EGR tube seal ring

A sealing ring and tube sealing technology, which is applied to the sealing device of the engine, engine components, machines/engines, etc., can solve the problems affecting the efficiency of exhaust gas emission and purification, the discharge of waste into the atmosphere, and environmental impact, so as to reduce pollution and seal Good performance and the effect of improving the efficiency of waste discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The preferred technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

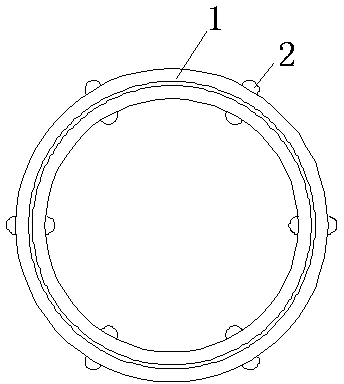

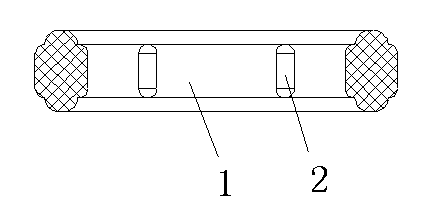

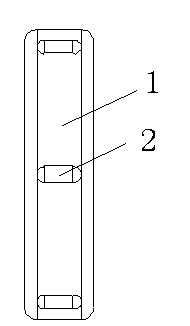

[0012] As shown in the figure, the EGR pipe seal ring of the present invention includes a seal ring body 1, the seal ring body 1 is circular, the cross-sectional area of the seal ring body 1 is a rectangle, and the four corners of the rectangle Chamfers are provided respectively, and pairs of bosses 2 are evenly arranged on the inner and outer walls of the sealing ring body 1, each of the bosses 2 is semi-cylindrical, and both ends are sealed with the seal by a semi-spherical shape. The side walls of the ring body 1 are excessively connected, and the plurality of pairs of bosses 2 are six pairs, which are evenly distributed on the inner and outer walls of the sealing ring body 1 .

[0013] In the EGR pipe sealing ring of the present invention, the rectangular cross-section adopts arc chamfer transition, which is beneficial to ap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com