Heating roller heat-setting treatment device

A processing device and heating roller technology, applied to electrical components, circuits, battery pack components, etc., can solve problems such as difficult diaphragm winding operation, reduced diaphragm production speed, and increased traction control complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

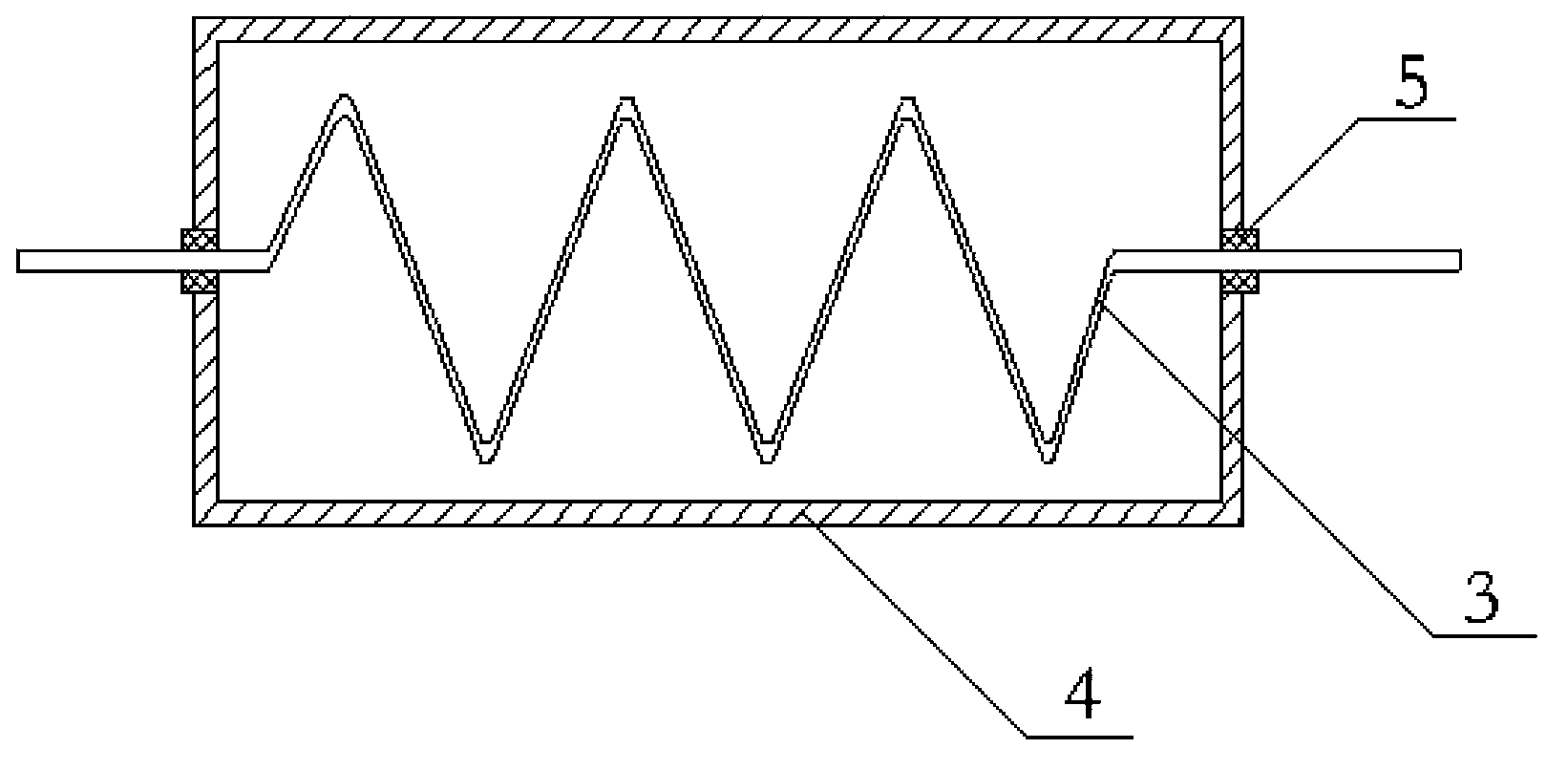

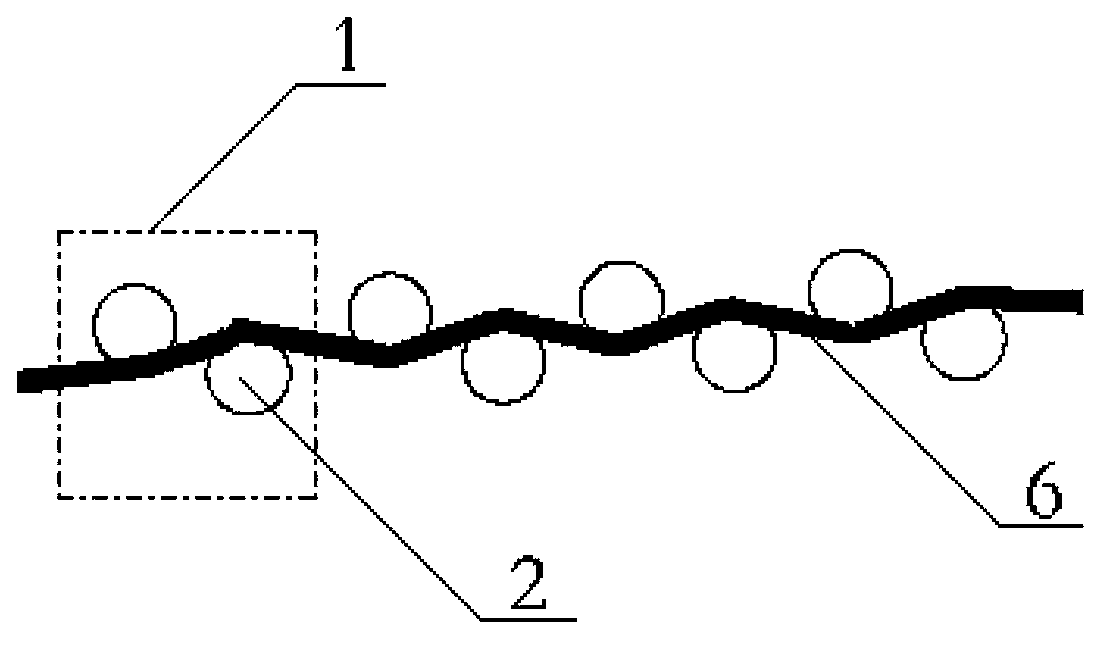

[0020] A heating roller heat setting processing device, which is composed of 4 groups of heating roller heat setting processing parts 1, each group of heating roller heat setting processing parts 1 includes two heating rollers 2, the two heating rollers 2 are the same size and shape, arranged up and down The heating roller 2 is composed of a heat exchange tube 3, a bearing 5, and a cylindrical heating roller shell 4. The heat exchange tube 3 is fixed inside the heating roller shell 4, and the bearings 5 are respectively arranged in the The two sides of the heating roller shell 4 are axially connected with the heating roller shell 4.

[0021] Wherein, the distance between each group of the heating roller heat setting processing parts 1 is 2.5 times the center distance of each group of heating roller 2 in the pulling direction of the diaphragm 6, and each group of heating roller heat setting processing parts 1 has two heating The center distance of the roller 2 in the pulling dir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com