Method for producing spheroidal graphite cast iron and vehicle component using said spheroidal graphite cast iron

A technology of ductile iron and vehicle parts, applied in the field of vehicle parts, can solve the problems of rare earth price and production fluctuation, price and supply instability, etc., and achieve the effect of stable supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

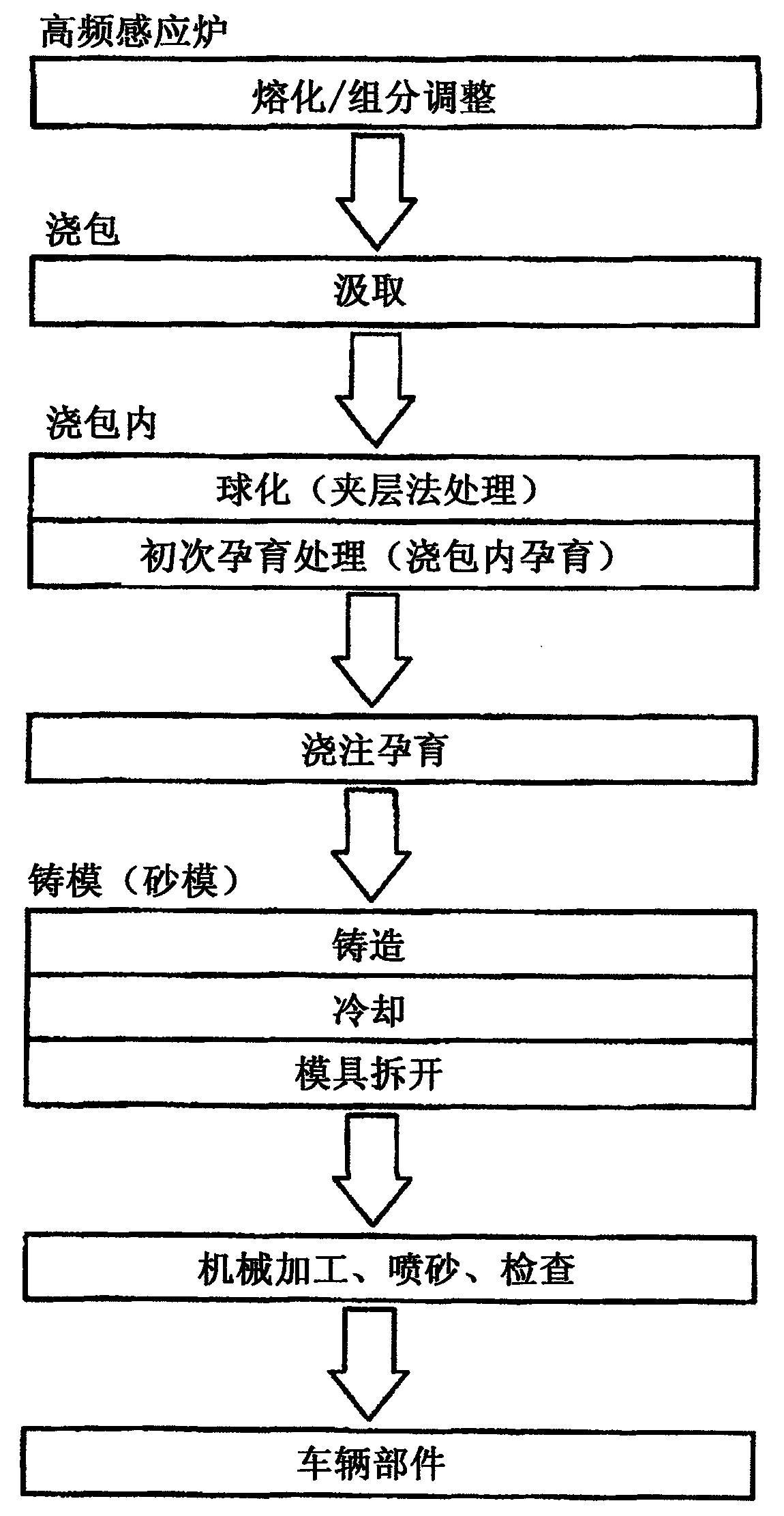

[0131] The present invention will be explained in more detail below with reference to examples in which the as-cast thin-walled ductile iron of the present invention is used to produce brake calipers for automobiles. However, the present invention should not be construed as being limited to the following examples.

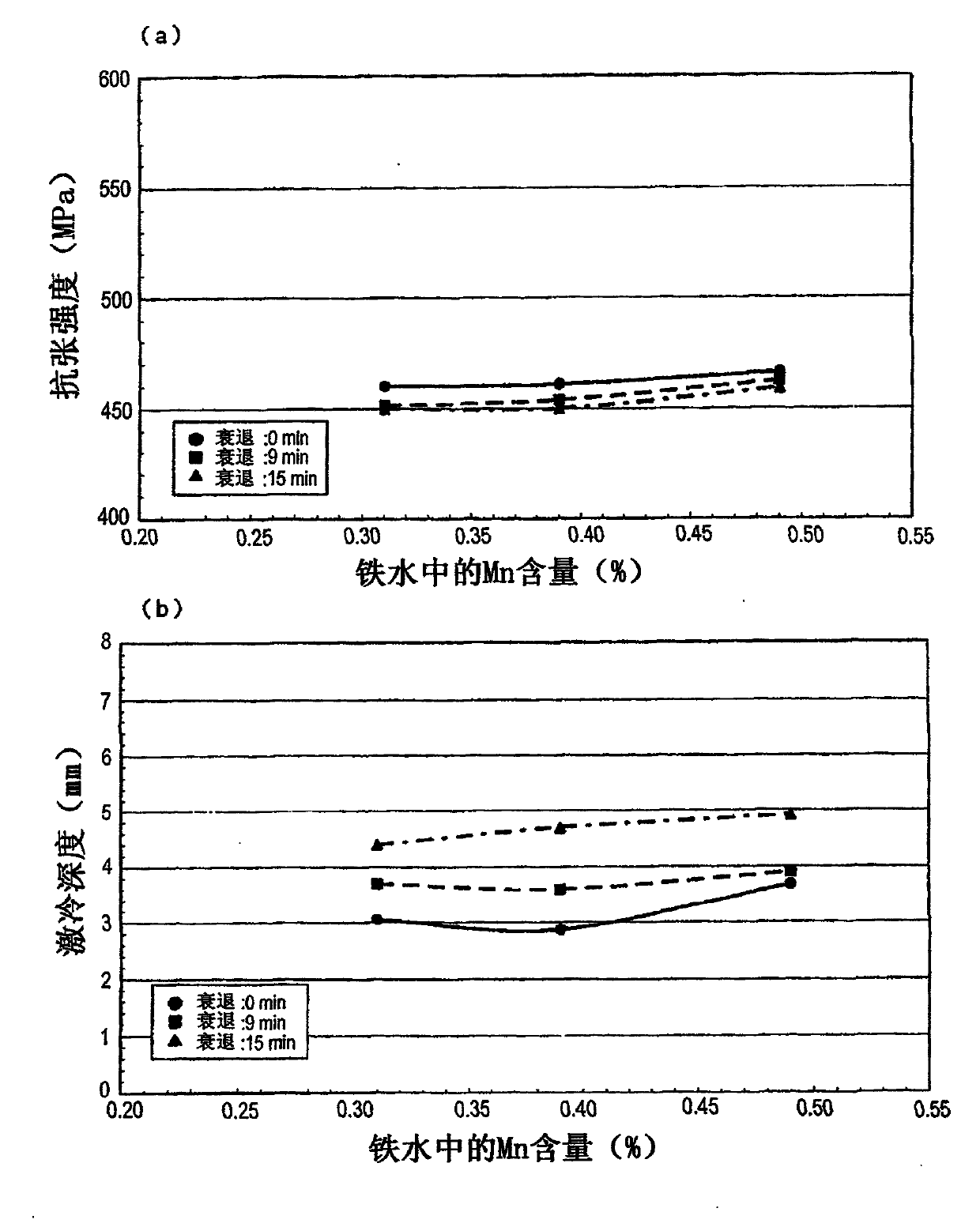

[0132] For the ductile irons of Examples (Examples 1 to 13 and Comparative Examples 1 to 8), a remelted cast iron material and an iron scrap material were used as raw materials. The ratio of recycled material to iron scrap material in raw materials is about 1:1. The raw materials are melted using a high-frequency furnace. However, C, Si, Mn, S, Cu, and Sn as additive elements are suitably added thereto to adjust the molten iron so that the molten iron contains a composition corresponding to FCD450 (JIS G5502), that is, the molten iron has a composition containing: In terms of mass %, 3.0 to 4.5% of C, 2.0 to 3.0% of Si, 0.2 to 0.4% of Mn, 0.006 to 0.020% of S, 0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com