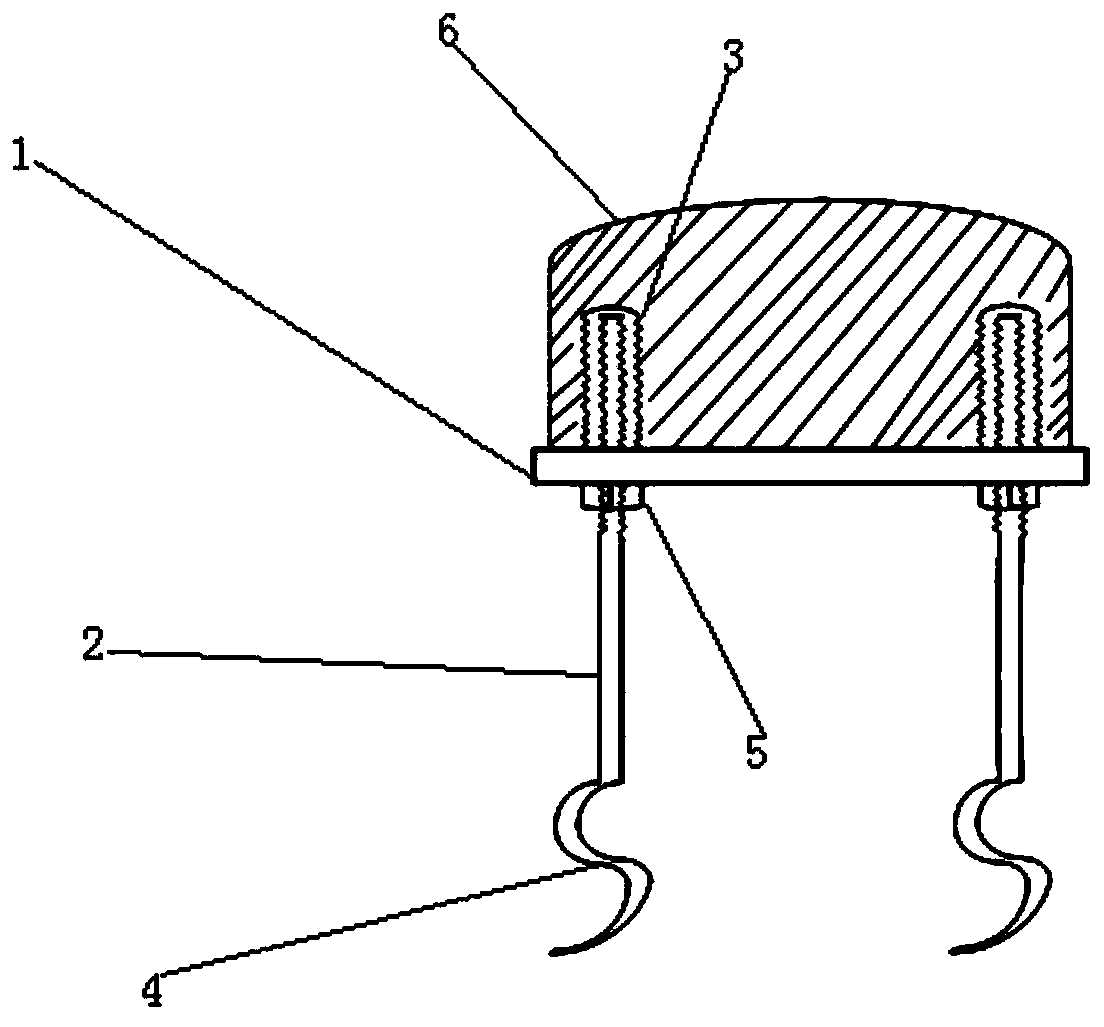

[0026] Step 2. Place the anchor bolt cage consisting of four anchor bolts and the floor flange in the pit described in step 1. The specific structure of the anchor bolt cage is as follows: figure 2 As shown: the bottom flange 1 is provided with four bolt holes penetrating the bottom flange, the upper end of each anchor bolt is provided with a first external thread, and the first external thread A nut 3 is set on the outside and a port of the nut is closed. The inner surface of the nut 3 is provided with an internal thread compatible with the first external thread on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com