Plane type camera calibration method

A camera calibration and planar technology, applied in image analysis, image data processing, instruments, etc., can solve problems such as low-level, complex stability, and large amount of calculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

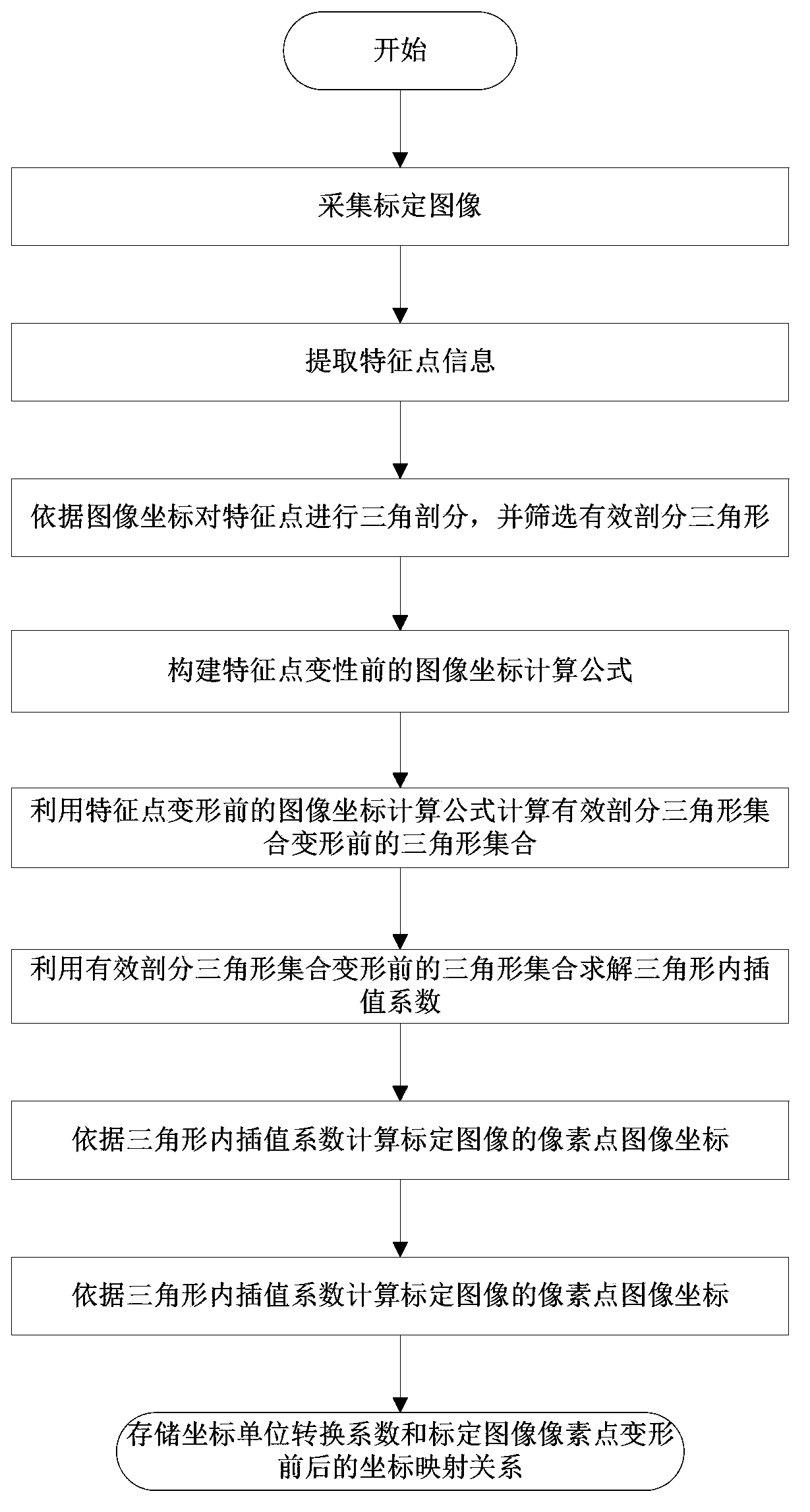

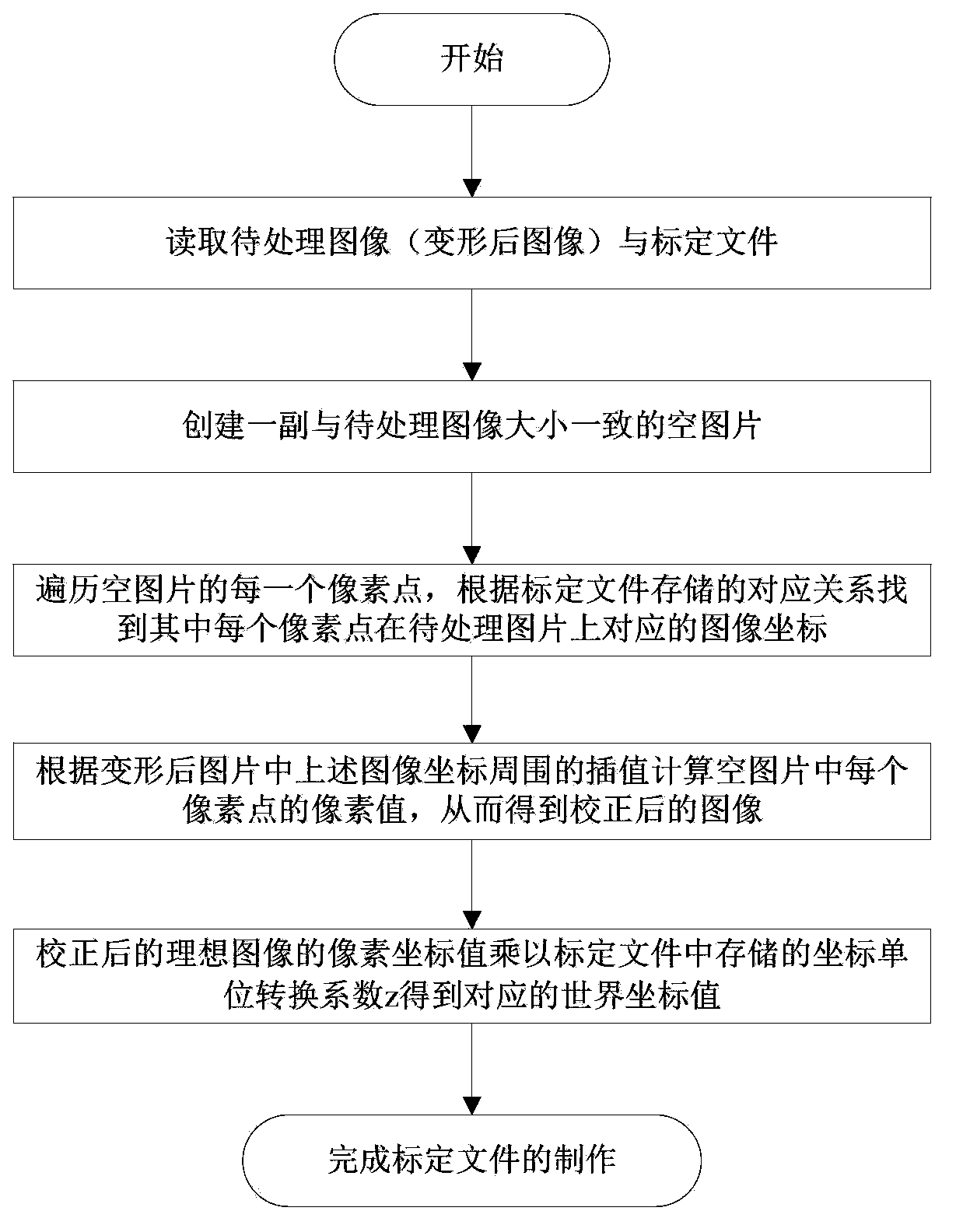

[0042] The core idea of the plane calibration algorithm based on subdivision triangle interpolation proposed by the present invention is to use the calibration feature point set to effectively subdivide the triangle segmentation calibration image to perform linear interpolation calculation in the local area to complete the camera calibration, thus replacing the traditional method. A task that can only be accomplished by fitting calculations of bivariate high-degree polynomials.

[0043] The effective Delaunay subdivision triangles of the feature point set are filled and evenly distributed on the entire scale of the calibration image, and the influence of the overall image distortion on the local area of each subdivision triangle is negligible (local distortion resistance). These two properties provide a method for camera calibration based on plane feature size measurement: estimate the position of all calibration feature points on the image before deformation, and calculate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com