Movable type cantilever material sampling device

A mobile and sampler technology, applied in the field of movable material samplers, can solve the problems of inconvenient replacement of the sampling head, poor sampling position accuracy, limited rotation angle, etc. The effect of force balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below with reference to the drawings and specific embodiments.

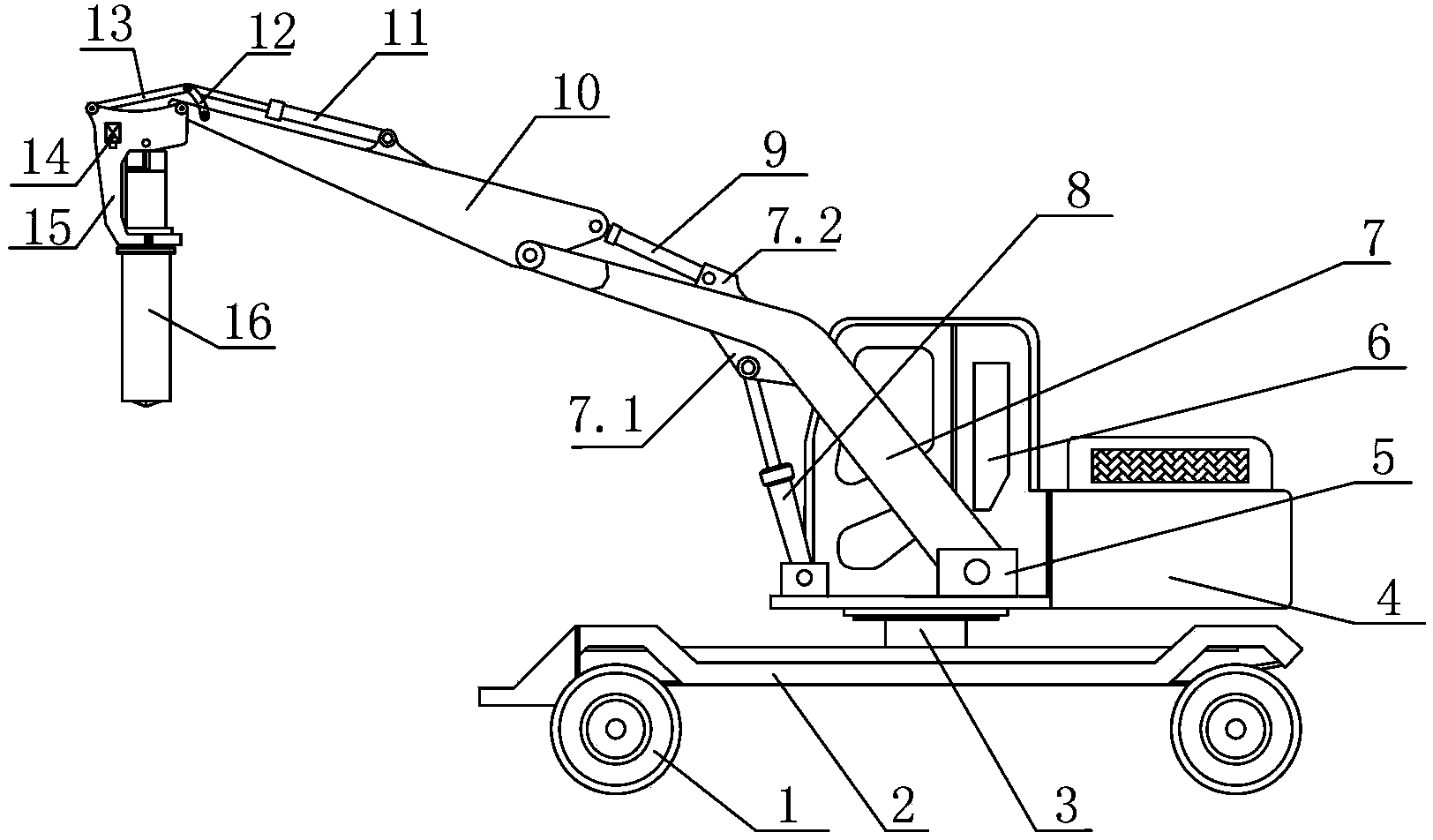

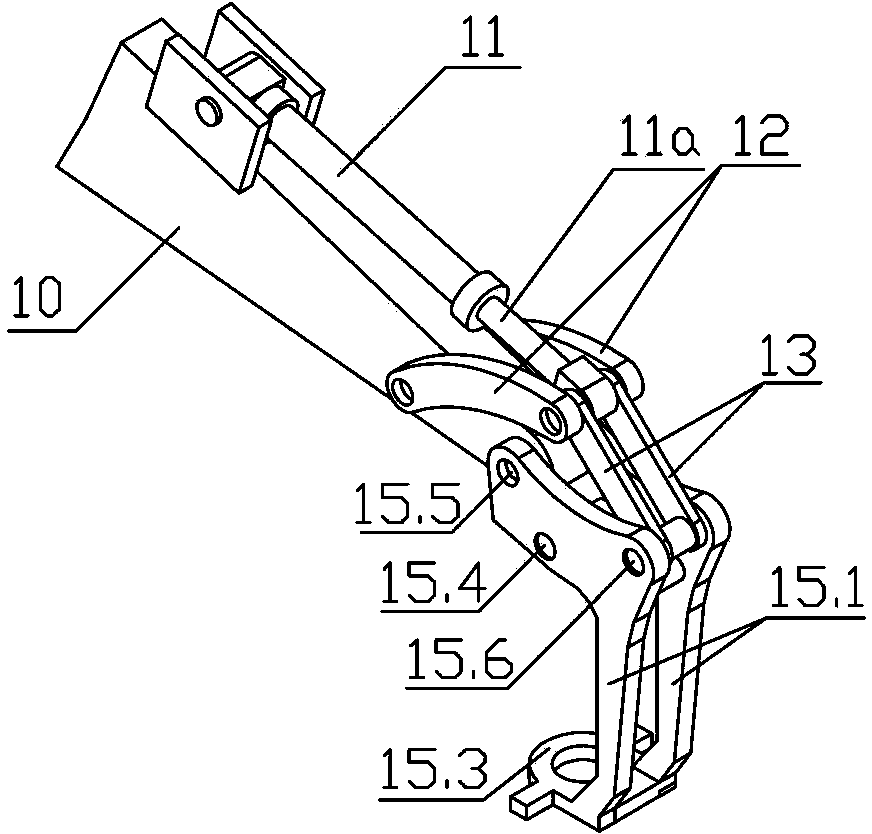

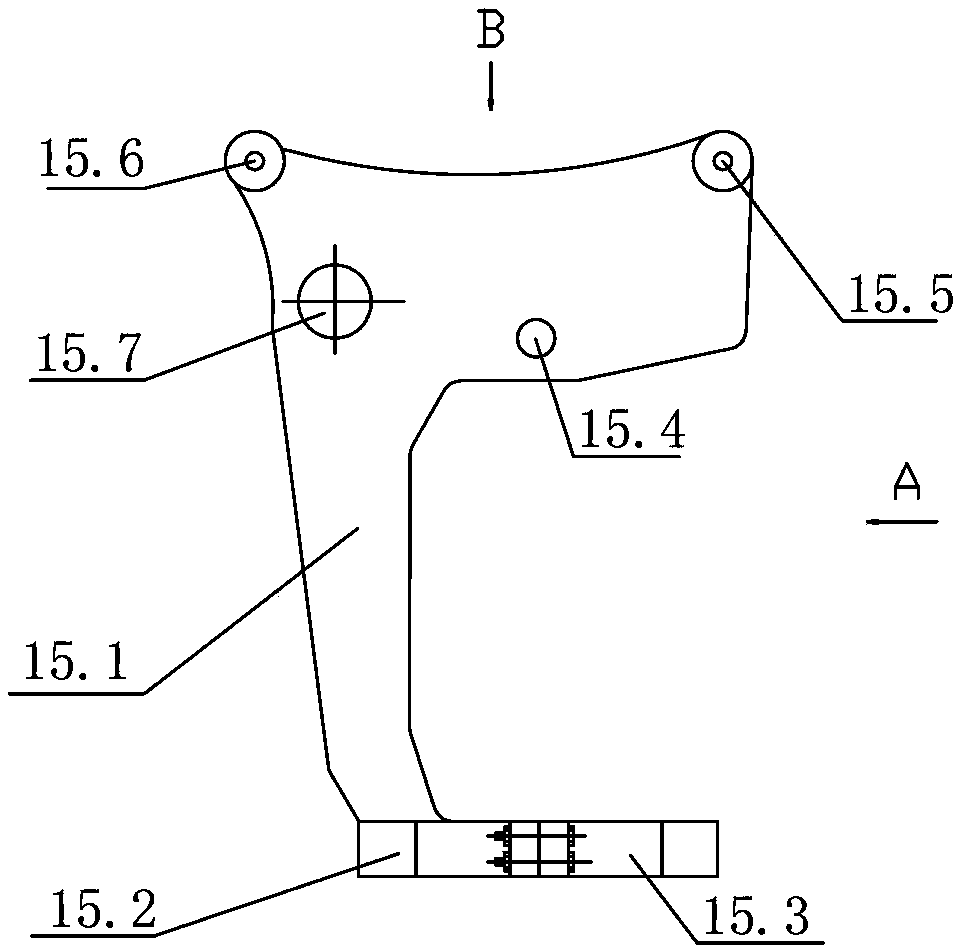

[0018] The mobile cantilever material sampler shown in the figure includes a car chassis 2 with a driving device (with wheels 1 under the car chassis 2), a slewing support 3 and an operating room 6 arranged in the middle of the car chassis 2, hinged to The primary support arm 7 on the mounting seat 5 of the automobile chassis 2 is hinged to the secondary support arm 10 on the primary support arm 7, and is hinged to the lower joint 7.1 of the automobile chassis 2 and the primary support arm 7 A primary oil cylinder 8, a secondary oil cylinder 9 hinged between the upper joint 7.2 of the primary support arm 7 and the secondary support arm 10, the secondary support arm 10 is also hinged with a tertiary oil cylinder 11, the The end of the piston rod 11a of the three-stage oil cylinder 11 is hinged with one end of the rocker 12 and one end of the connecting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com